TM 55-1925-286-13&P

0018 00

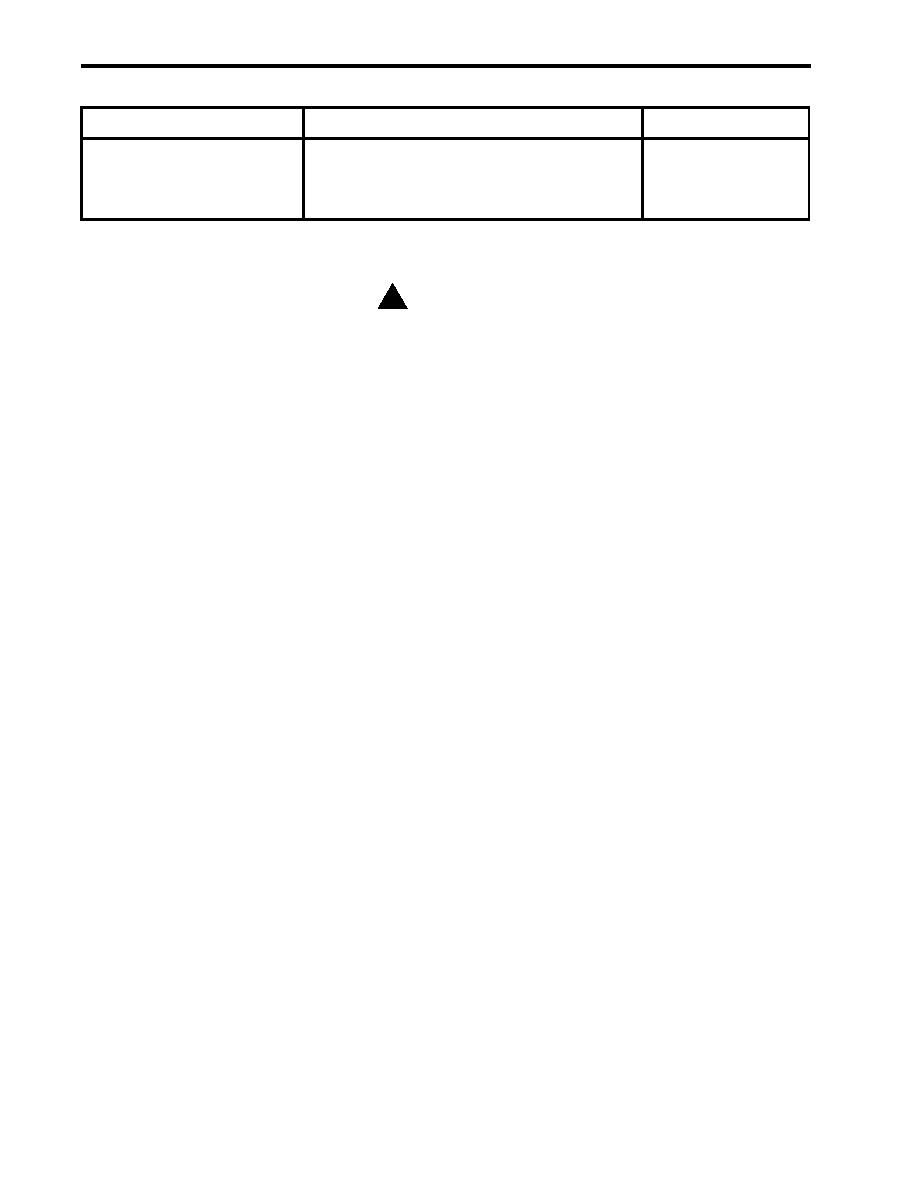

Table 1. Compressor Lubricants

Ambient Temperature

SAE Viscosity

NSN

32-80 F (0-27 C)

SAE 20W

60-104 F (16 to 40 C)

SAE 30W

9150-01-158- 2881

FLUSH THE CRANKCASE

! CAUTION

Crankcase flushing should only be performed if an incorrect lubricant was installed in

the crankcase. Serious damage to the compressor can result from failure to closely

follow the flushing procedure.

1. Perform the Change Oil and Filter procedure in this work package, ensuring that the crankcase is refilled

with the proper lubricant as shown in table 1.

2. Remove the lockouts and tagouts, and operate the air compressor for 15 to 20 minutes.

3. Set to OFF, lock out, and tag out AIR COMPRESSOR NO. 1 and AIR COMPRESSOR NO. 2 circuit

breakers.

4. Change the oil and filter again as described in the Change Oil and Filter paragraph of this work package,

ensuring that the crankcase is refilled with the proper lubricant.

5. Perform the Follow-On Service procedure at the end of this work package.

REPLACE AIR FILTER

1. Remove the wing nut (figure 1, item 4) and the air filter top cover (figure 1, item 5).

2. Remove the air filter element (figure 1, item 6).

3. Position the new air filter element (figure 1, item 6) on the compressor.

4. Secure the air filter element (figure 1, item 6) to the compressor with the top cover (figure 1, item 5) and wing

nut (figure 1, item 4).

5. Perform the Follow-On Service procedure at the end of this work package.

TORQUE PULLEY CLAMP SCREWS

1. Remove the three lower screws (figure 1, item 7) and one upper screw (figure 1, item 8) that secure the belt

guard (figure 1, item 9). Remove the belt guard.

2. Use a torque wrench to tighten both pulley clamp screws (figure 3, item 1) to a torque of 90 lb-ft (122 Nm).

3. Install the belt guard (figure 1, item 9) and secure it with the three lower screws (figure 1, item 7) and one

upper screw (figure 1, item 8).

4. Perform the Follow-On-Service procedure at the end of this work package.

0018 00-4