TM 9-4110-255-14

d. Drain and Fill Engine Crankcase. The engine contains preservative oil that must be drained and replaced with

the appropriate lubricating oil for the operating conditions.

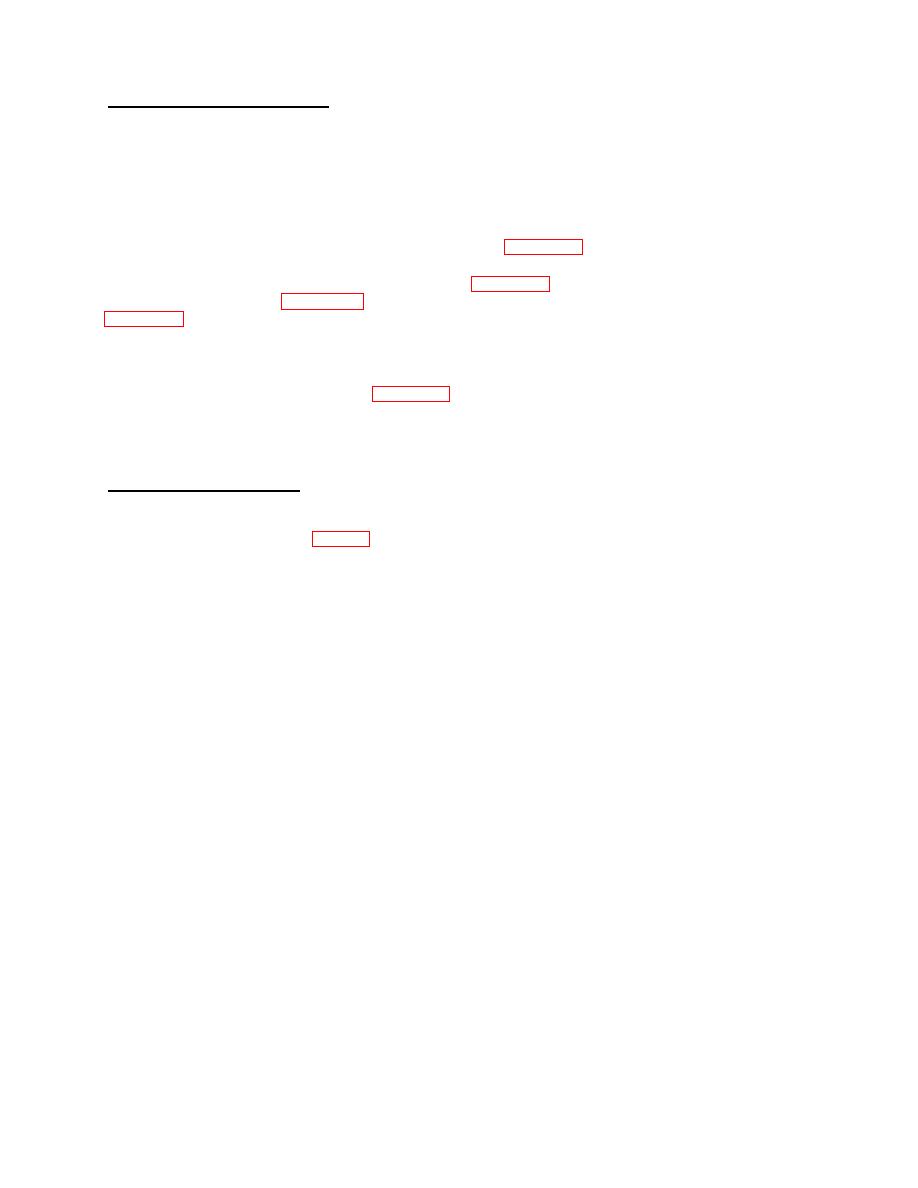

(1) Place drain pan under engine drain hose (4).

(2) Remove plug (5) and plug (6). Wait for all preservative oil to drain out. Contact your local environmental officer

for guidance on how to properly dispose of preservative oil in accordance with local regulations.

(3) Clean plug (6) and drain hose (4) end with a wiping rag (3, appendix E) and install the plug.

(6) Fill engine (7) with 0.85 qt. (0.8 1) lubricating oil (11, appendix E) if operating temperatures are 0F to 50 F (-

18 C to -150 C), or (10, appendix E) if operating temperatures are 5 F to 1040 F (-15 C to 400 C), or (12,

(7) Install plug (5).

e. Check and adjust V-belts as necessary (para 4-38).

CAUTION

Using excessive force when opening or closing valves can cause damage to the valve seats.

f. Refrigeration System Valves. The refrigeration system has been pumped down and the valves must be properly

positioned before operating the refrigeration unit.

(1) Fully open both stop valves (1, fig. 4-4) and (2).

(2) Remove two caps (3) and fully open two isolation valves (4). Install two caps.

NOTE

The compressor shut off valves can be adjusted to three positions, fully closed to block the

refrigerant tubes and isolate the compressor and service port, fully open to allow flow from

piping to compressor but not the service port, and cracked (one turn closed from fully open) to

allow flow from piping to compressor and service port on valve.

(3) Remove two caps (5) and fully open two shut off valves (6). Install two caps.

g. Close both side condenser doors and front door.

4-5