C9, TM 9-2350-230-12

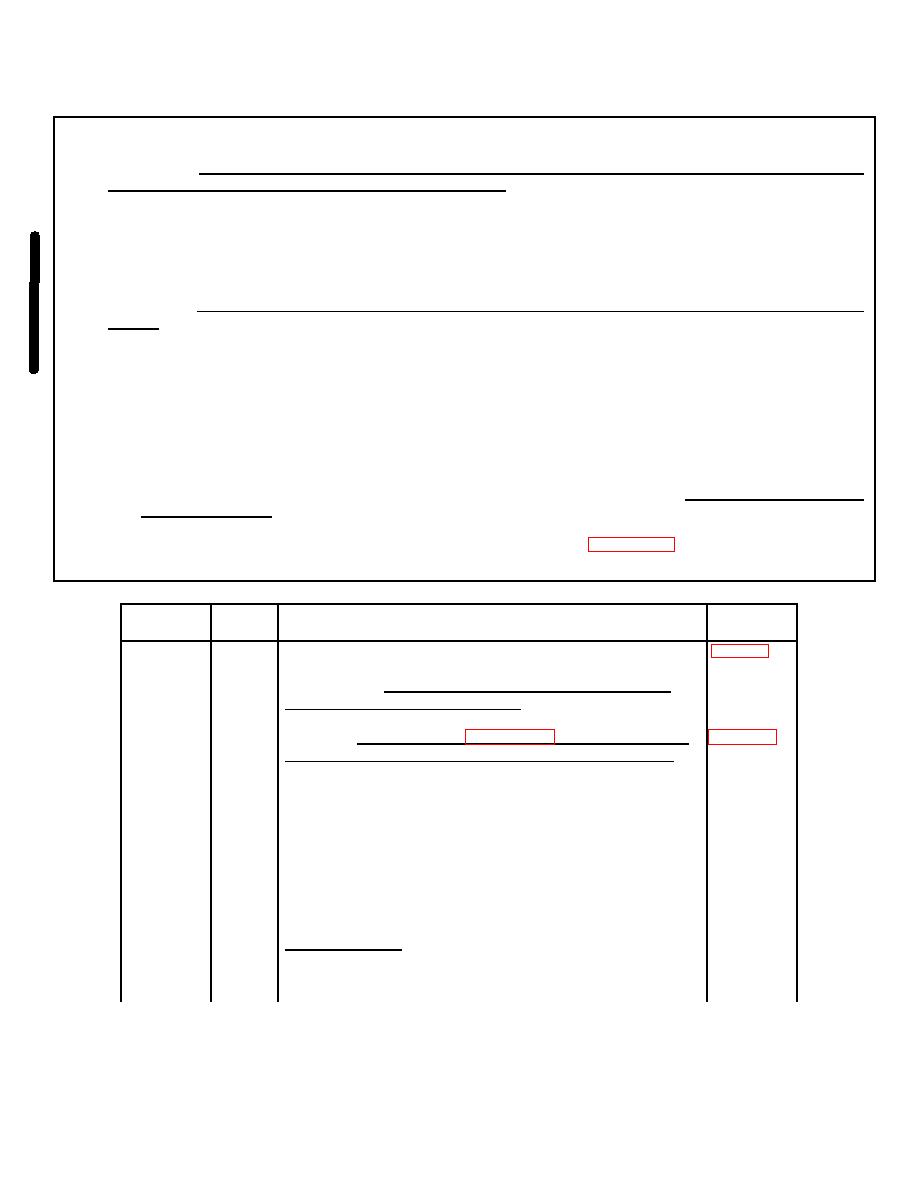

TABLE 5-8.1. CLEANING AND LUBRICATION OF GUN LAUNCHER - CONT'D.

3. Wipe dry with clean, lint-free cloth and blow out detent cavity with dry compressed air.

NOTE. On vehicles equipped with closed breech scavenger system, close breech and activate scavenge

system manually to clear check valve discharge port in tube.

4. Visually inspect for complete removal of residue, rust, and foreign matter.

5. Coat all cleaned surfaces with lubricating oil PL-S. Spread oil with a clean saturated cloth or brush. Leave breech

backed out but not rolled over to permit air circulation and reduce condensation.

NOTE. If cannon will not be fired for one month or longer, use grease, aircraft and instrument GIA (MIL-G-

23827).

6. Monthly thereafter, when cannon is not being fired, clean with RBC, wipe dry and relubricate as indicated in

Step 5.

6A. In geographical areas where temperature variations create excessive moisture by condensation, crew

maintenance should include WEEKLY removal of gun launcher dust shield, drying of all affected components

and assuring that exposed portion of recoil mechanism sleeve is free of corrosion or rust. External surface of

exposed sleeve may be thinly coated with Silicone Compound MIL-S-8660.

7. Wipe dry before firing all areas except breech chamber and coupling buttress threads. Maintain lubricant on these

threads at all times.

8. Notify organizational maintenance to service check valve and/or detent (table 8-17. 1).

TABLE 5-9. DISASSEMBLY/ASSEMBLY - 7.62MM MACHINE GUN

DISASSY

ASSY

PROCEDURE

FIG/ITEM

STEP

STEP

Removal/installation of machine gun from vehicle.

machine gun and chamber cleared.

disassembly sequence, black arrows, assembly sequence.

1

13

Barrel extension assembly is in rear position (charged),

place trigger safety in the fire "F" position. Pull charger

handle rearward and, while keeping tension on handle,

depress manual firing trigger, allowing barrel extension

to go forward slowly. Charge the machine gun, then

place safety in safe "S" position. Depress the manual

firing trigger. If the barrel extension assembly is

released, notify organizational maintenance personnel.

Functional Check - Check the functioning several times by

pulling charger to rear, and while maintaining tension

on handle, depress the manual firing trigger. Barrel

extension must release with safety in fire "F" position.

5-24.2