TM 9-2330-251-14&P

Section IX. WHEELS, HUBS, AND BRAKEDRUMS MAINTENANCE

Page

Number

Paragraph Title

Hub, Wheel Bearing, and Brakedrum Maintenance (M416) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hub, Wheel Bearing, and Brakedrum Maintenance (M416A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tires and Tubes Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-36. HUB, WHEEL BEARING, AND BRAKEDRUM MAINTENANCE (M416).

This Task Covers:

Assembly

d.

a.

Removal

Installation

Disassembly

b.

Wheel Bearing Adjustment

c.

Cleaning and Inspection

Initial Setup:

Materials/Parts:

Equipment Conditions:

Sealing compound (Item 3, Appendix E)

Wheel removed (para 3-7),

q

q

q Grease (Item 5, Appendix E)

Tools/Test Equipment:

q Dry cleaning solvent (Item 10, Appendix E)

q One oil seal

General mechanic's tool kit

q Floor jack

References:

q Jackstand

q TM

9-214

q Spindle-nut socket wrench

REMOVAL

a.

WARNING

DO NOT handle brakeshoes, brakedrums, or

other brake components unless area has

been properly cleaned. There may be asbes-

tos dust on these components which can be

dangerous if you touch it or breathe it. Wear

an approved filter mask and gloves. Never

use compressed air or a dry brush to clean

brake components. Dust may be removed us-

ing an industrial-type vacuum cleaner. Clean

dust or mud away from brake components

with water and a wet, soft brush or cloth. Fail-

ure to follow this warning may result in seri-

ous illness or death to personnel.

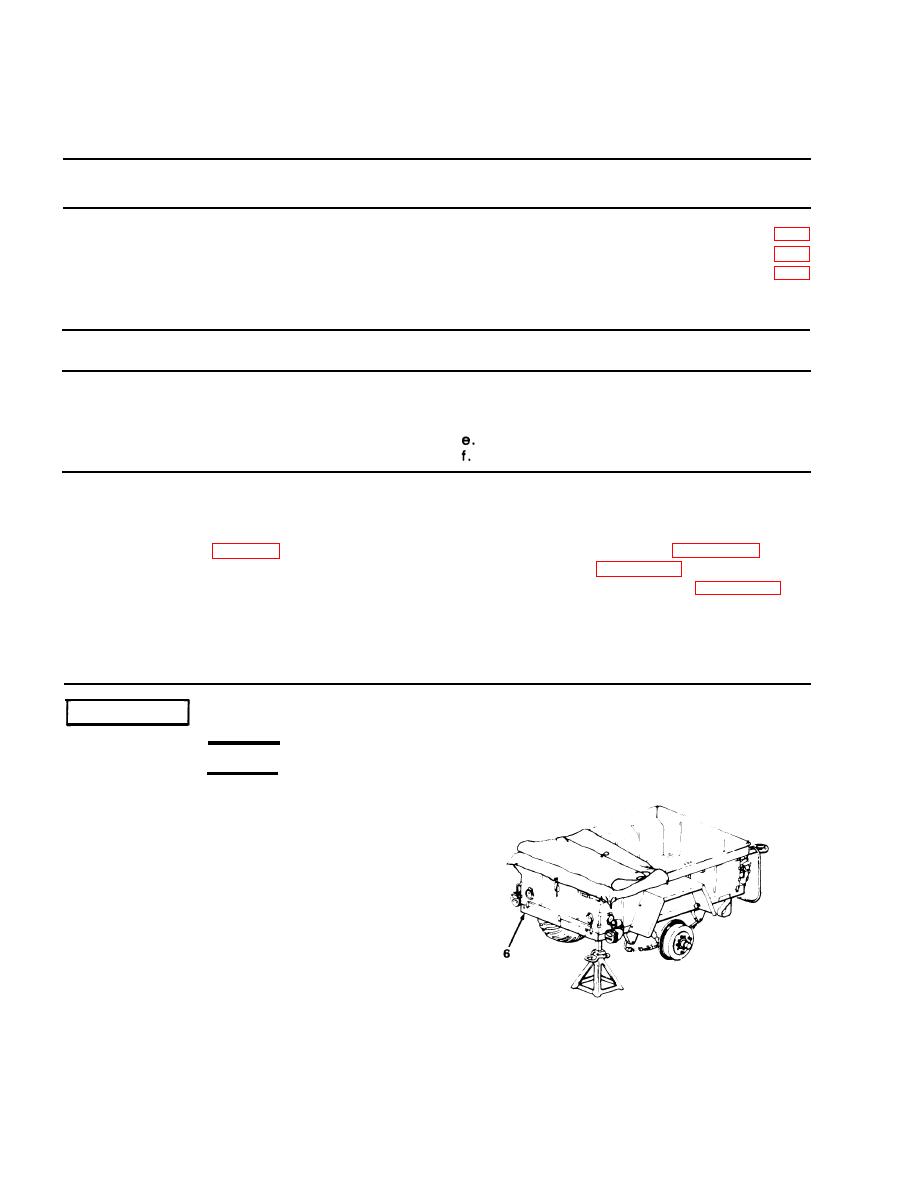

1.

Position a suitable jackstand at rear corner of

chassis (6). Lower and remove floor jack.

TA503941

4-58