f. Inspect all exposed cables

for kinks,

blower vent, and air vent covers. Use oil

strains, moisture, fungi, loose

terminals,

(PL special or OE-10).

and for frayed, cut, or damaged

insulation.

c. Lubricate all metal-to-metal moving

g. Tighten loose mounting

hardware.

parts.

Caution: More frequent lubrication may

be required for items listed above in ex-

cessively hot, humid, or dusty areas. Do

a. Clean and tighten the components,

not overlubricate.

racks, mountings, installations, cables,

d. Remove the shelter air filter and

and connectors.

soak it in cleaning compound, benzine, or

b. Inspect the components,. racks,

naphtha. Shake loose dirt from the air

mountings, installations, and exposed met-

filter, air-dry it, and replace it in its

al surfaces for rust, corrosion, and mois-

mounting.

ture.

c. Inspect the cables and wires for cuts,

breaks, fraying, deteriorations, kinks, and

trigger mechanism. If the extinguisher

strain.

has been used, or if there are any signs of

d. Inspect for looseness of accessible

leakage, request that it be recharged by

items, such as component switches, circuit

appropriate personnel.

breaker switches, signal and ac cable as-

semblies, and glowlamps.

e. Clean the air fi1ter, nameplates,

meters, and clock.

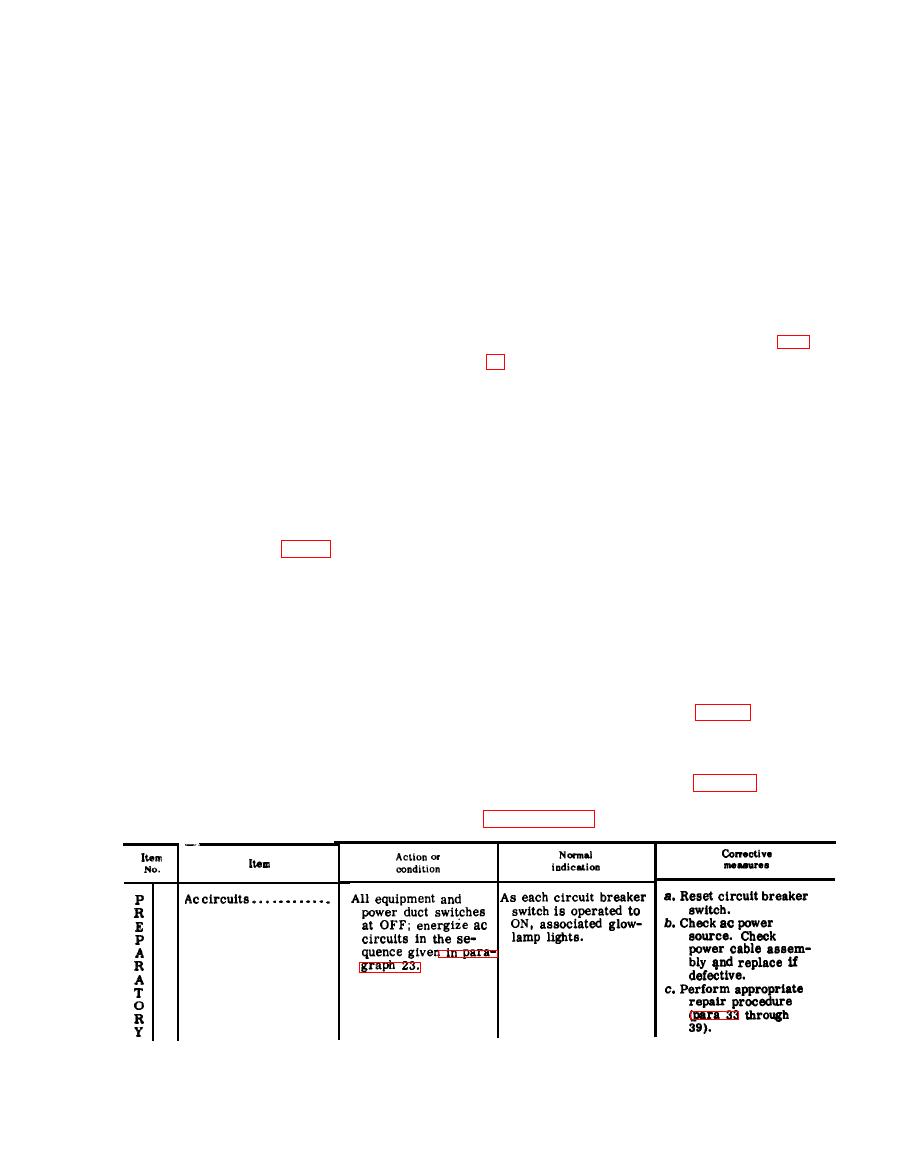

The equipment performance checklist is

f. Inspect meters and clock for damaged

used to systematically check the AN/MSC-

glass and cases.

31. Only first echelon maintenance correc-

tive measures are given in the Corrective

h. Inspect the shelter for support, in-

measures column. If the corrective meas-

stallation, rust, corrosion, and moisture.

ures given do not correct the fault, re-

quest higher echelon maintenance. When

blower vents, and air filter intake for

using the checklist, start at the beginning

cracks, leaks, damaged gaskets, dirt, and

and follow each step consecutively. If the

grease.

trouble is suspected in a particular area,

j. Check for normal operation.

start checking at that point and continue

the steps sequentially. Refer to the power

schematic-wiring diagram (fig. 37) when

brication

checking the S-183/MSC-31 ac circuits.

When a fault or trouble is located in a

a. Lubricate locks and l a t c h es. Use

major component item, refer to the appli-

Grease, Graphite, Aircraft MIL-G-7187

cable technical manual (appx I). First

(GGA) .

echelon repair procedures are given in

b. Lubricate the hinges on the shelter

door and on the entrance boxes, exhaust