TM 9-2330-271-14&P

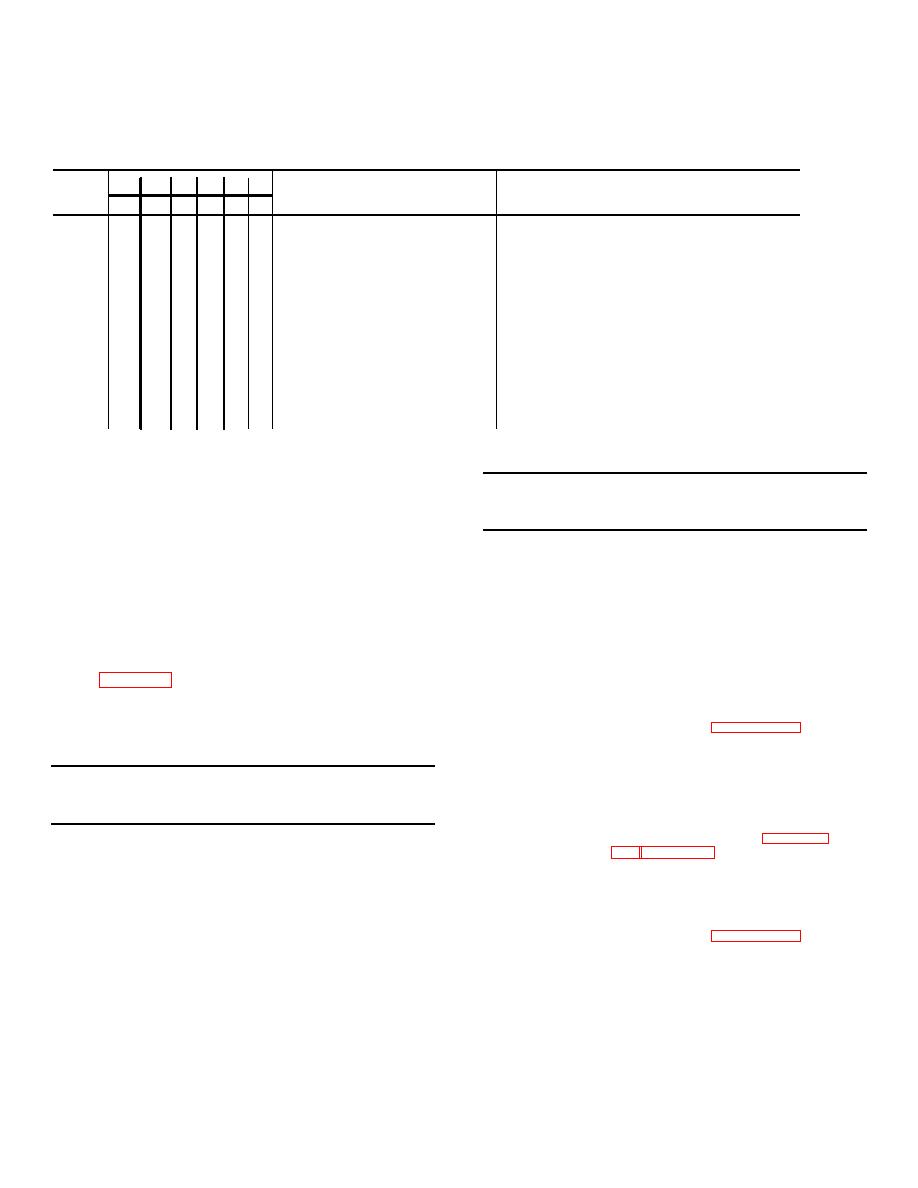

Table 4-1. Organizational Preventive Maintenance Checks and Services - Continued

Q=Quarterly

A=Annually

H=Hours

S=Semiannually

B=Biennially

MI=Miles

ITEM

INTERVAL

Item To

NO

Q S A B H MI

Be Inspected

Procedures

23

With rear of semitrailer blocked as in

item 22, inspect air spring for wear at

connection points. Check shock absorbers

for oil leakage or worn rubber

bushings. Check for wear resulting

from insufficient clearance around air

springs, shock absorbers, and tires.

AIR MOUNTED FIFTH

WHEEL KINGPIN

24

Check shock absorbers for oil leakage or

worn rubber bushings.

25

Inspect hinge bushings for wear.

Section VI. TROUBLESHOOTING

Table 4-2. Troubleshooting - Continued

4-13.

Scope

a. This

section

contains

troubleshooting

MALFUNCTION

information for locating and correcting most of the

TEST OR INSPECTION

operative troubles which may develop in the semitrailer.

CORRECTIVE ACTION

Each malfunction for an individual component, unit or

system is followed by a list of tests or inspections which

ELECTRICAL SYSTEMS - Continued

will help you to determine corrective actions to take. You

Step 4

Check to see that current is flowing from

towing vehicle.

should perform the tests/inspections and corrective

Check towing vehicle cables and circuit

actions in the order listed.

breakers.

b. This manual cannot list all malfunctions that

Step 5

Check wiring harness for short circuitl

may occur, nor all tests or inspections and corrective

Check cable for bare spots Repair if

necessary.

actions. If a malfunction is not listed or is not corrected

Step 6

Check light switch on towing vehicle.

by instead corrective actions, notify your supervisor.

Replace towing vehicle light switch if

c. Table 4-2 lists the common malfunctions which

defective.

you may find during the operation or maintenance of the

2.

ONE OR MORE 24-VOLT LAMPS WILL NOT LIGHT

semitrailer or its components.

Step 1

Inspect for burned out lamp.

Replace defective lamp (paragraphs 3-9

through 3-14).

Table 4-2. Troubleshooting

Step 2

Inspect for dirty or corroded cable contacts in

sleeves or lamp sockets.

MALFUNCTION

Remove lamps and clean contacts

TEST OR INSPECTION

Step 3

Check for broken or loose connections

Tighten, repair, or replace as necessary

CORRECTIVE ACTION

Step 4

Check to see if light assembly Is defective

Replace defective light assembly (paragraphs

ELECTRICAL SYSTEM

1.

ALL 24-VOLT LIGHTS FAIL TO OPERATE

Step 5

Inspect intervehicular cable for dirty or cor-

Step 1. Inspect intervehicular cable for proper con-

roded terminals

nection in all steps, check for loose ground

Clean receptacle and plug

connection

3.

DIM OR FLICKERING 24-VOLT LIGHTS

Connect cable properly. Tighten ground

Step 1

Clean to see If lamp is defective

Step 2 Inspect for dirty or corroded terminals in

Replace defective lamp (paragraphs 3-9

intervehicular cable

through 3-14).

Clean terminals in plug and receptacle

Step 2

Inspect for poor or loose ground connections

Step 3 Check to see that light switch on towing

Clean ground cable terminal and tighten

vehicle is in desired position

connections.

Place towing vehicle light switch in proper

Step 3

Inspect for loose, dirty, or corroded

mode of operation.

terminals

Clean and tighten terminals

4-10