TM 9-2330-356-14

(2) Testing Armature.

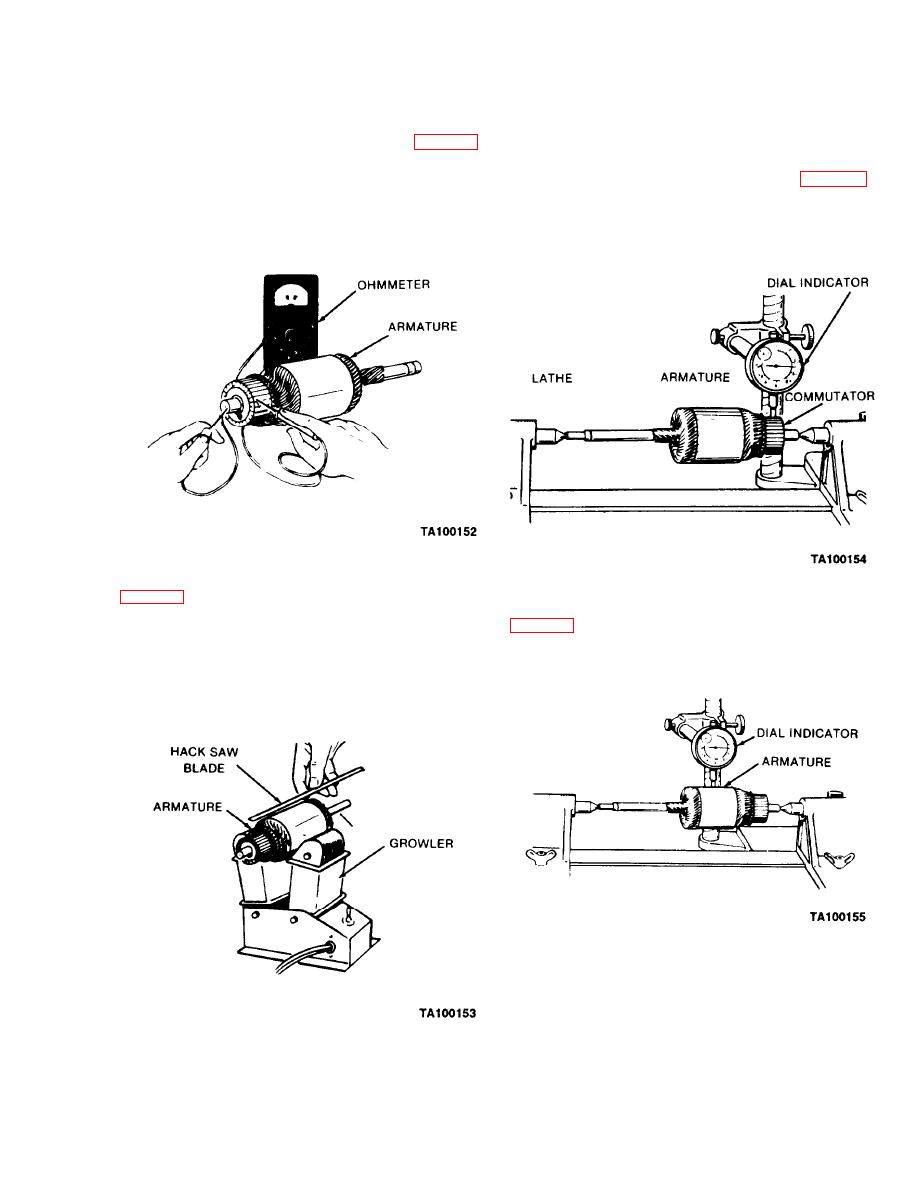

(c) Testing Amature for Open Coils. Test coils

for continuity with ohmmeter. A resistance reading

(a) Testing Armature for Grounds (Fig. 7-82).

indicates open coil.

Touch armature shaft and the end of each commutator bar

with a pair of ohmmeter leads. There should be no conti-

(d) Tessting Commutator Runout (Fig. 7-84).

nuity. If continuity is indicated between any commutator

Place armature in a test bench and test runout with a dial

bar and shaft, it indicates a grounded armature. Replace

indicator. When commutator runout exceeds 0.004-inch,

starter.

replace starter.

(b) Testing Armature for Shorted Coils

(e) Testing Armature Shafl Runout

With the armature in the growler, turn the growler on and

run a steel strip (such as a hacksaw blade) over the arma-

runout with a dial indicator. If the shaft is bent or worn,

ture surfaces. If a coil is shorted, the steel strip will be-

starter must be replaced. Runout should not exceed

come magnetized and vibrate. Rotate the armature

0.006-inch.

slightly and repeat the test. Do this for one complete revo-

lution of the armature. If the armature has a short, replace

starter.

(3) Testing Field Coils.

(a) Using a test lamp and probes, check the

field coils for grounding to the motor frame or open

circuit.