TM9-2330-386-14&P

5-5 AXLES (CONT).

(1) Install two pads (8) with rounded edges on spring (10). Install end

cap (7).

(2) Install two U-bolts (6), four washers (5), and lock nuts (4). Do not

tighten lock nuts.

(3) Install four capscrews (3), washers (2), and lock nuts (1). Do not tighten

lock nuts.

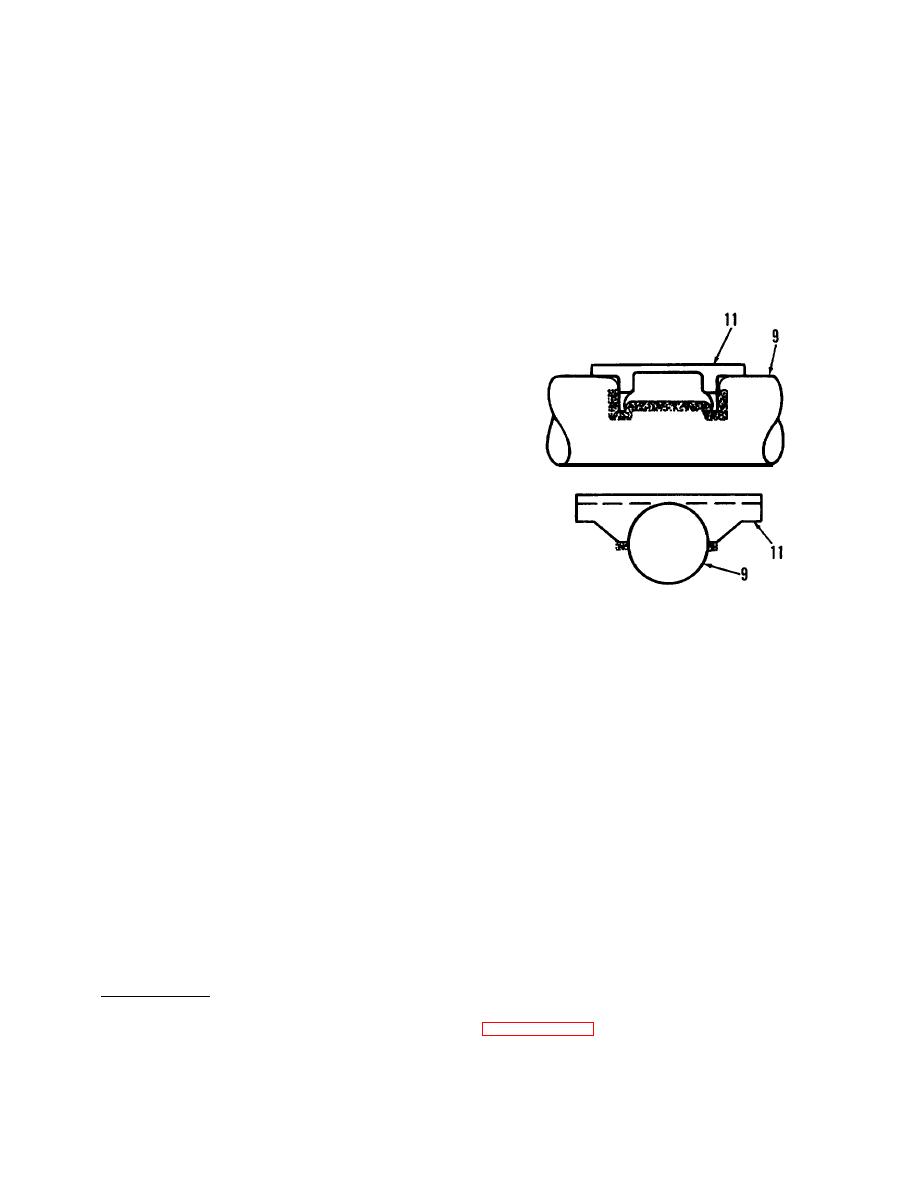

( 4 ) S p r i n g s e a t s ( 1 1 ) m u s t b e arranged so

that the center of the seat is at the

top of the axle (9) beam. The exact top

o f the axle beam is indicated by a 0.31

inch die hole at the top center of the

axle.

(5) Both spring seats (11) must be parallel.

(6) Place axle (9) in position under

s u s p e n s i o n . Be sure spring seats (11)

are equal distance from the axle beam

center hole. Spring seats (11) should

a l s o be the same distance from the brake

spiders.

(7) Spring seats (11) must fit tight to the

WELD POINTS

axle beam.

WARNING

W e a r welding mask, gloves, and apron when welding or

using cutting torch. Failure to wear adequate protective

clothing may result in serious injury.

CAUTION

Do not attach welding ground clamps to U-bolts, springs,

o r axles except at designated weld points. These parts

should be protected from weld spatter.

( 8 ) T a c k w e l d s p r i n g s e a t s ( 1 1 ) i n p l a c e . T h e n recheck to be certain that the

spring sea ts ( 11 ) are still

level, parallel,

properly located and alined.

L o w e r axle (9) .

(9) Weld spring seats (11) to axle (9) using 3/8 inch fillet welds. Welds

s h a l l be per Class 2, MIL-STD-1 261.

d. Axle

Installation

(1) If necessary, install brake camshafts (para. 4-35).

5-4