TM 9-2330-384-14&P

4-48. RIM ALINEMENT.

THIS TASK COVERS

a.

Rim Alinement Check

Rim Alinement

b.

INITIAL SETUP

Equipment Conditions:

Tools:

Ref Conditions

Tool kit, general mechanic's

Floor jack

Jackstand

Lug wrench

Torque wrench

a. RIM ALINEMENT CHECK

Place a suitable floor jack under axle in front of brake chamber and raise wheels clear of

(1)

ground. Support axle with a suitable jackstand.

Cage brake chamber spring (see paragraph 4-33).

(2)

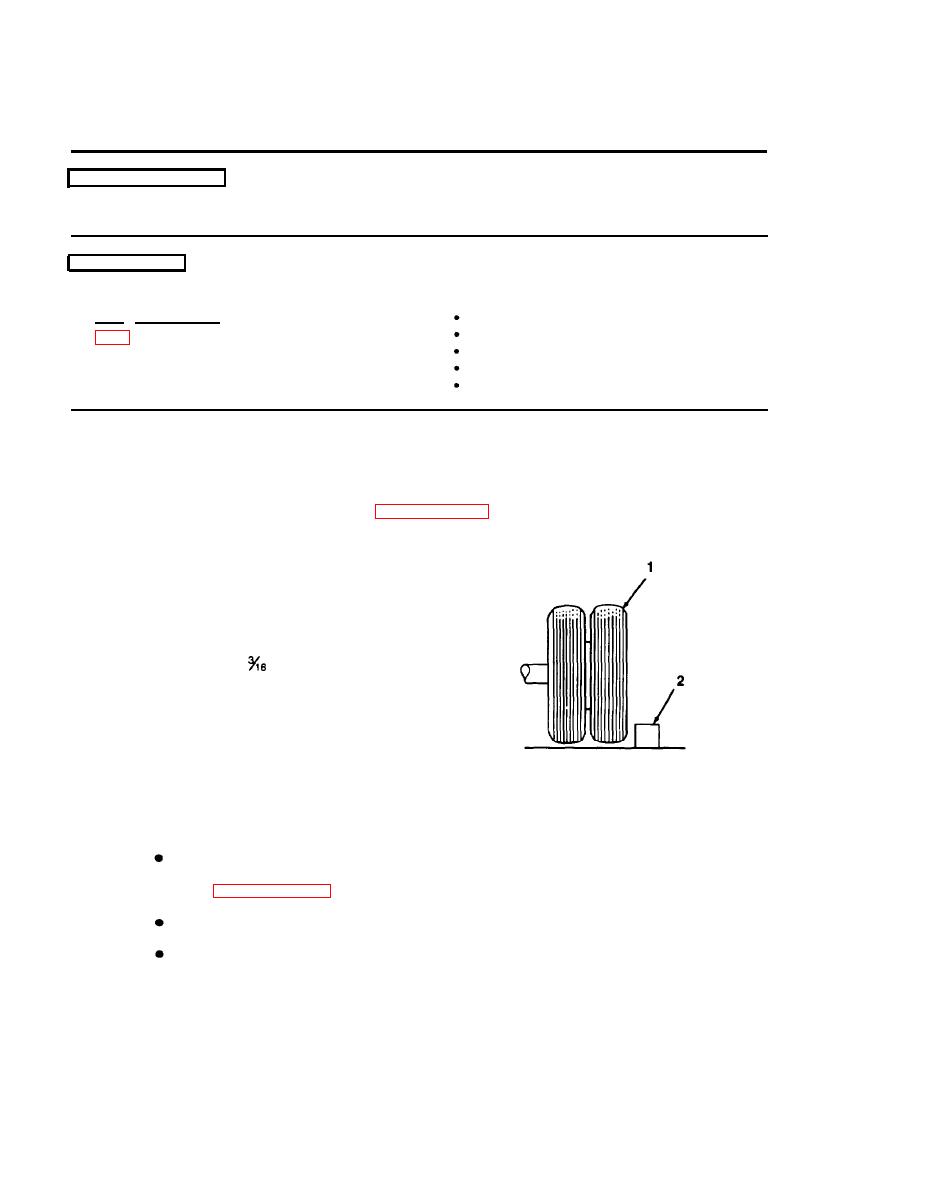

Place block of wood (2) or other

(3)

rectangular object on surface be-

side tire (1). Rotate wheels.

Note variation, if any, in space be-

(4)

tween block of wood (2) and tire

(1) as wheels are rotated. If vari-

in. (4.8 mm),

ation exceeds

perform RIM ALINEMENT (subpara-

graph b).

Remove jackstand and lower axle.

(5)

b. RIM ALINEMENT

NOTE

If rim alinement procedure does not correct misalinement, rim, wheel,

or drum may be damaged and must be removed for further inspection

(see paragraphs 4-45, 4-46, and 4-49).

Ensure that rim clamps (3) remain in proper position.

Optimum wheel nut torque is 250 lb.-ft. (339 Nm).

(1)

Loosen wheel nuts (4) where inward deviation is greatest and tighten on opposite side.

4-154