TM 9-4120-357-14

c. Adjusting Superheat. A refrigerant gas is said to be superheated when its temperature is higher than the evapo-

rating temperature corresponding to its pressure at saturation. When a thermal expansion valve is set for optimum su-

perheat (in this case 10 F or 5.5 C above the evaporating temperature of the refrigerant at a given pressure) the evapo-

rator coil operates at maximum efficiency. That is, the refrigerant gas does not become warm before reaching the end

of the coil, which would reduce the coil's cooling capacity, and the refrigerant does not remain in the liquid state after

passing completely through the coil, which could result in severe damage to the compressor. The superheat setting of

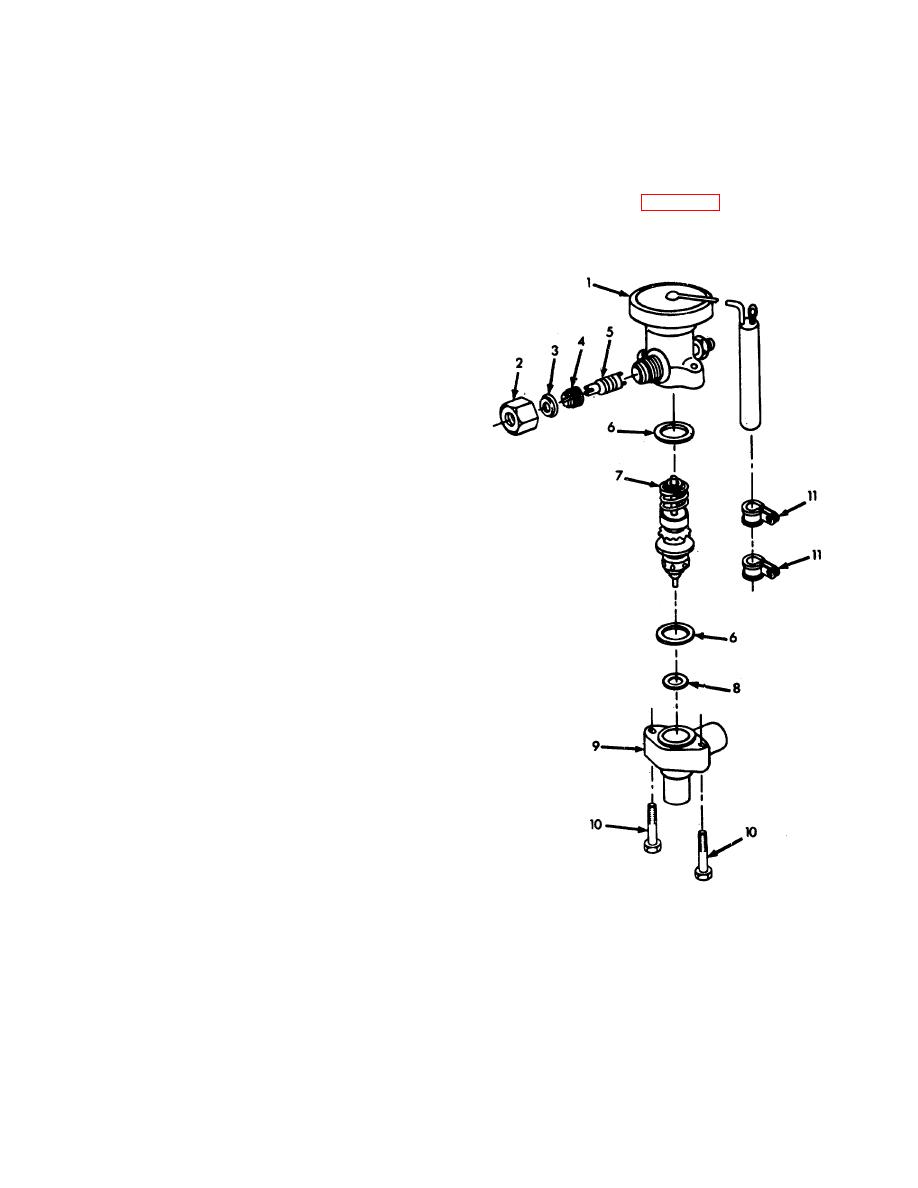

an expansion valve can be adjusted by varying the setting of a compression spring (7, Figure 5-4) in the power assem-

bly of the valve. This spring tends to hold the valve dosed against the pressure in the sensing bulb and capillary tube;

therefore, the greater the spring pressure, the higher the superheat. Check superheat, and adjust if necessary, in ac-

cordance with the following procedure:

(1) Remove insulation from a spot on the suction

line near the sensing bulb of the expansion valve.

(2) Install an accurate thermometer or the probe

of a thermocouple on the bare spot, using a small gob of

thermal mastic if available to improve conductivity.

Tape the thermometer bulb in position, and cover with

insulating material.

(3) Connect a suitable pressure gage to the gage

port of the suction service valve, and open the valve.

(4) Operate the air conditioner in the cooling

mode for about 30 minutes, observing the thermometer

or thermocouple dial to see that the temperature has

stabilized. When the temperature has remained the

same for at least two minutes, record the temperature

and pressure.

1.

POWER ASSEMBLY

2.

CAP, SEAL

3.

BONNET SEAL

4.

PACKING SEAL

5.

ADJUSTING STEM & PACKING

6.

GASKET, BODY FLANGE

7.

CAGE ASSEMBLY

8.

GASKET, SEAL

9.

FLANGE, BODY

10.

SCREWS, CAP

11.

CLAMP ASSEMBLIES

Figure 5-4. Typical Expansion Valve

5-51