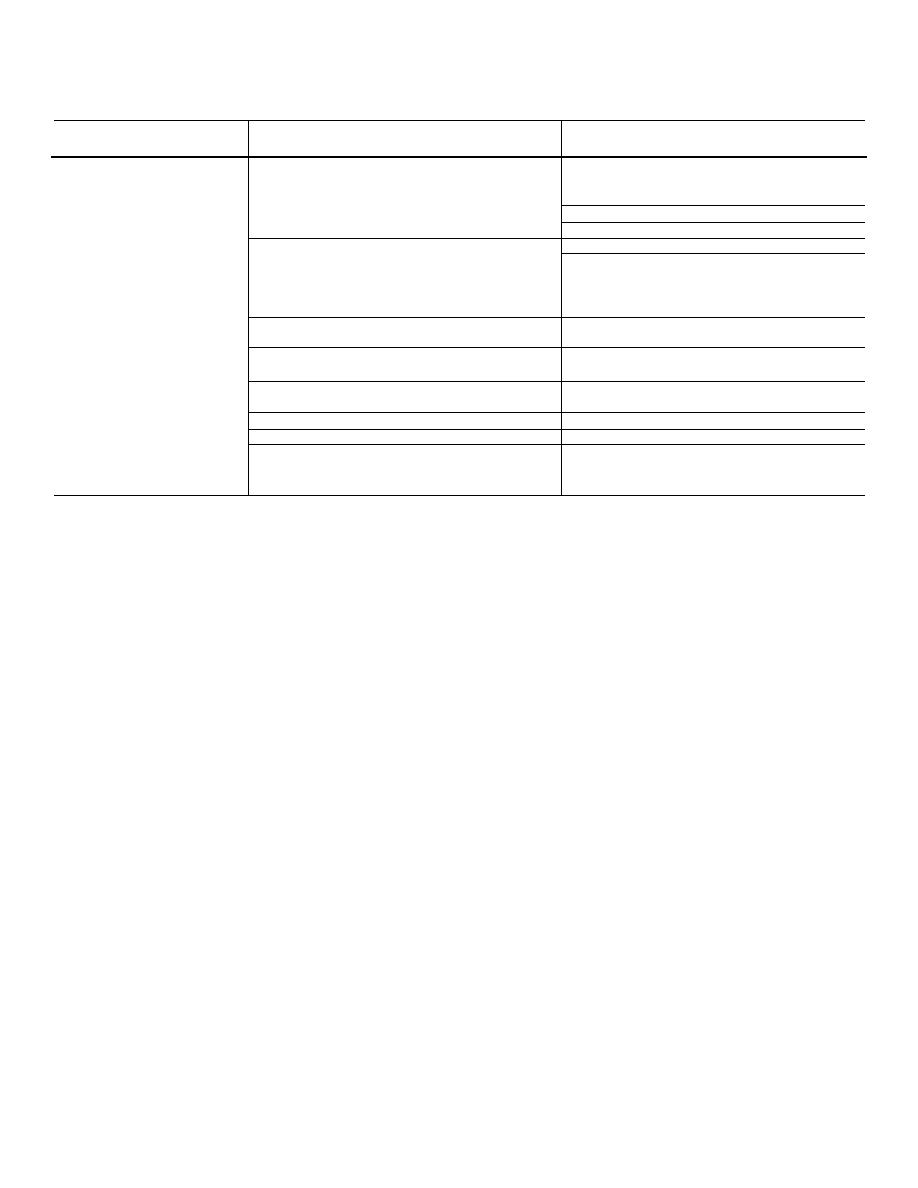

SERVICE HINTS (Continued)

Rubber nozzle hole wears

Air jet (below nozzle) is loose

Tighten air jet until fully seated

quickly or on only one side

Compound worn out.

Snake or pat exterior of cloth filter

Interior surface of filter sleeve

sleeve to drop clinging dust into

clogged with fine compound dust

compound container.

(air pressure must exhaust thru

Discord used compound

pores of cloth filter sleeve)

Add new compound

Remove worn gasket.

Dust emission or

Compound container gasket

Install new gasket Type CL-75 and

loss of compound

worn out or defective.

cement in place. Remove excess cement

to prevent difficult removal of compound

container.

Holes worn in filter sleeve.

Replace filter sleeve Type CL-88.

See filter sleeve replacement.

Top casting gasket

Tighten screws or replace gasket

loose or defective.

Type CL-102

Valve cover gasket

Tighten screws or replace gasket

loose or defective.

Type CL-93

Air flow thru

Broken Valve spring

Replace valve spring Type 17

either nozzle with

Worn rubber valve

Replace valve Type CL-92

valve lever in shut

Loosen packing gland in 1/4 turn

off position

Valve packing gland

increments until valve shuts off easily.

too fight.

See "valve replacement."

VALVE REPLACEMENT

1.

Remove hood (CL-84) by removing two retaining screws.

2.

Shake filter sleeve (CL-88) to deposit any clinging compound dust in container (CL-101). Loosen thumb nut on bail

assembly (CL-76). Swing bail to one side and remove compound container (CL-101).

3.

Remove rubber adapter and metal retainer by turning retainer (CL-96) part turn.

4.

Disconnect air line to compound casting at coupling marked "A" on drawing.

5.

Remove only 3 counter sunk screws from valve cover (CL-85). Lift off valve cover (CL-85), two levers (CL-99), two

springs (CL-80) and gasket (CL-93).

6.

Remove four round head screws marked "B" on drawing.

7.

Remove assembly of valves, casting and filter sleeve.

8.

Loosen gland nuts on each valve stem.

11