TM9-2330-207-14

b. Cleaning.

(1) Remove all buildup of dirt, grease and foreign materiel from wheel using a stiff bristle or wire brush.

(2) Remove all foreign materiel from inside of tire. Clean bead area with a stiff bristle brush.

c. Inspection.

(1) Wheels.

(a) Inspect wheels for cracks, dents and warps.

(b) Inspect wheels for deformed lug bolt holes.

(c) Inspect wheels for rust, corrosion and marred paint.

(2) Tires.

(a) Inspect tires for cracks, holes and signs of separation.

(b) Inspect tires for uneven wear.

(c) Inspect tires and tubes for deterioration.

d. Repair. Tires and tubes are to be repaired in accordance with TM 9-2610-200-20. No repair is author-

ized at the organizational level for the rims.

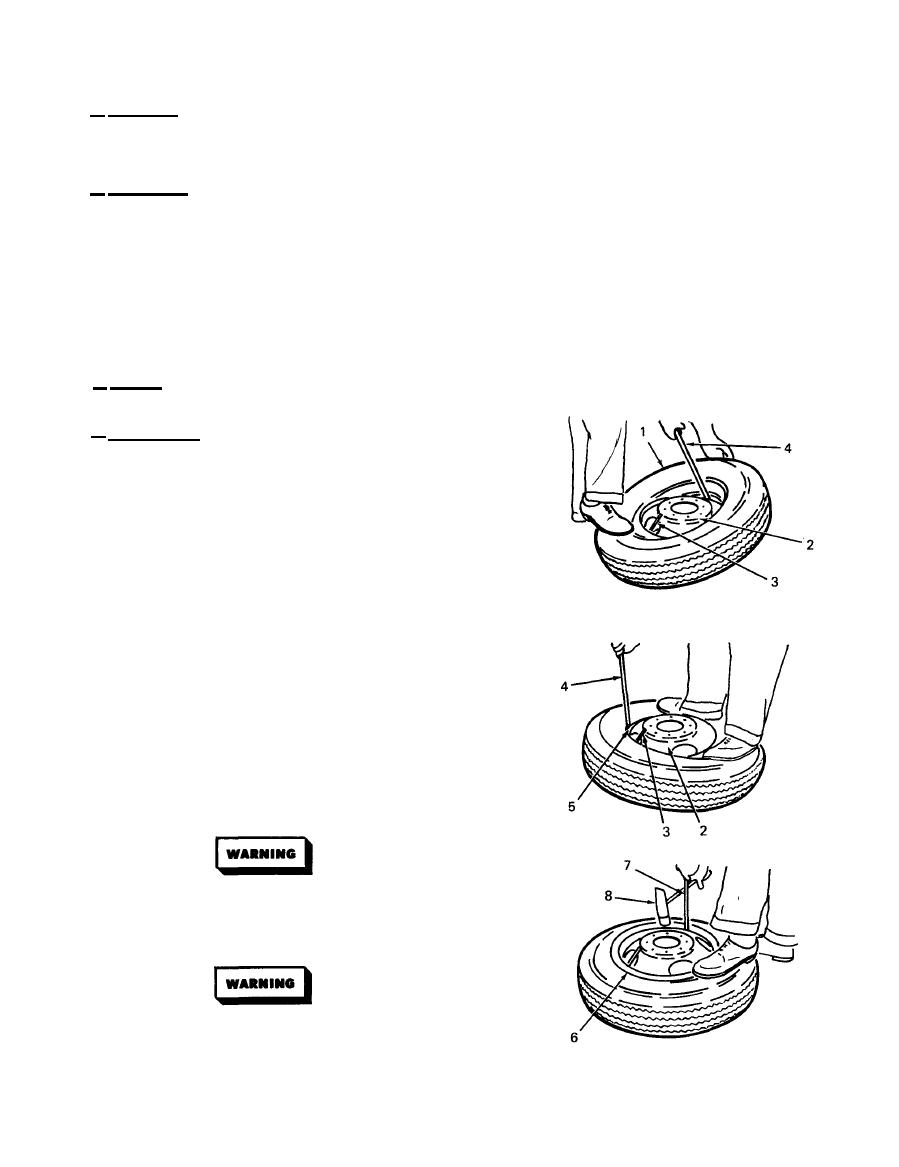

e. I n s t a l l a t i o n

(1) Place tire (1) on rim (2) and install bottom

bead onto rim.

(2) Install tube so that valve (3) is in line with

valve hole.

(3) Insert valve (3) into valve hole. Valve must

point to ring side of wheel.

(4) Force bead down into well of rim near

valve (3).

Using a tire tool (4), work tire bead over

(5)

rim (2).

Start at point opposite valve (3) and

(6)

press bead (5) over rim (2).

Using tire tool (4), mount remainder of

(7)

bead (5) over rim (2). Use extreme care

so as not to damage tube.

Place half of ring (6) in rim gutter.

(8)

Using rim tool (7), pull ring (6) outward,

(9)

then strike ring (6) with a lead, brass or

composition type mallet (8) to seat ring (6).

Before inflating tires, check to be sure that

tire is seated on rim, the tube is not pinched,

and rim is not damaged.

(10) Install tire valve.

Use a safety cage or a clip-on type tire valve

to inflate the tire. Do not stand on ring side

TA 233608

of tire when inflating.

Figure 4-26. Tire mounting

(11) Inflate tires to 60 psi.