TM 9-2330-294-14

assembly and axle lift assembly do not touch brake

at top of axle lift assembly and axle lift assembly do

not touch brake at top of axle lift assembly. If either

does touch bracket, re-inflate air suspension bag by

moving control valve lever to FULL LOAD position

and recheck free axial play in rod and readjust if

necessary. After axle lift assembly has been ad-

justed, tighten rod jam nut to 250 to 275 lb ft torque.

a. Test.

(1) Ensure air system is fully pressurized and air

shutoff valves are open (para 2-7c).

(2) Set suspension air control valve to "FULL

LOAD" position (para 2-7). Observe that the two

front axles are raised until tires are approximately

three inches off ground. If axles fail to raise,

troubleshoot suspension air system in accordance

with table 4-4. If axles raise properly proceed to (3).

(3) Set suspension air control valve to "NO

LOAD" position (para 2-7). Observe that the two

rear axles are raised until tires are approximately

three inches off ground. If either axle fails to raise,

troubleshoot suspension air system in accordance

with table 4-4.

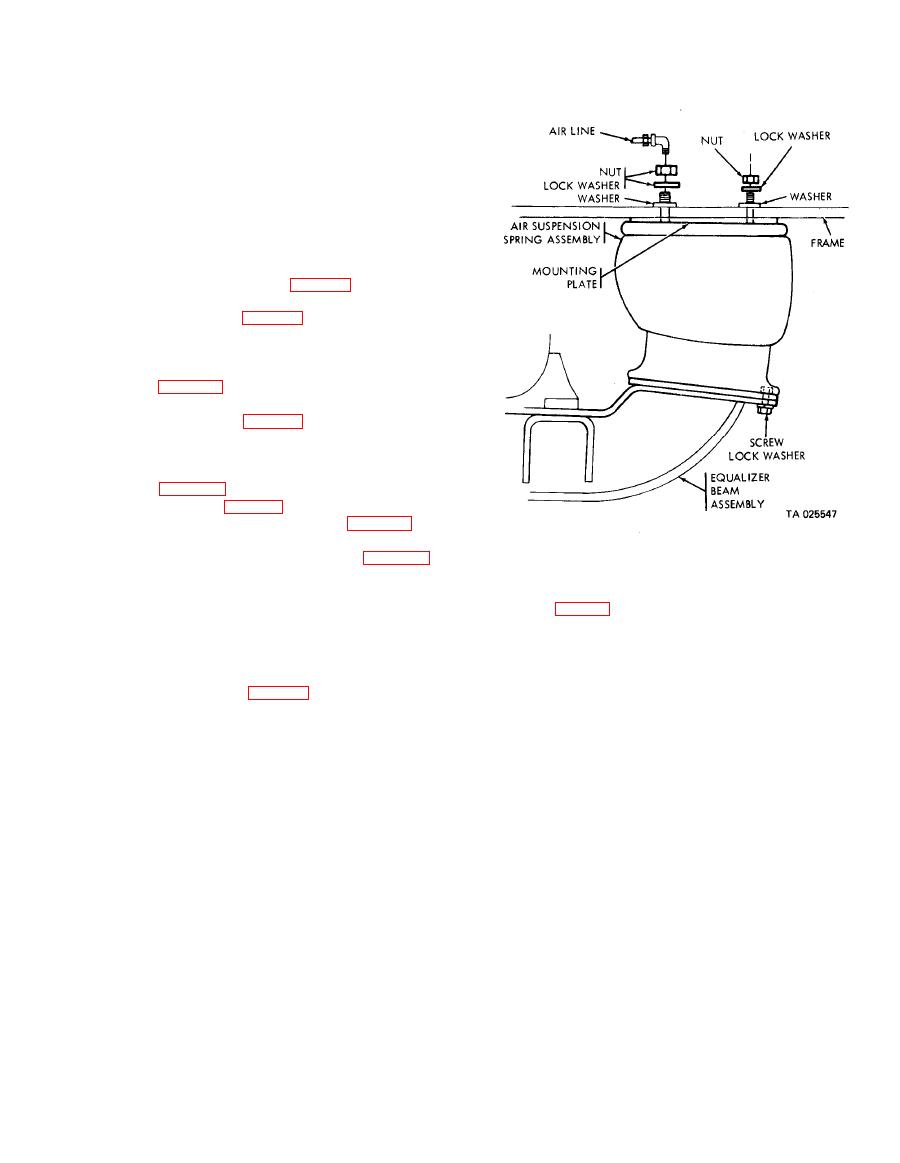

(1) Depressurize air system (para 4-38).

(2) If axle 8 air springs are to be removed,

remove air spring protection plate (para 4-61).

(3) Remove two cap screws and lockwashers

(Semitrailer 1 through 200)

securing bottom of air spring to equalizer beam.

(4) Disconnect air line from top of air spring.

(5) Remove two nuts, lockwashers, and washers

a. Removal.

securing top of air spring to frame.

(1) Detach spring from eye bolt on frame.

(6) Remove air spring and plate by compressing

Remove cap screw, lock washer, nut, spacer and

air spring and pulling down from frame.

clamp spring to chain.

( 2 ) Remove chain from axle and snubber

install in reverse order of removal (b above). Tighten

assembly by removing two cotter pins and retaining

nuts securing air springs to frame to 55-75 lb ft.

pins.

Tighten cap screws securing air spring to equalizer

(3) Disassemble chain by removing two cotter

beam to 55-75 lb ft. Pressurize air system and test

pins and link pin retainer securing adapter at each

air springs in accordance with a above.

end of chain. Remove adapters.