TM 9-4120-388-14

OPERATOR'S MAINTENANCE INSTRUCTIONS

Section I. LUBRICATION INSTRUCTIONS

3 - 1 . GENERAL.

a. The 18,000 BTU/HR Air Conditioner and its major components are designed so that very little lubrication is re-

quired during their serviceable lifetime. The refrigerant compressor and its drive motor are hermetically sealed

in a single container; sealed bearings are incorporated in the drive motor; and the compressor crankcase con-

tains a lifetime charge of oil. Sealed bearings are incorporated in the evaporator and condenser fan motor.

b. The only operator lubrication required is that necessary to relieve stiffness or binding of the louver blades in

the evaporator intake and discharge grilles or the turnbutton fasteners associated with the fabric cover on the

back of the cabinet. Sparingly apply a light machine oil and work it into the joints or pivots involved. Blot up all

excess oil with a cloth or paper towel. Report stiffness or binding of all other operational controls to unit mainte-

nance for appropriate action.

Section Il. TROUBLESHOOTING PROCEDURES

3-2. USE OF TABLE. Table 3-1 contains troubleshooting instructions designed to be useful in diagnosing and correct-

ing unsatisfactory operation or failure of the air conditioner.

a. The table lists the most common malfunctions which you may find during the operation or maintenance of the

air conditioner or its components. You should perform the test/inspections and corrective actions in the order

listed.

b. This manual cannot list all malfunctions which may occur, nor all tests or inspections and corrective actions.

If a malfunction is not listed or is not corrected by listed corrective actions, notify your supervisor.

Report any trouble or corrective action beyond the scope of operator maintenance to your supervisor.

c.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. AIR CONDITIONER FAILS TO START IN ANY MODE.

Step 1. Be sure input power hasn't been disconnected.

Connect input power.

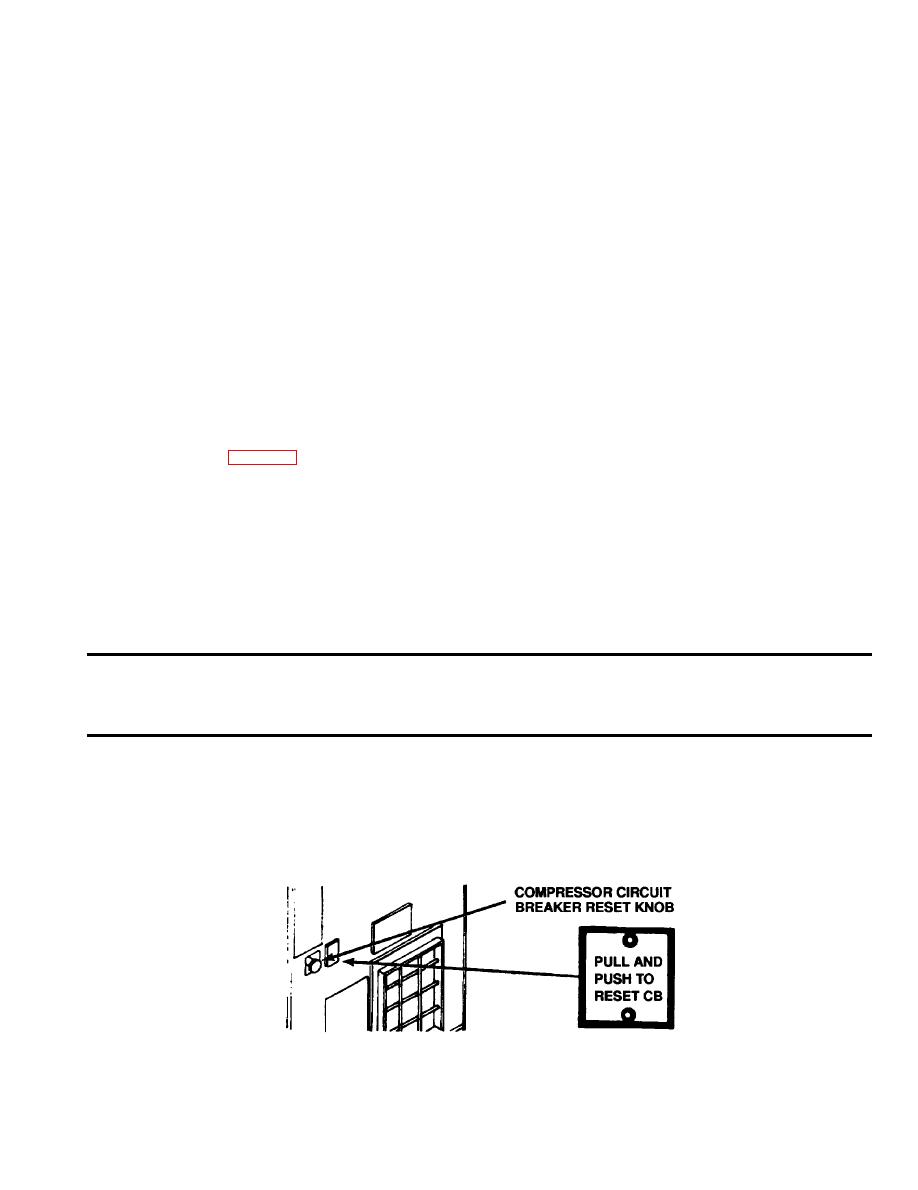

Step 2. Be sure compressor circuit breaker isn't tripped.

Slowly PULL out AND PUSH in reset knob TO RESET CIRCUIT BREAKER

NOTE

If circuit breaker continues to trip, notify your supervisor.