TM 9-4110-258-13

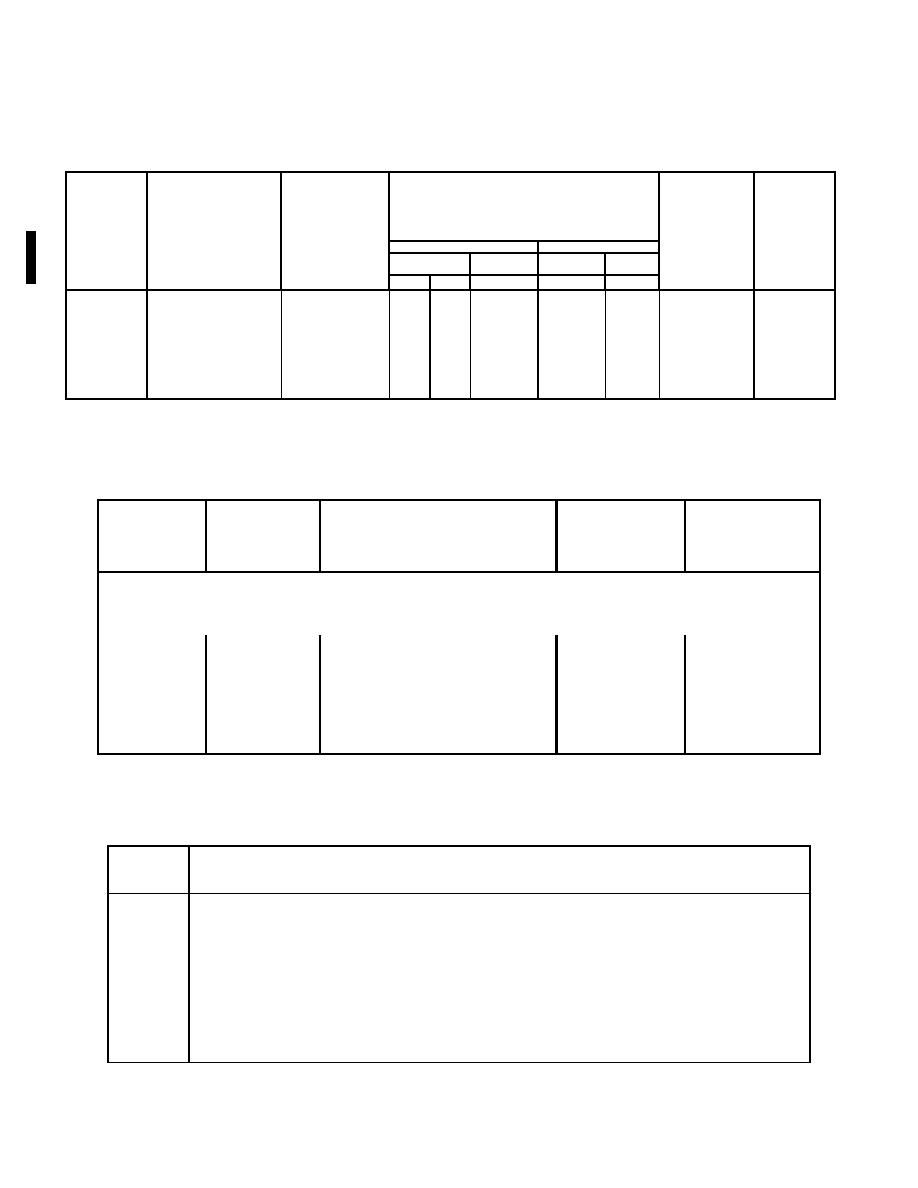

Section II. MAINTENANCE ALLOCATION CHART

FOR

REFRIGERATION UNIT, MECHANICAL, 9K BTU, ELECTRIC MODEL F9000RE - continued

(1)

(2)

(3)

(4)

(5)

(6)

GROUP

COMPONENT/

MAINTENANCE

MAINTENANCE LEVEL

TOOLS AND

REMARKS

NUMBER

ASSEMBLY

FUNCTION

EQUIPMENT

CODE

REFERENCE

FIELD

SUSTAINMENT

CODE

DIRECT

GENERAL

DEPOT

UNIT

SUPPORT

SUPPORT

C

O

F

H

D

DOORS/COVER

Inspect

0.1

Service

0.5

1, 4

Repair

1.0

1, 4

Replace

1.0

1, 4

BOLTS, BARREL

Inspect

0.1

Service

0.1

1, 4

Replace

0.5

1

Section III. TOOLS AND TEST EQUIPMENT

FOR

REFRIGERATION UNIT, MECHANICAL, 9K BTU, ELECTRIC MODEL F9000RE

(1)

(2)

(3)

(4)

(5)

TOOL OR TEST

MAINTENANCE

NOMENCLATURE

NATIONAL STOCK

TOOL NUMBER

EQUIPMENT

LEVEL

NUMBER

REFERENCE

CODE

NOTE

Standard tools and teat equipment in the following kits are adequate to accomplish the maintenance

functions listed in Section II.

1

O

Shop Equipment (1), Automotive Vehicle

SC 4910-95-CL-A74

2

O

Comb, Fin

5120-00-916-6197

3439-01-037-7268

3

O

Heat Gun

4

F

Tool Kit, Service, Refrigeration Unit

5180-00-597-1474

SC 5180-90-CL-N18

5

F

Recovery and Recycle Unit, Refrigerant

4130-01-359-4516

6

F

Nitrogen Regulator

6680-00-503-1327

Section IV. REMARKS

FOR

REFRIGERATION UNIT, MECHANICAL, 9K BTU, ELECTRIC MODEL F9000RE

(1)

(2)

REMARKS

REMARKS

CODE

A

Repair at unit maintenance level is limited to replacement of electric coil.

B

Repair at direct support maintenance level is limited to replacement of valve body.

C

Inspection at operator maintenance level is limited to condenser fan only.

D

Inspection at unit maintenance level is limited to evaporator fan only.

NOTE

Other than those items listed above there are no supplemental instructions or explanatory remarks

required for the maintenance functions listed in Section II. All functions are sufficiently defined in Section

I. Active time listed for maintenance task functions are with the refrigeration unit in off-equipment

position.

Change 1

B-8