TM 9-3431-254-14&P

L-57, L-77

Series

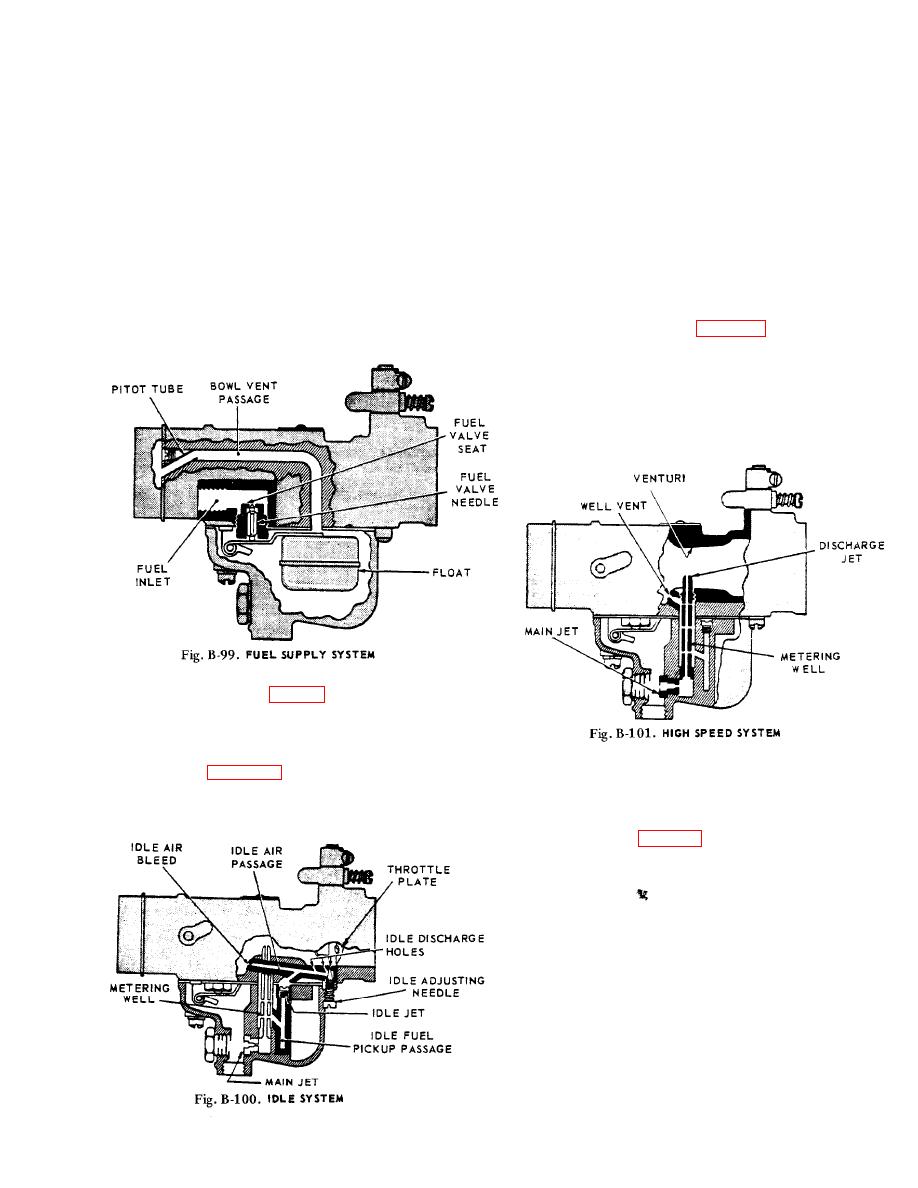

CARBURETOR

MODEL 87A8

OPERATION and SERVICE

main jet. Fuel from the float chamber flows through the

DESCRIPTION

main jet into the metering well. Fuel for idling is drawn

The

87-Series is a horizontal carburetor with a con-

from this well through the calibration, or metering orifice,

centric fuel bowl. It is a "balanced" carburetor, because

in the center of the idling jet. AS the fuel reaches the

all air for fuel chamber and metering well ventilation and

idling channel it is mixed with air which is admitted

idling must come through the air cleaner. Air cleaner

through a calibrated orifice in the channel from the inside

restrictions have a minimum influence on the fuel-air ratio

of the air intake to form an emulsion. This emulsion is

when a carburetor is thus "balanced".

discharged into the air stream, to form the idling mixture,

through two holes one of which is controlled by the idle

The main jet and discharge jet are centrally located. The

adjusting needle. Turning the adjusting needle counter-

metering well which completely surrounds the discharge

clockwise (out) permits more of the emulsion to reach the

jet is in the center of the fuel bowl assembly. This con-

air stream and make the idling mixture richer while turning

struction permits extremely high angle operation in any

the needle in (clockwise) cuts off the amount of the emul-

direction.

sion reaching the air stream and makes the mixture leaner.

The venturi, which is part of the throttle body casting,

measures the volume of air that passes through the car-

buretor. In selecting the venturi size, the smallest size

As the throttle is opened, the suction on the idling system

that will permit full power development should be used.

diminishes, but the increased volume of air entering the

engine through the venturi creates sufficient vacuum

(suction) on the discharge jet to draw an emulsion of fuel

and air from the metering well which receives its fuel from

the main jet and its air from the well vent. The flow

characteristics of the discharge jet are influenced by the

size, location, and number of holes in the sides of that

part of the jet which is in the metering well, as well as by

OPERATION

FUEL SUPPLY SYSTEM (Fig. B-99)

Fuel under normal pressure entering the float chamber

through the fuel valve seat is controlled by the twin float

which, moving on its axle, closes the needle valve when

the fuel reaches the proper level in the bowl.

the sizes of the discharge jet orifice, the size of the main

jet, and the size of the well vent. The well vent is located

in the air intake and permits air to enter the top of the

At idling speeds the throttle plate is almost closed, thus a

metering well around the outside of the discharge jet. The

very high suction exists at the edge of the throttle plate

flow of fuel through the main jet is controlled by the size

where the idle discharge holes are located. All fuel for

of main jet opening.

idling and part throttle operation is supplied through the

Starting a coId engine requires a much richer mixture of

fuel and air. Moving the choke lever to close the choke

plate restricts the air entering the carburetor (except at the

pitot tube, Fig. to the bawl vent) and increases the

suction on the idling system which makes the mixture

richer.

STARTING THE ENGINE

Before cranking the engine, the carburetor throttle should

be opened a little to expose both idle discharge holes to

suction The choke should be fully closed until the engine

starts, then opened a little to prevent stalling from being

over-choked, then when the engine is fully warmed up the

choke can be returned to wide open position and the

throttle closed to the idling position.

ADJUSTMENTS

Adjust the throttle stop screw to obtain the desired idling

speed by turning screw in (clockwise) to increase speed

and out (counter-clockwise) to decrease engine speed.

B-73