TM 9-4120-408-14

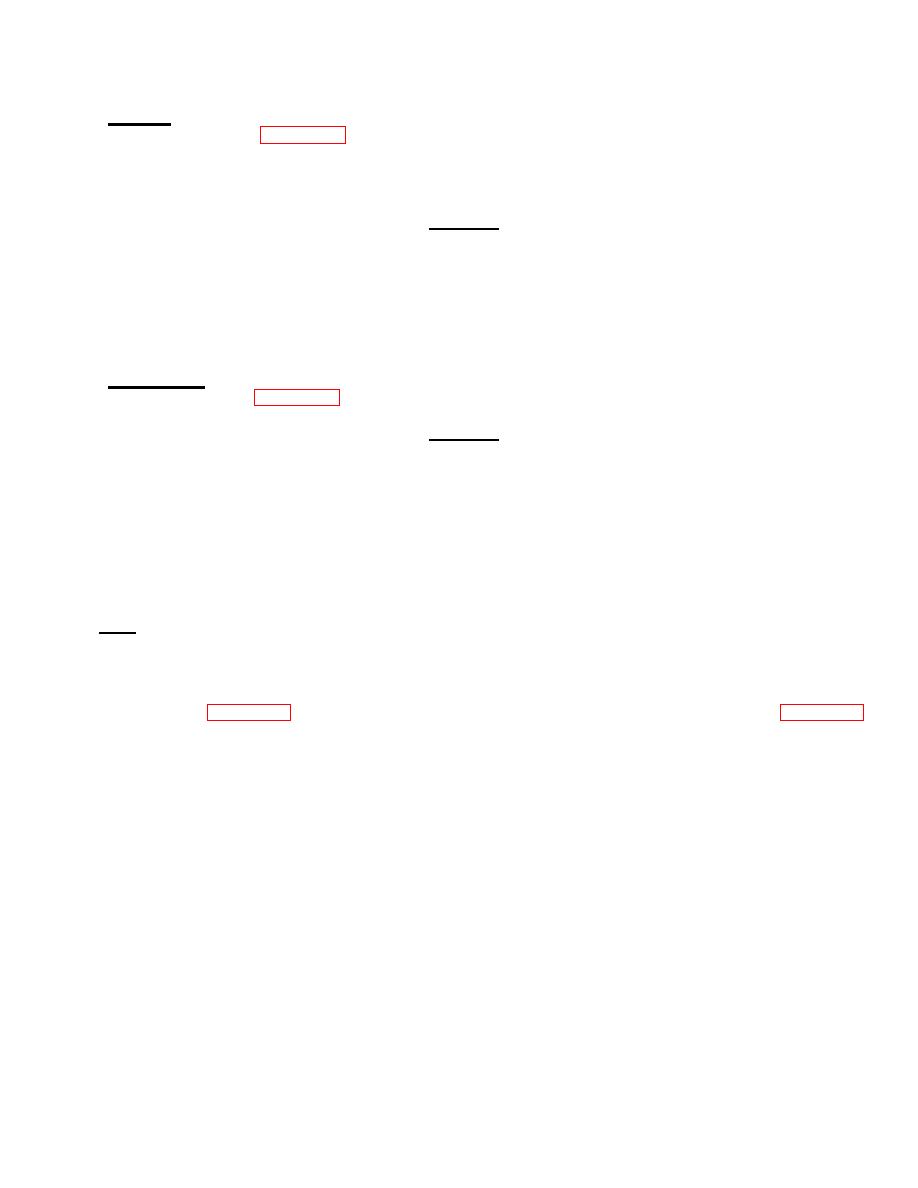

5-18. EVAPORATOR FAN ASSEMBLY MAINTENANCE. (Continued)

a.

Remove.

(1) Remove six nuts (Figure 5-13, 1), lock washers (2), flat washers (3), and cushion clamps (4). Discard lock

washers (2).

(2) Disconnect connector A106P2 (5) from EMI Electronic Filter (6).

(3) Remove eight screws (7), lock washers (8), and flat washers (9). Discard lock washers (8).

CAUTION

Do not remove evaporator fan assembly. Ensure fan assembly is stable after mounting hardware

is removed. Failure to obey this caution may result in damage to wiring harness A106J1.

(4) Remove three nuts (10), lock washers (11), flat washers (12), and screws (13). Discard lock washers (11).

(5) Remove-and discard electrical cable clamp and insulation sleeving and tag -and disconnect four wires

from connector A106J1 (14) at positions E, F, K, and L and remove and discard all tiedown straps.

(6) Remove evaporator fan assembly (15) from evaporator housing (16) and remove adhesive from

evaporator fan assembly (15).

b.

Disassemble.

(1) Loosen set screw (Figure 5-14, 1).

CAUTION

Retain bushing on motor drive shaft. Do not use bushing with a different motor. Failure to obey

this caution may result in equipment damage.

(2) Remove three screws (2), lock washers (3), flat washers (4) and slide evaporator fan housing (5) from

evaporator fan motor (6). Discard lock washers (3).

(3) Remove two nuts (7), lock washers (8), four flat washers (9), two screws (10), and evaporator fan motor (6)

from evaporator fan mounting bracket (11). Discard lock washers (8) and remove adhesive from fan motor

(6) and evaporator fan mounting bracket (11).

(4) Remove four screws (12), plate (13), and impeller (14) from evaporator fan housing (5).

c.

Test.

(1) Apply 28vdc across connector A106P2 (15) jacks C and D and check for spinning drive shaft on evaporator

fan motor (6). Replace evaporator fan motor (6) if drive shaft does not rotate.

(2) With 28vdc applied to connector A106P2 (15) jacks C and D, connect wires disconnected from connector

A106J1 (Figure 5-13, 14) positions K and L. Spinning of drive shaft on evaporator fan motor (Figure 5-14,

6) should decrease by one half. Replace evaporator fan motor (6) if drive shaft rotation rate does not

decrease.

(3) Test two wires (16) for continuity.

5-41