C4, TM 9-2350-230-12

9-9. Engine Fuel System (Fig. 9-17)

a. Checking Fuel Flow.

(1) Insert end of a wire through one of the pump

body drain holes, then crank engine momentarily

(1) Open exhaust grille doors, disconnect fuel return

and see if wire vibrates. Vibration will be felt if

hose at quick disconnect (Fig. 9-4), remove

pump shaft rotates.

disconnect from hose and place end of hose in a

(2) Without removing pump from engine, unscrew

one gallon container.

valve plug; and remove gasket, spring, pin, and

(2) Start and run engine at 1200 rpm and measure

valve. Wash parts with solvent and blow out

the fuel flow return for a period of one minute.

valve cavity with compressed air. Install valve

Approximately one-half gallon of fuel should flow

parts and check flow.

from the return hose per minute.

9-10. Engine Coolant System (Fig. 9-28)

(3) Immerse end of fuel hose into fuel container. Air

bubbles rising to the surface of the liquid will

a. When coolant system has been drained to service

indicate a leak on the suction side of the pump.

coolant components, the system should be flushed to

Check all hose connections and gaskets on

remove scale deposited by hard, mineral-laden water.

strainer and filter elements.

(1)

Drain system (table 5-4).

(4) If the fuel flow is insufficient for satisfactory

engine performance, then check the strainer

(2) Refill system with clean soft water. If engine is

element and filter element and replace either or

hot, fill slowly to prevent distortion of engine

both if clogged. Start engine and run it at 1200

castings.

rpm to check fuel flow. If fuel flow is still

unsatisfactory, replace fuel pump (fig. 9-19) and

(3) Start engine and operate for 15 minutes.

again check flow. When changing a fuel pump,

clean pump lines with compressed air and be

(4) Drain coolant system completely (table 5-4).

sure all fuel line connections are tight.

(5)

Refill cooling system according to Table 9-2.1.

(5) Connect fuel return hose to quick disconnect.

b. Whenever hose connections have been disturbed or

b. Checking Fuel Pump. If the fuel pump fails to

when coolant system has been drained, retorque clamps

function properly, check for broken pump shaft or dirt in

to 40-60 pounds-inches after engine has been operated

relief valve before removing the pump from the engine:

to normal operating temperature.

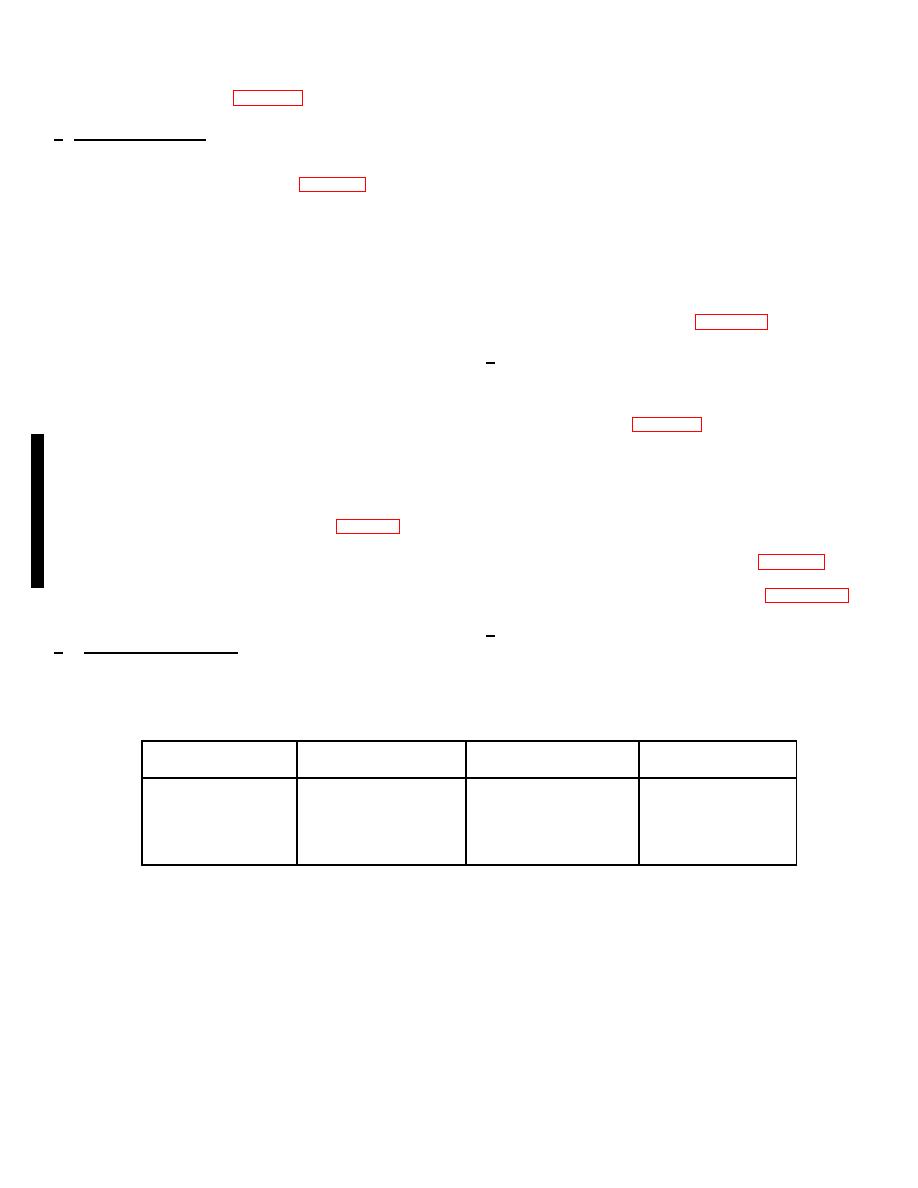

TABLE 9-2.1. COOLANT MIXTURE

AMBIENT

TEMPERATURE

ANTIFREEZE

INHIBITOR

-65F to -40F

6850-174-1806

--------

Full strength

6850-243-1992

--------

-40F to+80F

or

--------

50-50

6850-224-8730

--------

Above 80F

--------

6850-753-4967

22-1/2 oz.

9-14