TM 9-2320-285-10

2-14.

OPERATING PROCEDURES (Continued)

h. Lowering Cab to Normal Operating Position (continued).

(6)

If velocity fuse has set, proceed as follows:

(a)

Rotate control valve clockwise against stop and move pump handle up and down to raise cab slightly.

(b)

Follow steps (4) thru (6) above to lower cab.

2-15.

PREPARATION FOR MOVEMENT

a. General. Follow these procedures to protect the tractor when you ship it from one site to another.

b. Preservation and Packaging.

(1)

Do your before (B), weekly (W), and monthly (M) PMCS (refer to Section II of this chapter). Especially, check

coolant system to be sure it is filled to the proper level with a clean solution of ethylene glycol compound

conforming to NIL-A-46153A. Refer to Table 2-2 below and check that coolant has the proper mixture for the

required amount of antifreeze protection.

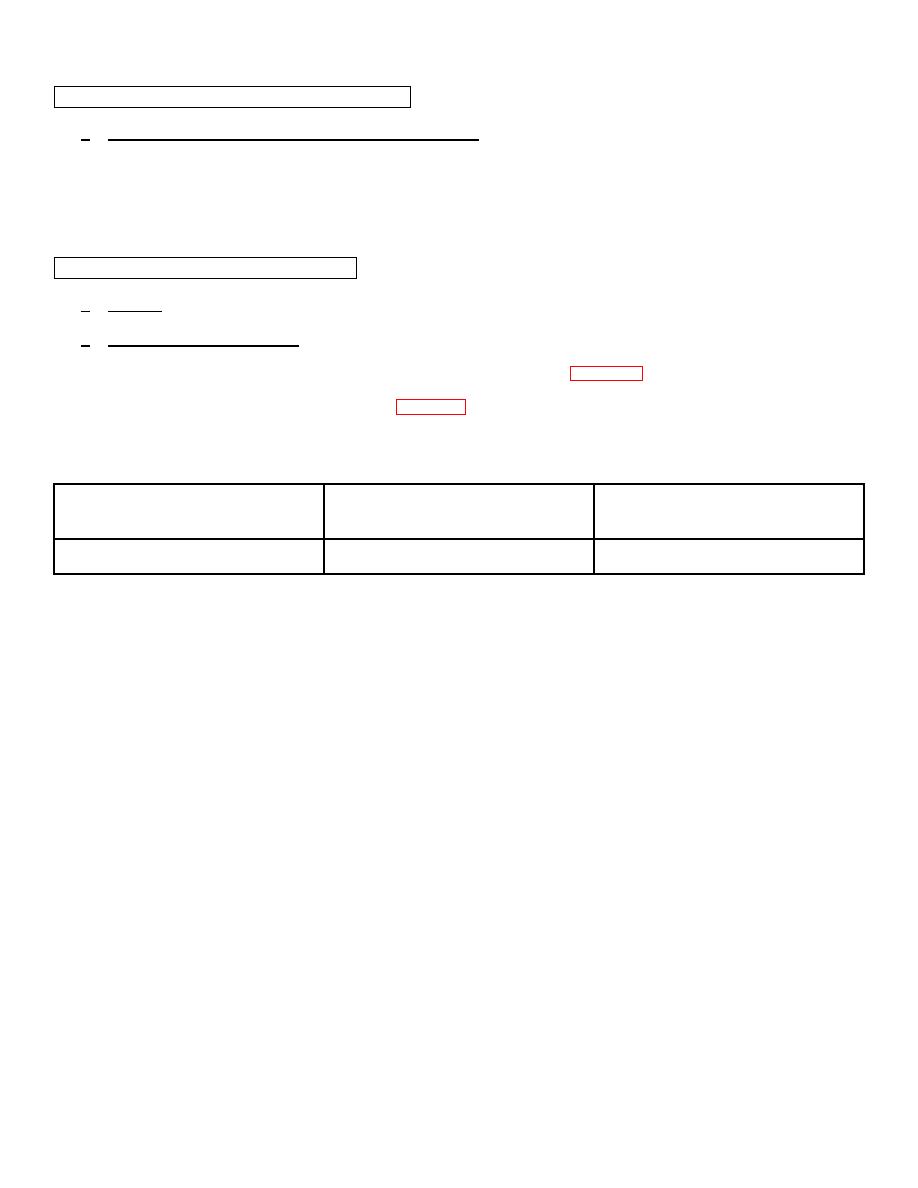

Table 2-2. Antifreeze Specifications

Lowest Estimated

Antifreeze

Temperature In

Antifreeze Mixture

Specification

Geographic Area

Percent by Volume

Requirement

+20 to -30 degrees F

50% Ethylene Glycol & 50% Water

MIL-A-46153A

-30 to -55 degrees F

60% Ethylene Glycol & 40% Water

MIL-A-46153A

(2) Refer to current lubrication order and lubricate tractor. Operate engine until lubricant has been circulated

throughout system. Do not drain oil from crankcase.

(3) Hydraulic System. Retract the pistons as far as linkage will permit and secure in retracted position. Coat

exposed portions of the hydraulic piston ram shafts with type P-6 preservative (CL) conforming to MIL-C-11796, class 3.

Grease, automotive and artillery, conforming to MIL-G-10924 may be used if type P-6 preservative is unavailable. Wrap

the coated shafts with type 1, class 2, grade A, greaseproof barrier material conforming to NIL-B-121.

(4) Exterior Surfaces. Coat exposed machined ferrous metal surfaces, such as fifth wheel plate, with type P-6

preservative (CL) conforming to MIL-C-11796, class 3. GAA grease may be substituted if type P-6 preservative is not

available.

(5) Openings. Seal openings that will permit direct entry of water with pressure-sensitive tape conforming to

PPP-T-60, type IV. Bridge large openings with waterproof barrier material conforming to PPP-B-1055, and secure the

edges of the barrier material to adjacent surfaces with pressure-sensitive tape.

2-47