TM 9-4120-357-14

(5) Compare the pressure and temperature readings with those in Table 5-3. Temperature should be approximately

10F (5.5C) higher than that shown in the table for the equivalent pressure reading.

(6) If superheat setting is less than 10 (5.5 ) above saturation temperature shown in the table, adjust the expan-

F

C

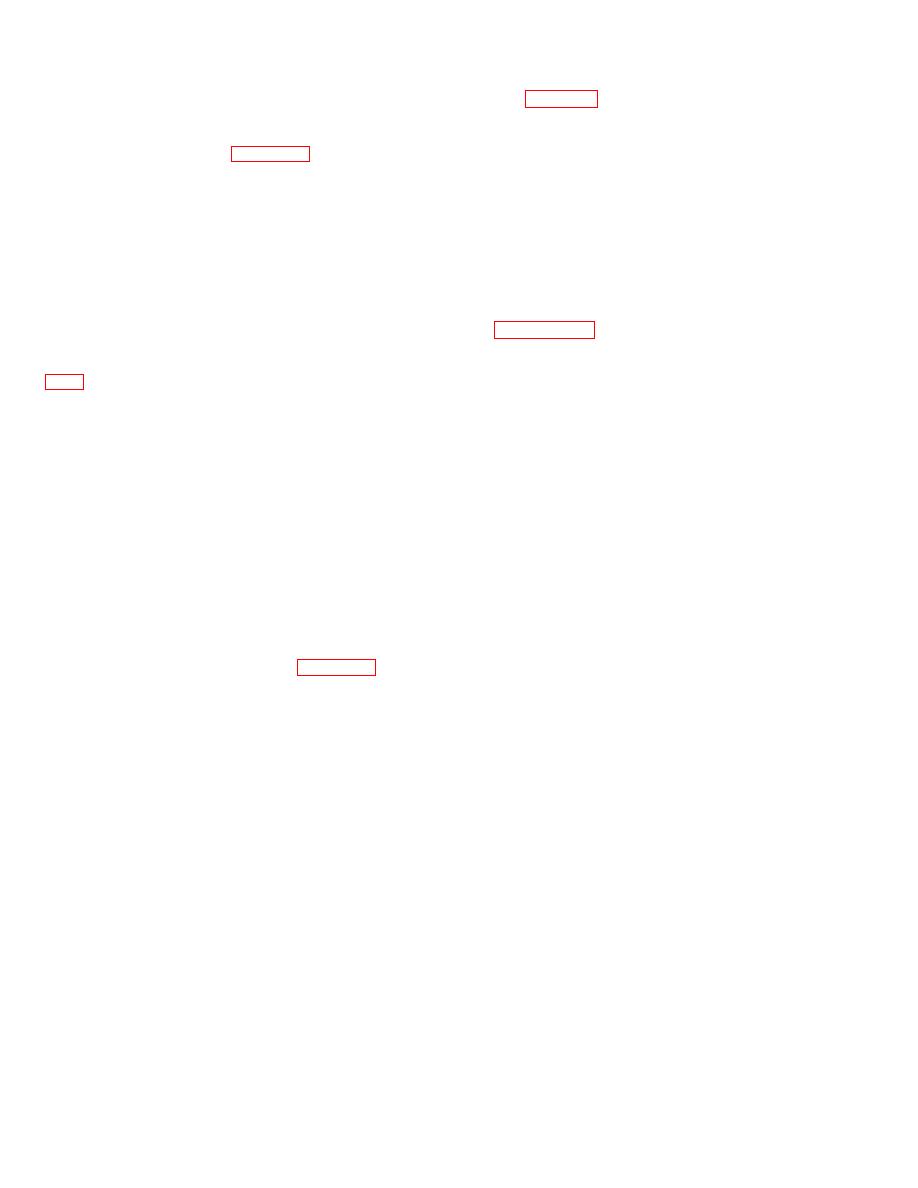

sion valve as follows: (See Figure 5-4.)

(a) Remove the hexagonal seal cap (2) from the side of the power assembly (1) and loosen bonnet set (3) .

(b) Turn the adjusting stem (5) two complete turns to change superheat one degree (F) . Turn clockwise to raise,

and counterclockwise to lower, the superheat setting. Do not turn more than two complete turns, then wait for two min-

utes for temperature to stabilize before observing temperature and pressure readings.

(c) When the proper setting is obtained, replace the screw cap and seal on the valve adjusting stem (5) .

(7) Remove the thermometer or thermocouple probe from the suction line, and replace insulating material. Turn the

suction service valve off, and remove the pressure gage. Replace cap on gage port.

d. Discharging the System. Whenever a leak is detected or a refrigeration component must be replaced, you must

discharge all gas from the refrigeration system in accordance with paragraph 5-6.

e. Removal. Remove the expansion valve from the air conditioner as directed in the following steps: (See Figure

(1) Remove insulation and band clamp from sensing bulb. Carefully detach bulb and capillary tube.

(2) Remove two capscrews (10) securing the power assembly (1) to the valve body (9) . Remove the power assem-

bly, capillary tube and sensing bulb.

(3) Remove two capscrews that secure the valve body to the support bracket. Detach equalizer line, if applicable.

CAUTION

Maintain a 1-2 CFM (0.5 - 1M3) flow of dry nitrogen through the refrigeration system to

prevent oxidation and scaling when brazing or debrazing components.

(4) Debraze tubing connections. Remove valve body (9) .

f. Installation. Install the expansion valve in accordance with the following procedures:

(1) Disassemble the valve by removing two capscrews (10) that secure the power assembly (1) to the valve

body (9) , and separate the two.

(2) Install the valve body in the support bracket, and secure with two capscrews, finger tight. Connect tubing.

(3) With dry nitrogen flowing through the refrigeration system braze tubing joints. Let cool. Tighten capscrews.

(4) Install power assembly (1, Figure 5-4) on valve body, being careful to fit lugs on the cage assembly (7) into

the cavities in the body (9) . Secure the two capscrews (10) . Connect equalizer line, if applicable.

(5) Wrap the capillary tube with a double thickness of insulating tape, being careful to avoid kinking the tube.

(6) Carefully lead the sensing tube to its position on the suction line. Clamp in position 45 degrees below the hori-

zontal centerline of the suction line. Cover suction line, sensing bulb and clamp with insulating material.

(7) Carefully form the capillary tube along adjacent piping, and tape to support.

g. Purging the System.

CAUTION

Whenever the refrigeration system has been opened to the atmosphere, you must install

a new drier-strainer (dehydrator) before purging and recharging the system.

5-54