TM 9-2330-381-14

CAUTION

During this entire task, continually check that the top of the bearing seating tool

remains parallel to the platform. The bearing must be installed as level to the

platform as possible or damage to equipment may result.

3.

With bearing cone (1) level, and centered at bottom of spindle (2), slowly raise floor jack to push bearing onto

spindle.

4.

If platform starts to rise from movement of floor jack before bearing cone (1) is properly seated on spindle (2),

proceed as follows:

a. Place a block of wood on top of platform, centered over top of spindle (2).

b. Using a 10-pound sledge hammer, one person must proceed to strike wood block as second person raises floor

jack. Repeat as necessary until bearing cone (1) is properly seated on spindle (2).

c. Lower floor jack and remove bearing seating tool.

5-11.

DRUM TURNING

This task covers:

a. Inspection

b. Repair

INITIAL SETUP

Tools

Brake drum lathe, item 14, appx. B

Brake drum gage, item 14, appx. B

Equipment Condition

Hub and drum disassembled and separated (para. 4-50)

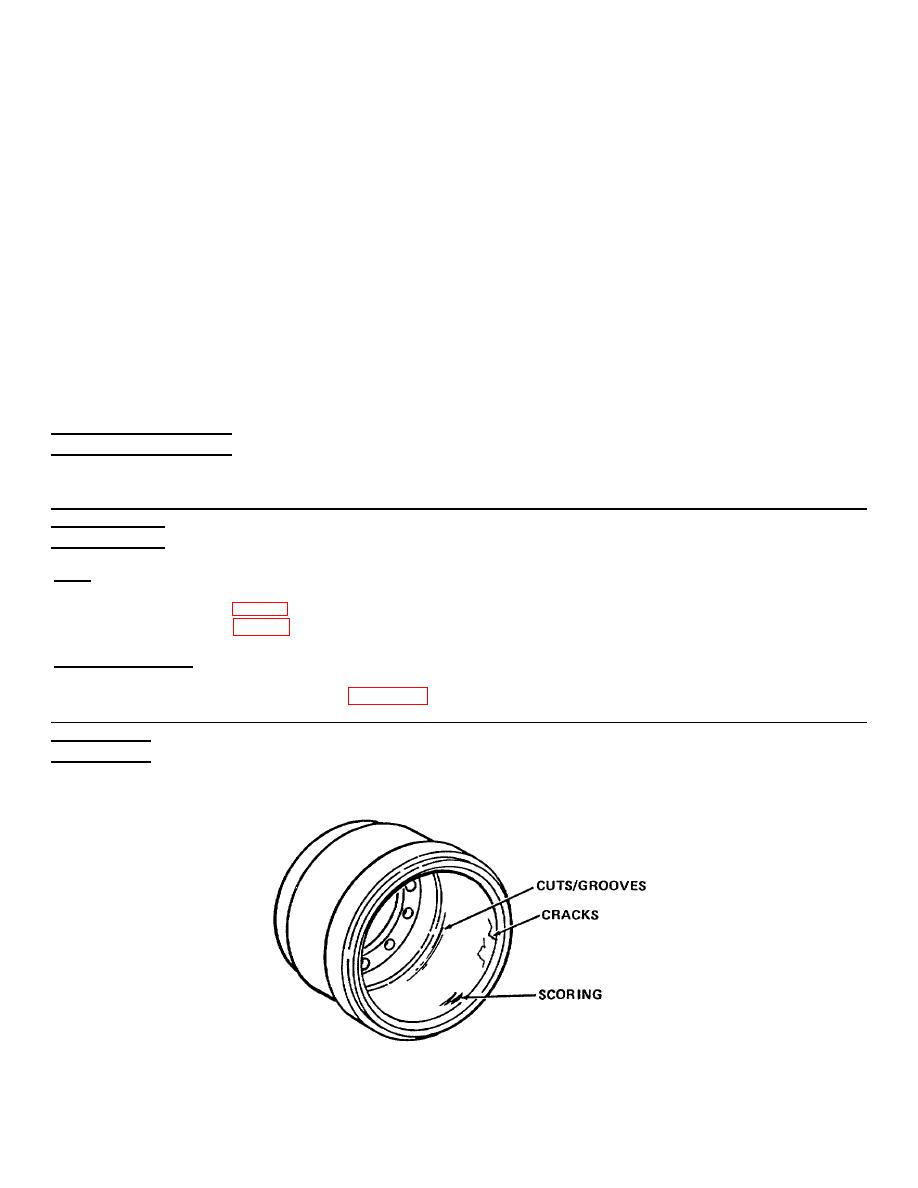

INSPECTION

1.

Inspect machined surface texture of drum for grooves, cuts, scoring, surface cracks, and out-of-roundness.

5-13