TM 9-2330-271-14&P

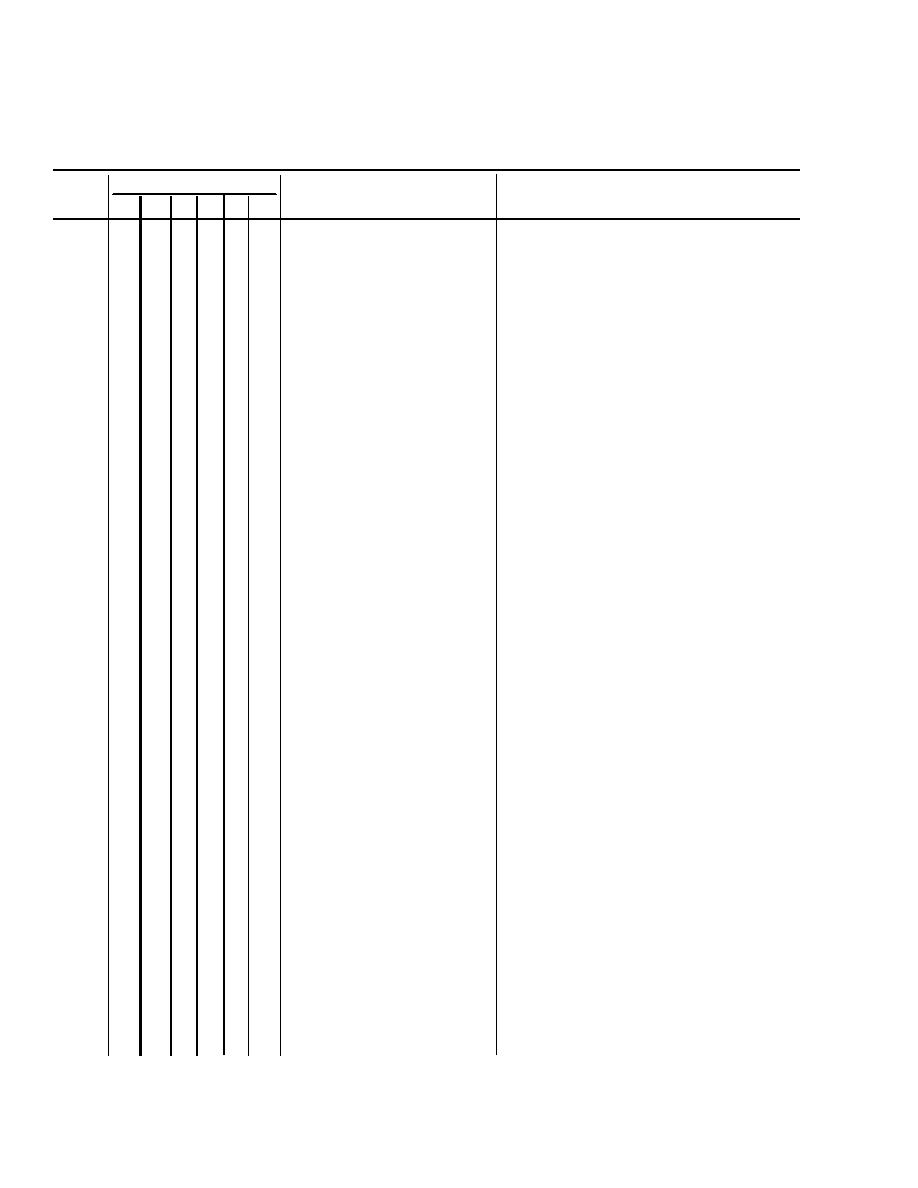

Table 4-1. Organizational Preventive Maintenance Checks and Services - Continued

Q=Quarterly

A=Annually

H=Hours

S=Semiannually

B=Biennially

MI=Miles

ITEM

INTERVAL

Item To

NO

Q S A B H MI

Be Inspected

Procedures

LANDING GEAR

9

With semitrailer coupled to towing vehicle,

check operation of landing gear.

BODY

10

Inspect for loose or damaged hardware.

11

Visually inspect for Indications of rust.

BRAKES

12

During road operation, make several

stops, observe any side pull, noise,

chatter, or other unusual condition.

Apply semitrailer brakes only, verify that

brakes operate properly.

BRAKE DRUMS AND

HUBS

13

Following operation, cautiously feel

brake drums and hubs. An overheated

drum/hub may indicate an improperly

adjusted, defective, or dry wheel bearing

or dragging brake. An unusually

cool drum/hub may indicate an inoperative brake.

SPRINGS/SUSPENSION

14

Inspect springs suspension and torque

rods for loose or broken components.

15

Tighten spring U-bolts, leaf clips, all

assemblies, and mounting bolts

WHEEL BEARINGS

16

Clean wheel bearings and repack.

KINGPIN, FIFTH WHEEL

17

Inspect kingpin and upper fifth wheel

plate for damage. Tighten all mounting

hardware Lubricate as necessary.

AIR SUSPENSION SYSTEM

18

First

Inspect for loose nuts, bolts, and air

1000

connections Tighten as necessary.

&

3000

19

First

Check air springs for equal inflated

1000

firmness

&

3000

20

First

Check ride height dimension

1000

&

3000

21

Check suspension system for broken or

abnormally worn parts

22

Block up rear of semitrailer until tires

clear ground and suspension is fully

extended Insure that air springs fully

deflate

4-9