TM9-4935-481-14-1

C3

Table 3-10. DMS-D Maintenance Calibration-Continued

Table 3-10. DMS-D Maintenance Calibration-Continued

STEP

UNIT

PROCEDURE

CORRECTIVE ACTION

STEP

UNIT

PROCEDURE

CORRECTIVE ACTION

NOTE

WARNING

Corrective action for steps for this procedure will be

accomplished by referring to the DMS-D performance test

Use extreme care when removing the front panel to

prevent injury to personnel or damage to equipment.

parentheses after each section sub-title or the DMS-D sche-

Place the aisle maintenance bench (see TM-02819D-15

matics. Location diagrams for test points and potentiometers

or TM-06895A-15) in front of the DMS-D, and use it

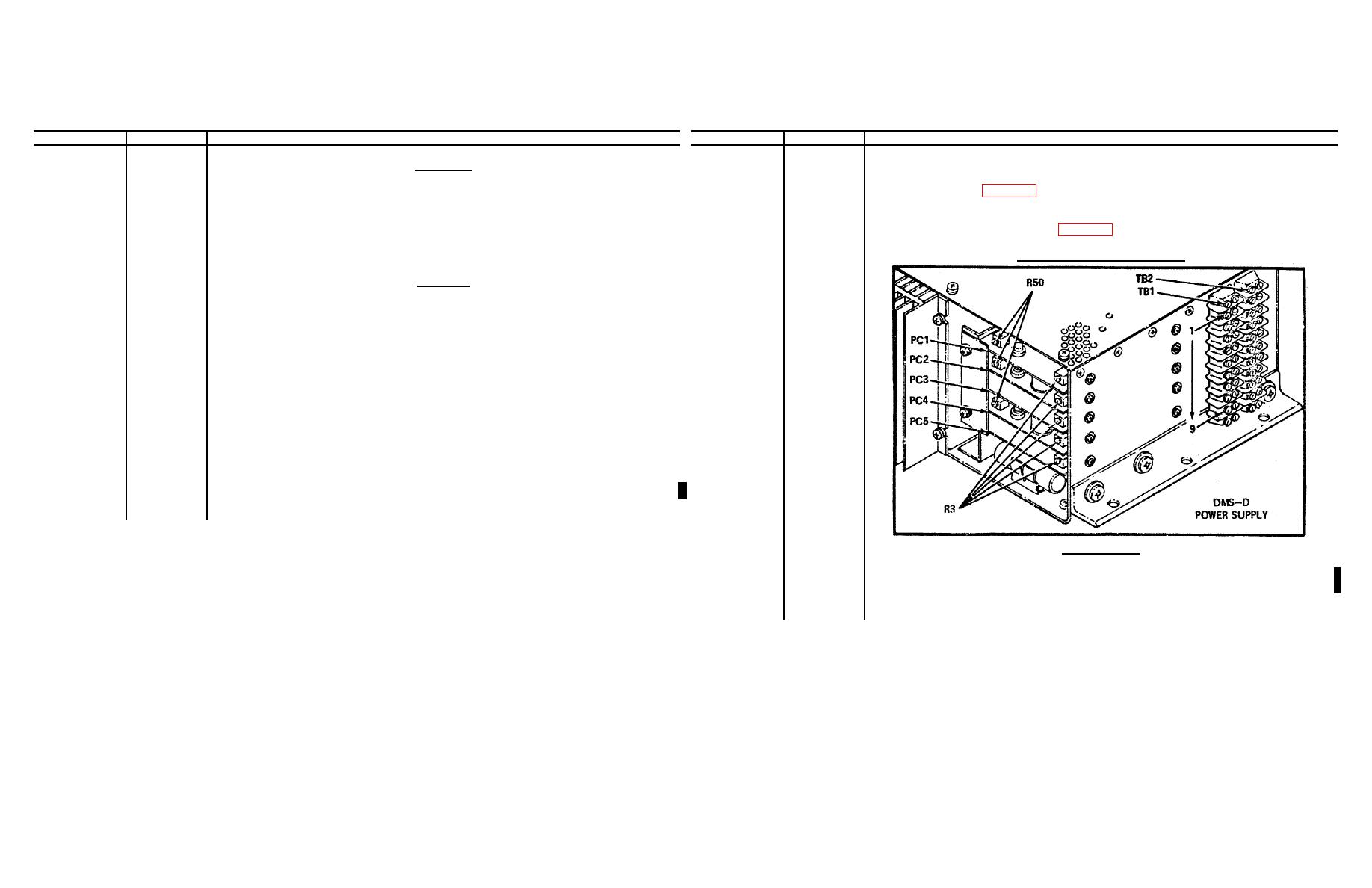

can be found in figure 3-35 immediately following this

to support the front panel assembly when removed in

procedure.

the following steps

Power Supply Adjustments (1-14)

CAUTION

Insure the DMS-G is NOT cabled to the DMS-D.

NOTE

For this procedure, utilize 48" BNC - BNC cables

for the CT connections.

2

Remove the screws securing the front panel to the case and

remove the front panel assembly, rotating it approximately 90and

placing it on the aisle bench. Ensure that the cable harness

is not strained. Connect a GND between front panel and chassis.

NOTE

Ensure that all mechanical type dial adjustments on the

front panel are aligned at 000 at their fully ccw position

(see chapter 4 for adjustment procedure).

3

PP

DMS switch to ON.

4

MCP

DMM INPUT switch to DMM INPUT.

+5 VDC Supply

5

Monitor with the DMM pos probe at TB1-1.

6

PP

MAIN POWER switch to ON. Momentarily actuate Test Start switch.

TP

7

Adjust PC1-R50 several turns cw.

8

Adjust PC1-R3 fully cw.

3-60