TM 9-3419-234-14&P

SECTION III

SECTION II

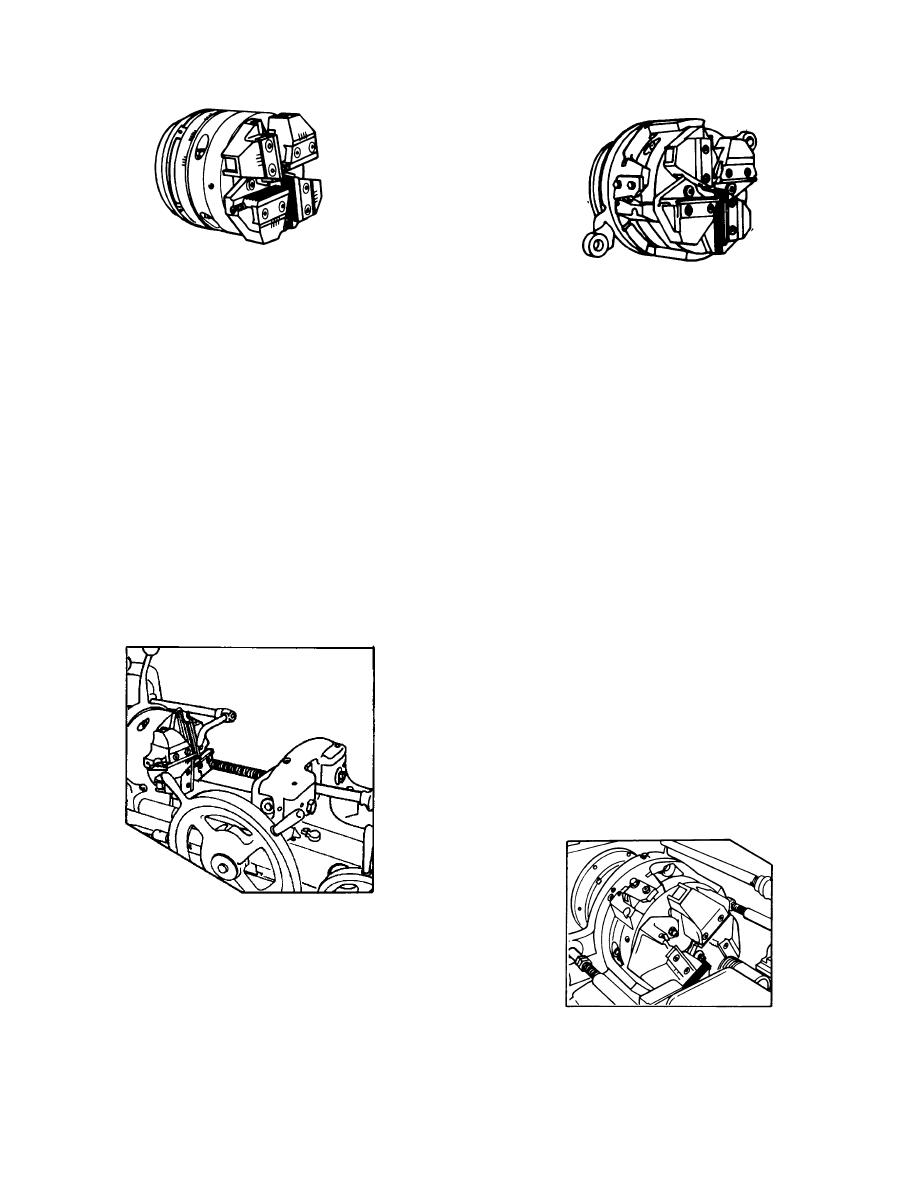

THE S TYPE

THE R TYPE

Fig 32

a. The R type Heat Treated Heads are designed for

Fig. 34

commercial and heavy-duty threading applications and are

a. The type "S" Receding Chaser Threading Head is

considered the standard heads m the series. Their initial

recommended for producing taper threads of maximum

cost is lower and they feature unusually wide range

accuracy and of long lengths As the receding movement

coverage.

of the chaser produces the cutting action by the throat

section only, cutting strains are reduced to a minimum.

b. Their rugged construction and design simplicity

This feature prolongs chaser life and permits the use of

assures trouble-free operation, long life and positive

narrow, more economical chasers. Of greater importance

performance. The standard heads are available in 9/16" to

is the production of truly conical (no chaser leave off mark)

2-1/2" models while a 4" and 6" model are available for

threads which will meet API specifications. The die head

heavy duty precision threading of large diameter

must be applied to a machine equipped with leadscrew or

workpieces. These heavy duty heads are similar in

power feed.

construction to the smaller heads but they both use two

head opening springs in balanced positions to assure

b. Two adjustable trip bars attached to the machine

uniform and positive opening action when threading

carriage front actuate the operating ring of the 1-1/2", 2",

maximum diameters and coarse pitches. The 6" R also

2-1/2" and 6" S Heads as the work advances into the

features a six chaser design which provides greater

head. With the 9/16" and 3/4" heads, the operating ring is

support for the workpiece, more free cutting action, and

actuated by a yoke. The movement of the cam on the

eliminates out-of-roundness common to large diameter

operating ring along the cam follower allows the chasers to

threading.

recede at a uniform rate, and thus produces a tapered

thread corresponding to the taper of the cam. The head

c.

Specifications can be found on pages 32, 33 and 34.

opens automatically when the cam trips at the end of the

cam follower. Special operating rings with cams for cutting

other than 3/4" taper per foot are available for the 9/16"

head. With the 3/4", 1-1/2", 2", 2-1/2 and 6" heads,

threads can be cut with various degrees of taper by the

use of the proper cams which can be quickly and easily

changed. Straight threads can also be cut by employing a

straight cam, and reverse taper threads from the large

diameter of the taper to the small diameter can be cut by

the use of a reverse taper cam.

c.

Specifications can be found on page 35.

Fig. 33

Fig. 35

27