TM 9-4110-255-14

5-43. INJECTION PUMP TESTING, REPLACEMENT, AND ADJUSTMENT.

This task covers:

a. Testing

b. Removal

c. Installation

d. Adjustment

INITIAL SETUP

Tools:

Materials/Parts:

Fuel Delivery Sight

Gasket

8, Section III, Appendix B

52, Appendix G

Materials/Parts:

Gasket(s) (0.2) (As Required)

49, Appendix G

Gasket(s) (0.1) (As Required)

Wiping Rags

54, Appendix G

9, Appendix E

Gasket(s) (0.3) (As Required)

Equipment Conditions:

60, Appendix G

Gasket

Refrigeration unit shut down (para 2-7) and battery

17, Appendix G

disconnected (para 4-35).

Left side door open.

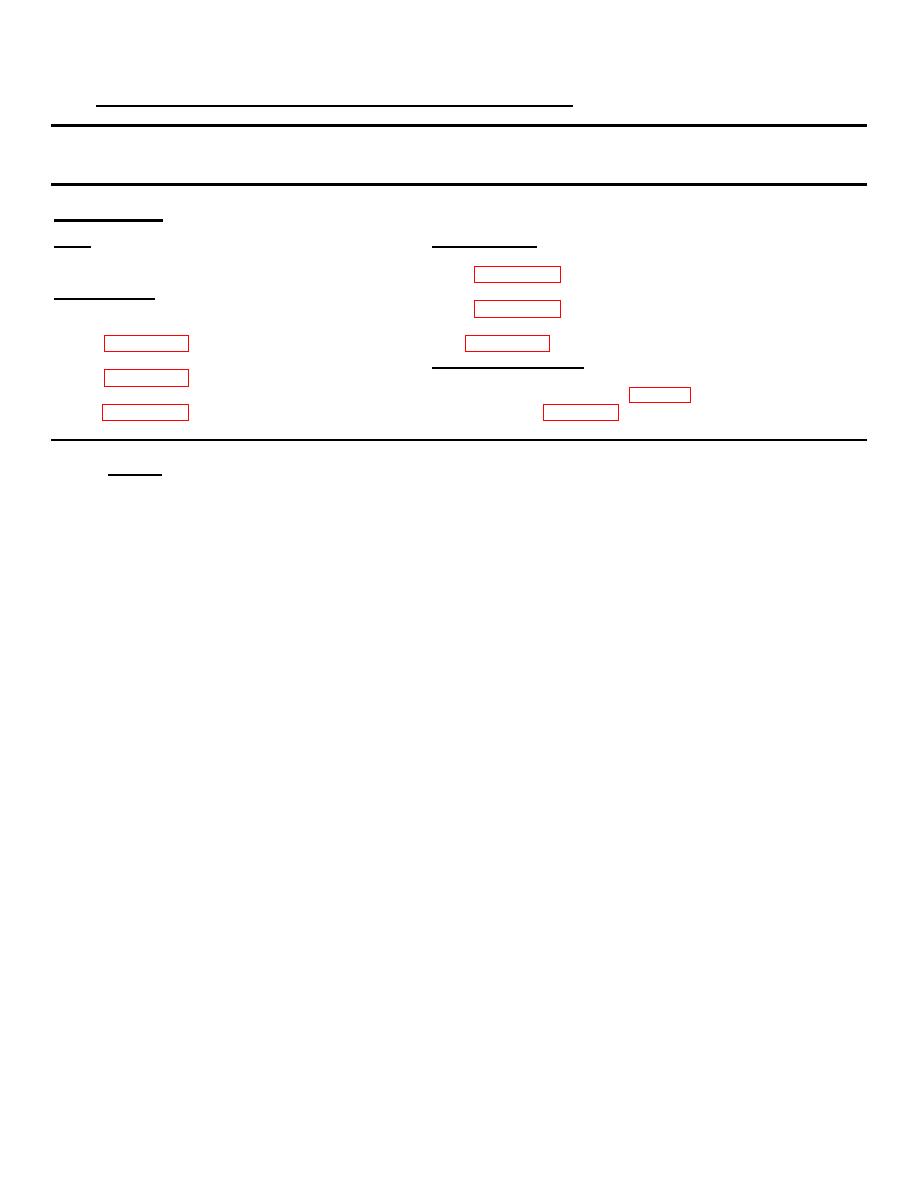

a. Testing.

(1) Remove screw (1), flat washer (2), and cylinder casing (3).

(2) Remove three screws (4), cover (5), and gasket (6). Discard gasket.

CAUTION

Always use two wrenches when loosening the fuel pipe to prevent turning the nozzle or injection

pump fitting.

(3) Loosen two flare nuts (7) and remove fuel pipe (8).

(4) Connect a pressure gauge with a reading capacity of 8,532 psi (58,871 kPa) full scale to the M12 x 1.5

injection pump fitting (9).

(5) Set and secure the manual shut down lever (10) to the full open position (right).

WARNING

Before applying pressure to the gauge, be sure that all connections are tight, and that the fittings

are not damaged. Fluid escaping from a very small hole can be almost invisible. Use a piece of

cardboard or wood, rather than hands, to search for suspected leaks.

(6) Monitor the pressure gage reading and slowly turn the engine flywheel (11) clockwise. Note the maximum

pressure indicated on the gage. If the pressure does not reach 4,266 psi (29,435 kPa) or above, the

injection pump (12) must be replaced.

5-84