TM 9-2330-388-14

f.

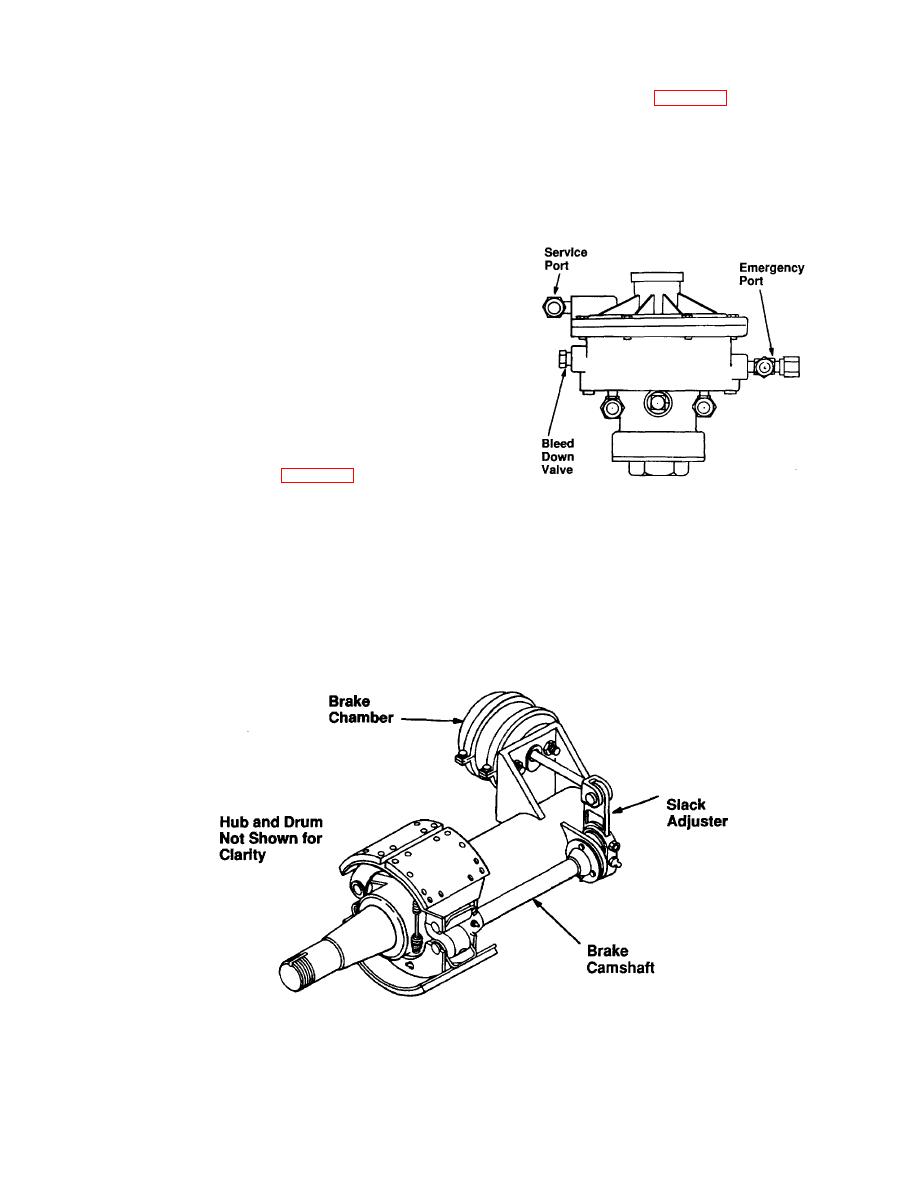

Fail-Safe Units, Fig. 4-43. The fail-safe units

(2) When there is enough reserve air in front

reservoir, the spring brakes can be released opening a

are spring chambers which are assembled piggyback on

valve on the roadside of the semitrailer.

the brake air chambers. One is installed on the air

chambers at each of the four corners of the tandem axle

d.

Service Brake. When the towing vehicle is

assembly. The fail-safe unit provides parking and

attached, the foot brake operates the brakes on both the

emergency braking.

semitrailer and the towing vehicle.

(1) Air pressure of approximately 65 psi is

(1) Applying the brake pedal delivers through

the service line to the emergency relay valve.

(2) In response to the service signal, the

emergency relay valve releases air form the rear

reservoir to the brake chambers. Air pressure causes

the camshaft in each brake assembly to rotate and force

the brake shoes against the brake drum.

(3) Releasing the brake pedal stops the service

signal to the emergency relay valve. the emergency

relay valve closes the supply from the reservoir and

releases air from the brake chambers.

e.

Emergency Relay Valve, Fig. 4-42. This valve

increases the speed at which brakes apply and release.

Figure 4-42. Emergency Relay Valve

The relay valve is attached to the rear reservoir above

the forward axle.

needed to release the fail-safe units.

(1) The emergency relay valve releases air

(2) Loss of air pressure will release the heavy

from the rear (primary) reservoir to all brake chambers in

spring and push the piston against the diaphragm plate

response to the service signal from the towing vehicle.

of the air chamber. This force is applied through the

camshaft to the brake shoes.

(2) The emergency relay valve will also cause

the fail-safe brakes to apply automatically if the semi-

g.

Slack Adjusters. These convert linear motion of

trailer breaks away from the towing vehicle.

the brake chamber to rotating motion of the camshaft.

Figure 4-43. Brake Actuator Assembly (M1098)

4-107