TM 55-1925-283-12&P

OPERATOR AND UNIT MAINTENANCE

FUEL FILTER/WATER SEPARATOR (FUEL TRANSFER SYSTEM) FOR

INLAND AND COASTAL LARGE TUG (LT)

THEORY OF OPERATION

GENERAL

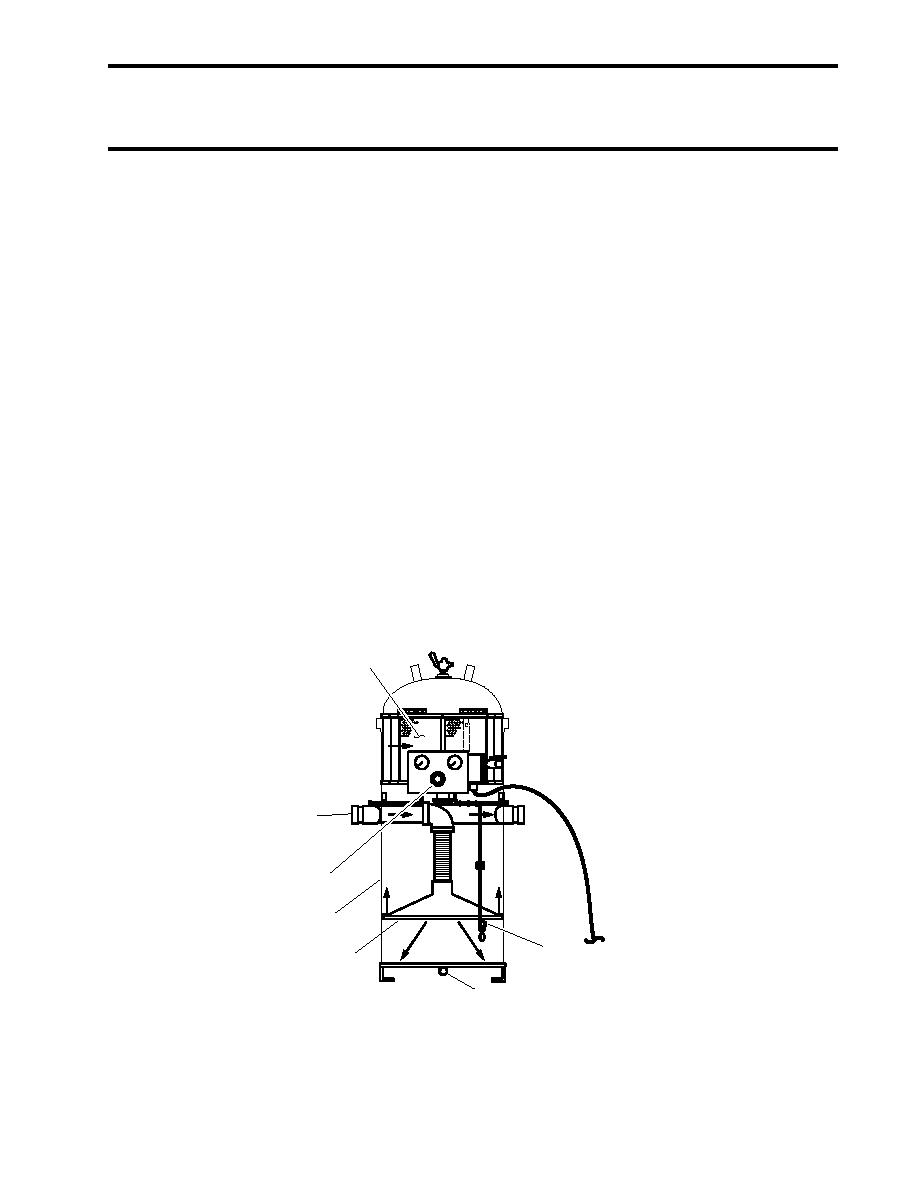

The fuel filter/water separator removes particulates and water from fuel entering the fuel transfer pumps. These

contaminants are removed from the fuel by centrifugal separation and by filtration. These processes are ex-

plained in depth in the paragraphs below.

The fuel filter water separator also gives an audible/visual alarm to alert the operator when the water level in the

unit exceeds safe operating limits. The operating theory for this alarm is discussed in the final paragraph of this

work package.

CENTRIFUGAL SEPARATION

Water and large particulates are removed from the fuel by centrifugal separation. In this process, fuel enters the

fuel filter/water separator assembly (figure 1, item 1) through the inlet fitting (figure 1, item 2). The incoming fuel

is directed through a set of stationary vanes in the turbine assembly (figure 1, item 3). These stationary vanes

cause the fuel to spin as it enters the area below the turbine assembly. As the fuel spins, the water and large

particulates (heavier than the fuel), are forced to the outside of the fuel filter/water separator assembly. The water

and large particulates strike the sides of the fuel filter/water separator assembly and fall to the bottom of the tank.

A drain fitting (figure 1, item 4) is provided to permit removal of the water and large particulates.

The fuel, now free of the water and large particulates, is drawn upward to pass through the filter elements prior to

exiting the fuel filter/water separator. This filtration process is explained in the following paragraph.

5

2

7

1

6

3

4

Figure 1. Fuel Filter/Water Separator Operating Principles

0003 00-1