TM 9-2330-386-14&P

4-36 SLACK ADJUSTER ( CONT) .

b. Test.

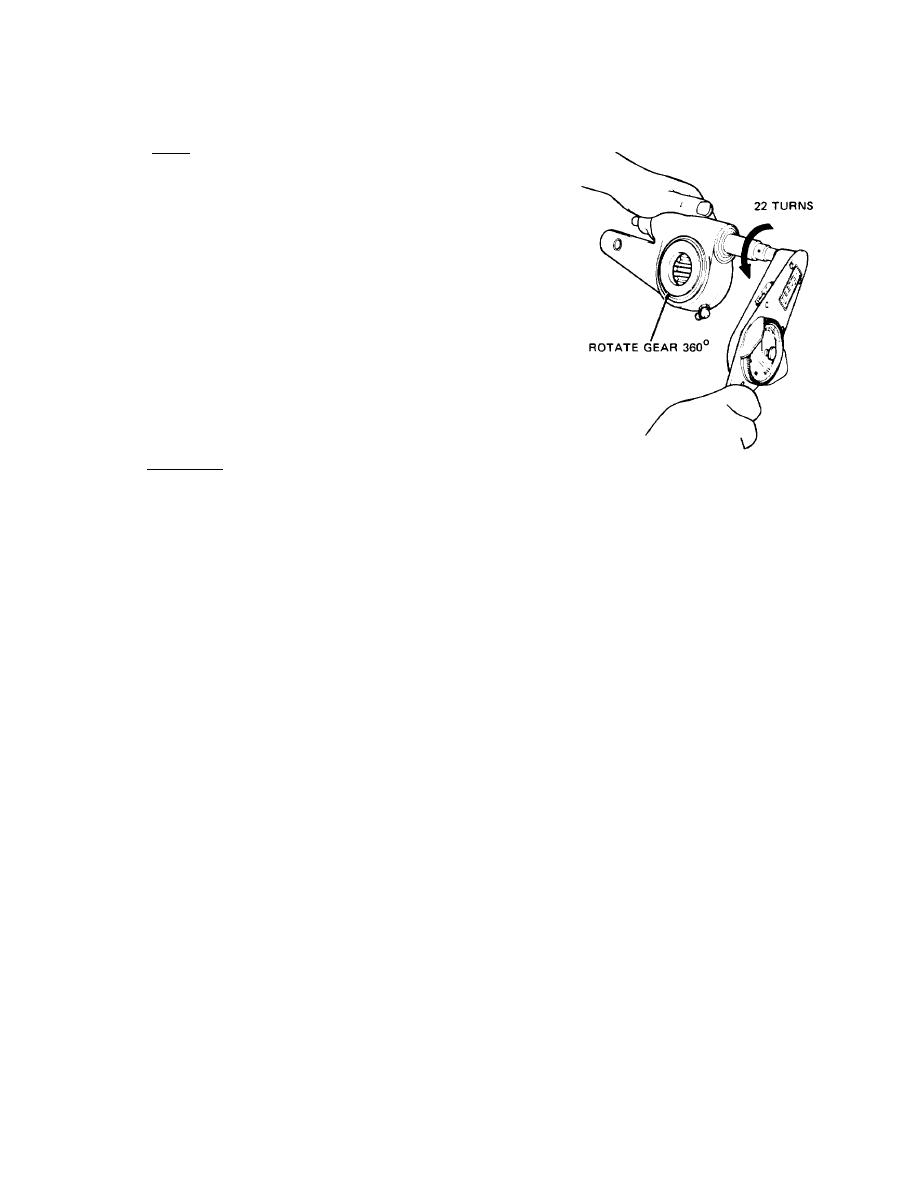

(1) Using lb-in torque wrench, turn

adjusting nut (16) in direction

s h o w n . Read torque indication

w h i l e you turn torque wrench 22

complete revolutions, to rotate

slack adjuster gear 360 degrees.

(2) If torque indication is 45 lb-in

o r less during the complete 360

degree rotation of slack adjuster

gear, the slack adjuster is okay.

(3) If torque indication is more than

45 lb-in, the slack adjuster is

defective. Replace slack adjuster.

c. I n s t a l l a t i o n

(1) push new collar (15) in clevis (14).

(2) Install clevis (14) with collar (15) on brake chamber push rod (18) at

position recorded during removal. Do not tighten the push rod jam

nut (19).

(3) Measure thread engagement between clevis (14) and push rod (18). If thread

engagement is less than 1/2 inch, turn collar (15) on push rod until

t h r e a d engagement is 1/2 inch minimum.

(4) Tighten jam nut (19) against collar (15) assembly to hold clevis in

correct position.

(5)

Install

lubrication

fitting

(13)

in

slack

adjuster.

(6) Apply clean GAA grease to camshaft (17) splines and splines on slack

adjuster (11) gear.

(7) Install spacer (12) and slack adjuster (11) on camshaft (17).

(8) Install washer (10) and retaining ring (9) on camshaft (17).

(a) Using thickness gage, measure clearance between washer (10) and

r e t a i n i n g r i n g ( 9 ) . C l e a r a n c e must not exceed 0.062 inch.

(b) If clearance is more than 0.062 inch, remove retaining ring (9) and

install additional washer(s) (10) until correct clearance is obtained.

4-71