TM 9-2330-251-14&P

4-8. PMCS PROCEDURES (Con't).

-

(3) Item To Be Inspected. Lists system and common names of items that are to be inspected.

(4) Procedures. Tells you how to do the required check or service.

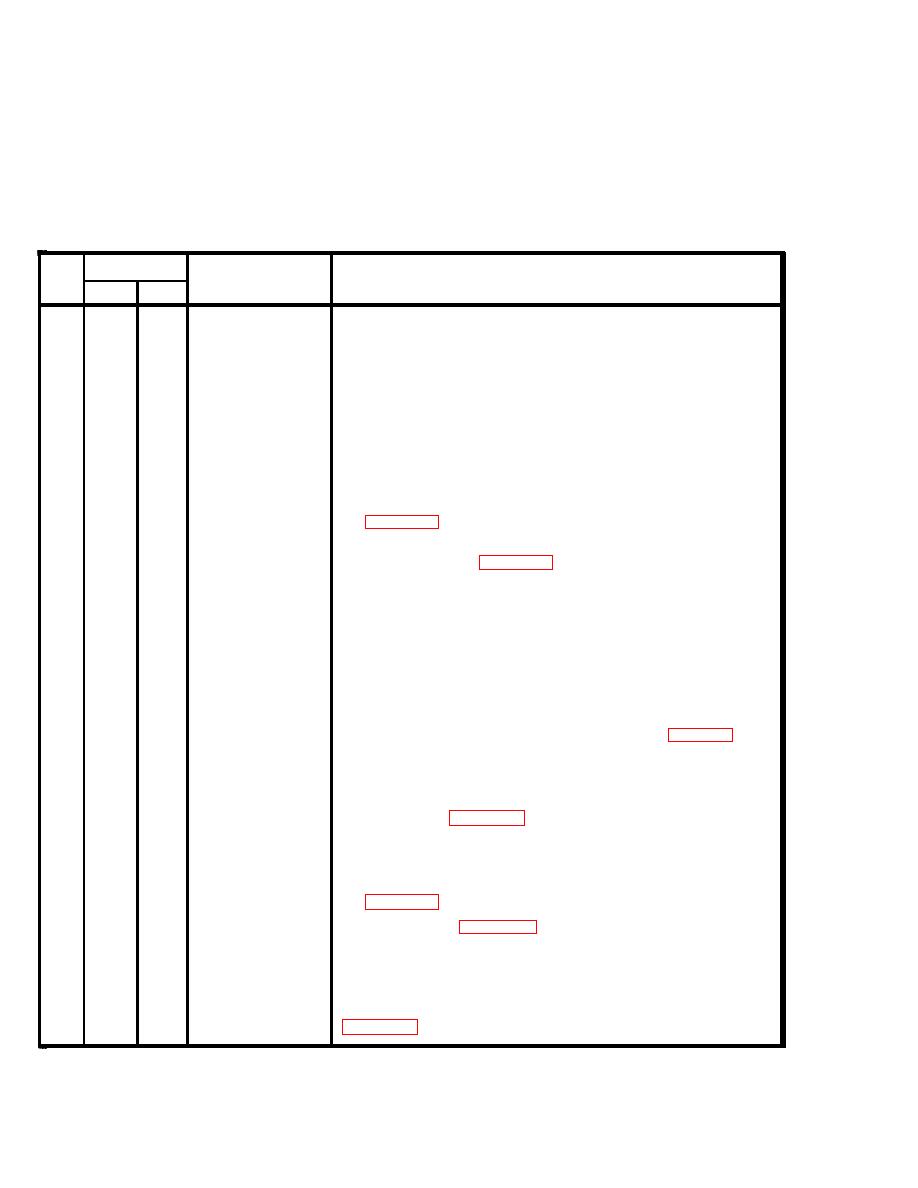

Table 4-1. Organizational Preventive Maintenance Checks and Services (PMCS).

S - Semiannual

A - Annual

ITEM

INTERVAL

ITEM TO BE

INSPECTED

PROCEDURES

NO.

s

A

NOTE

Perform operator/crew PMCS prior to or in conjunction

with organizational PMCS.

1

BODY AND

FENDERS

Look for cracks and dents. Check that fenders are secured to

q

body .

2

SUSPENSION

a. Check suspension for bent or cracked parts, loose mounting,

q

and worn bushings. Replace any damaged component

(para 4-43 or 4-44).

q

b. Check shock absorbers for damage or leaks, Replace if dam-

aged or leaking (para 4-45).

3

FRAME

q

Look for cracks, bent members, or broken welds. Notify direct

support maintenance of any damage found.

4

WHEELS AND

TIRES

q

a. Check serviceability of tires in accordance with TM 9-2610-

200-24.

q

b. Tighten wheel nuts to 85 Ib. -ft. (115 Nm) (para 3-7).

5

WHEEL

q

Remove hubs and wheel bearings. Clean, inspect, and pack

wheel bearings (para 4-36 or 4-37).

BRAKE

6

ASSEMBLIES

a. Clean, inspect, and replace internal brake parts as required

q

(para 4-30 or 4-31).

q

b. Adjust brakes (para 4-28 or 4-29).

7

MASTER

CYLINDER

(M416A1)

q

Check fluid level in master cylinder. Fill to in. (13 mm) from top

4-4