TM 9-1375-213-12

Section 1. OPERATING PROCEDURES

2-1. General

Inspect M2 Crimper jaws for elongated, oval or

This section contains operating procedures for the

egg-shaped opening, when they're closed.

two types of firing systems in use (electric and

Inspect crimping jaws and cutting jaws for dull

nonelectric) and methods for priming charges.

or jagged edges. If jaws of blasting cap crimper

Also included are operating procedures for

form an elongated, oval or egg-shaped opening

detonators, explosive destructors, fuse igniters,

when closed, a misfire can occur by squeezing

and firing devices which may be used for special

the cap too tightly around the fuse; likewise, if

applications in the field.

the jaws have dull or jagged cutting edge.

Assemble a nonelectric system as instructed in

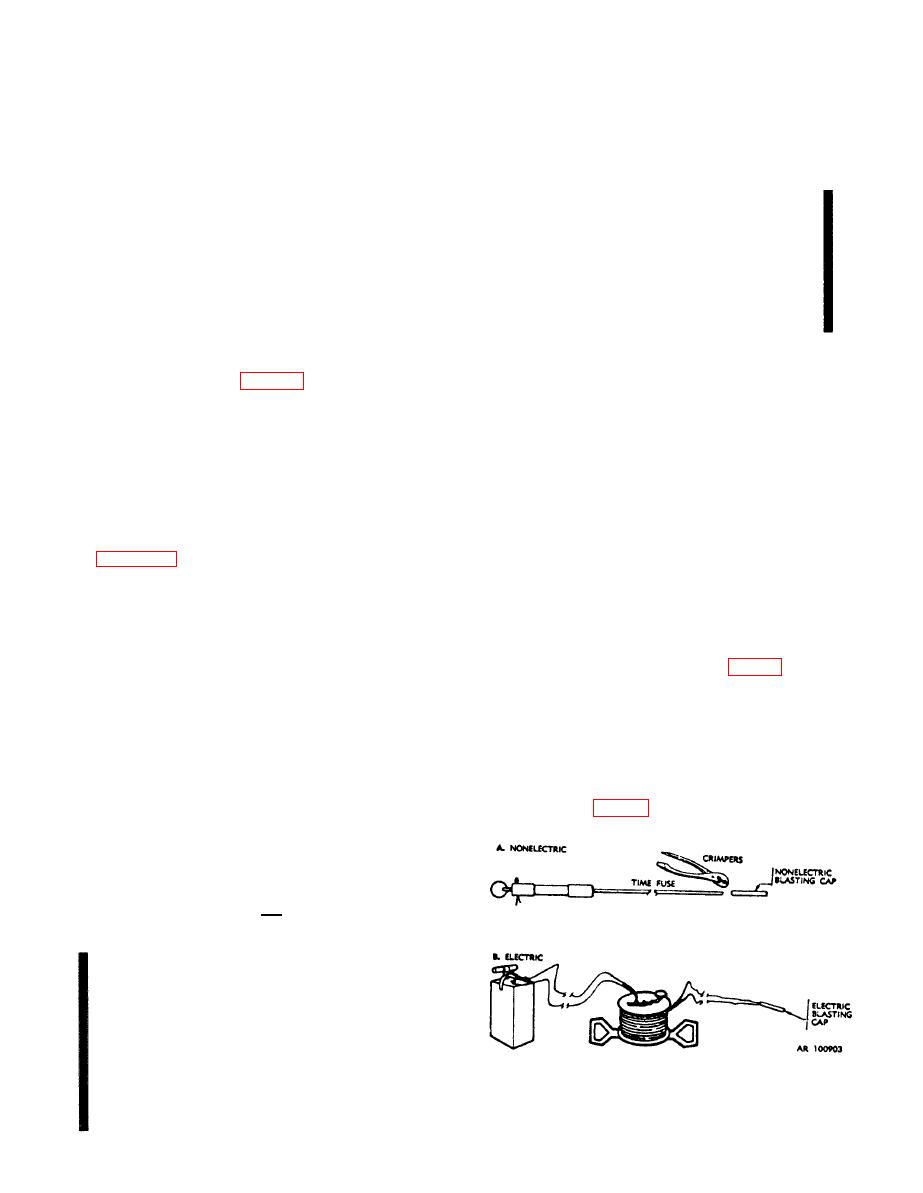

A nonelectric system (fig. 2-1) is one in which an

a through 1 below.

explosive charge is prepared for detonation by

means of a nonelectric blasting cap. The basic

WARNING

materials consist of a nonelectric blasting cap,

which provides the shock adequate to detonate the

A rough jadded cut fuse inserted into a blasting

explosive, the time blasting fuse, which transmits

cap can cause a misfire. If the rough cut is due

the flame that fires the blasting cap, and a means

to an unserviceable crimper M2, requisition a

of igniting the time fuse. If more than one charge

serviceable crimper. If a serviceable crimper is

must be detonated simultaneously, the nonelectric

not available, use a sharp knife to cut the fuse.

system must be combined with detonating cord

To assure that the fuse is cut square when using

the knife, cut fuse against a solid surface such

firing.

as wood.

NOTE

a. Using crimper M2, cut and discard a 6-inch

length from free end of time blasting fuse to

A nonelectric priming system will normally be

prevent a misfire caused by exposed powder

assembled in the field at the demolition site.

absorbing moisture from the air (A, fig. 2-2)

Under some circumstances, if desired, some

subassembling may be done in advance in order to

b. Cut off a three-foot length of time blasting

save time or to avoid exposing components to rain.

fuse to check burning rate.

etc. When it is desired to have the assemblies

prepared more than a few hours in advance, use

c. Ignite fuse with a fuse igniter (see para ((1),

blasting cap sealant to waterproof the fusecap

(2) and (3) below), if available, or cut a slit near

joint. This sealant will protect the fusecap joint for

one end of fuse, insert a match head into split,

an indefinite period of time. The assembly will be

and light match (fig. 2-3).

t r e a t e d as a blasting cap for storage and

transportation (e.g., keep separate from other

explosives). When using waterproof time blasting

fuse igniter M60, it may be assembled to the

blasting fuse and cap prior to insertion into the cap

well of the explosive, I F the safety pin is still

instilled.

Inspect M2 crimpers to ensure the stop is at least

1/16-inch high. Inspect the nut on M-2 crimper to

ensure it is well staked to bolt to prevent removal

of nut thus loosening the jaws. If the nut is not

staked in the bolt that holds the crimper together,

the crimper can come apart while being used. Too

short a bolt can cause the same thing to happen.

Turn in defective crimpers for replacement or

tighten nut and restake it using a hammer and

chisel, to assure it cannot come loose

Change 12 2 - 1