TM 9-4910-726-14&P

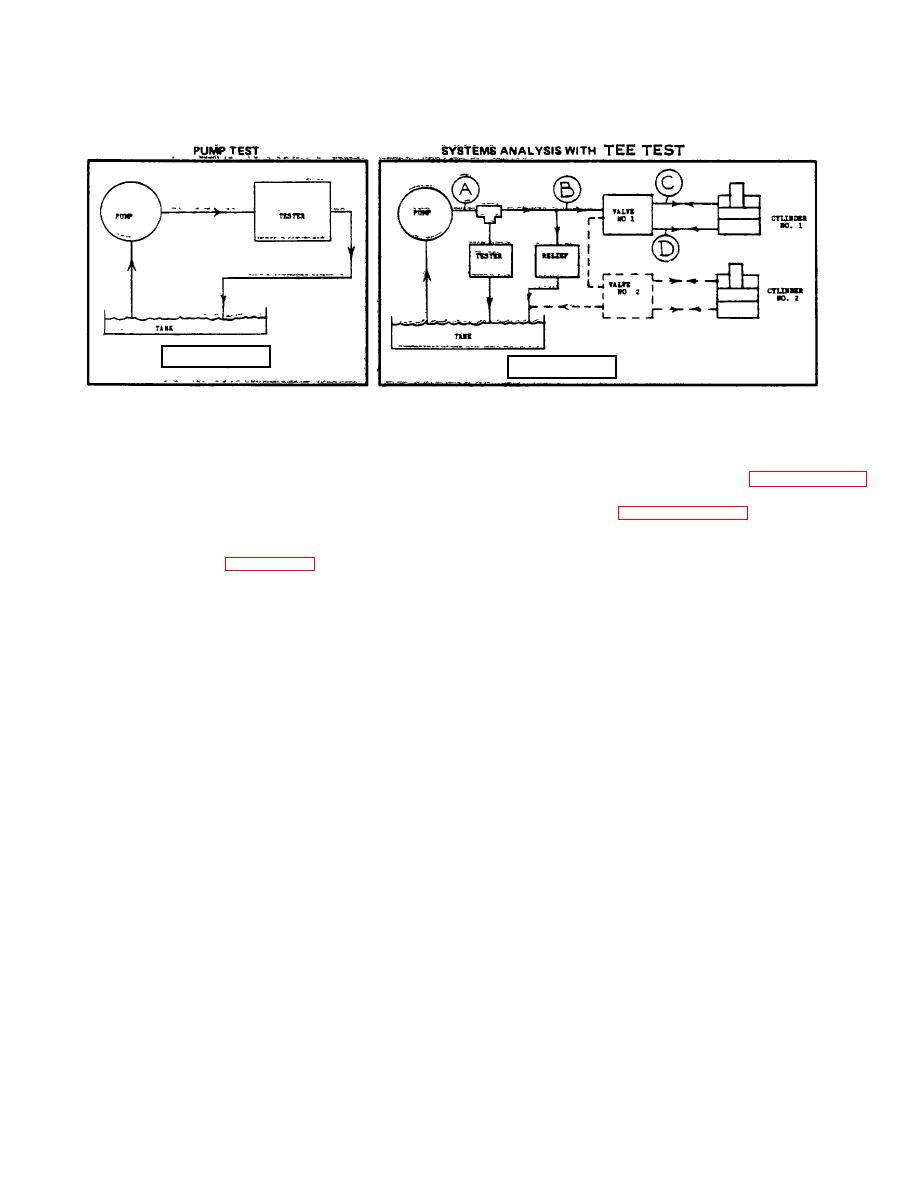

DRAWING 5.

DRAWING 6.

13. RAD THE GPM ON THE TESTER AT- OPERATING

16. REPEAT SAME AS IN 15 CLOSING VALVE 1 AND

PSI. CORRELATE THESE READIGS WTH PUMP

OPEN 2.

TEST STEP 9. IF THERE IS A LOSS IN GPM

OVER THE TESTER, THERE IS LEAKAGE,

17. IN THIS SYSTEM IF READINS IN PARAGRAPH 15

SLIPPAGE

OR

A

MALFUNCTIONING

AND 16 VARY AND ARE LESS THAN THE

COMPONENT IN THE SYSTEM.

READINS IN PARAGRAPH 14, OIL IS BEING

LOST IN EITHER THE VALVES OR CYLINDER.

14. CHECK THE RELIEF VALVE.

BLOCK LINE AS IN DRAWING 6, BLOCK B OR BY

18. ANALYZE THESE RESULTS AND DETERMINE IF

CLOSNG THE VALVES. DEPRESS THE TESTER

BLOCKS AND TEST SHOULD BE MADE AT

LOAD LEVER UNTIL THE RATED PRESSURE OF

POINTS C AND D.

THE RELIEF VALVE IS AHIEVED. WHEN THE

RELIEF VALVE OPENS, A SUDDEN DROP IN

19. THE CONSIDERATION IN ALL ANALYSIS IS THAT

GRM AND PSI WILL BE NOTED ON TEH TESTER

IF AT ANY POINT IN TEST THERE IS A LOSS OF

INSTRUMENTS.

GPM SHOWN ON THE TESTER AT OPERATING

RPM, TEMPERATURE AND PSI, THE OIL IS

LEAKING PAST ONE OF TME COMPONENTS

NOTE THE PSI AT WHICH THE RELIEF OPENS

RECEIVING FLOW AND PRESSURE.

AND

COMPARE

WITH

SYSTEM

SPECIFICATIONS. CORRECT RELIEF SETTING

20.

BY -ORATING WITH THE TEE TO TESTER

IF NECESSARY.

SHIFTING VALVES, DEAD ENDING CYLINDERS

AND BLOCKING LINES, A HYDRAULIC SYSTEM

CAN BE SEGMENTED AND EXAMINED.

15.

REMOVE BLOCK B WITH CONTROL VALVE 1

OPEN AND 2 CLOSED FULLY EXTENDED, THE

CYLINDER AND READ GPM AND PSI -AT

THIS TYPE OF ANALYSIS WILL LOCATE FAULTY

OPERATING TEMPERATURE AND RPM.

COMPONENTS IN PLACE ON THE SYSTEM.

4