TM 9-2590-209-14&P

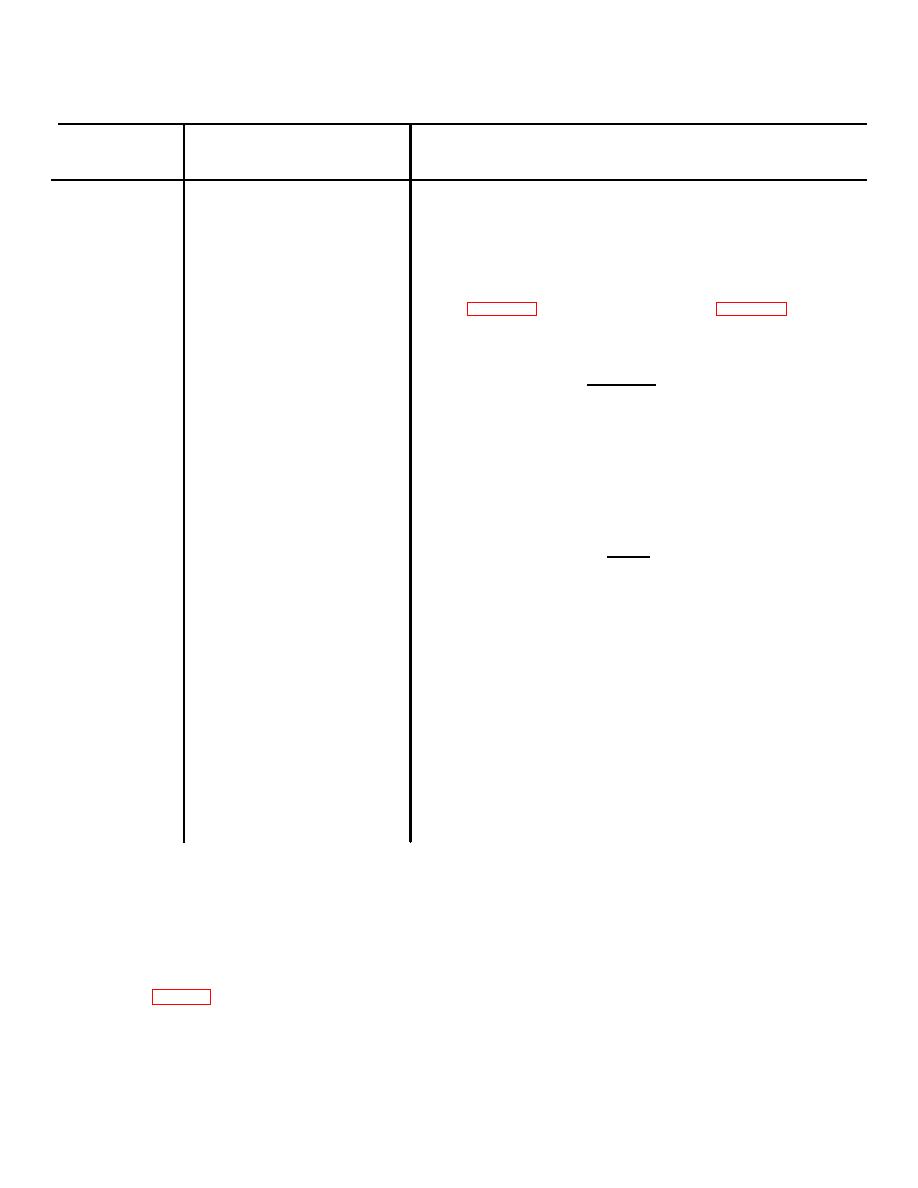

Table 4-1. Organizational Preventive Maintenance Checks and Services Quarterly Schedule

Item

Item

To Be

No

Inspected

Procedures

7

Tubing,

Inspect all tubing and hoses for cracks, dry brittle conditions,

Hoses, and

missing or damaged parts

Inspect all fittings for leaks.

Fittings

8

Reservoir

Check oil level. Check lines and fittings for leaks. At oil

change, inspect filters for evidence of restriction. Refer

filter removal. Clean filters as necessary with dry-cleaning

solvent (PD-680).

CAUTION

Oil in reservoir must be maintained at proper level for satis-

factory performance of the pump.

9

Right-Angle

Operate blade assembly to determine that magnetic clutch

Drive Power

is operating.

Takeoff

Assembly

NOTE

If operation of blade assembly is slow or jerky, check oil

level in reservoir and refill if necessary.

10

Pump

Inspect pump for leaks, loose mounting, loose connections

and signs of physical damage. Check for signs of overheating

(cracked, blistered, or discolored paint).

11

Magnetic

Inspect for loose electrical connector Check oil level

Clutch

in magnetic clutch.

12

Blade

Check blade assembly control lever for free operation.

Assembly

Check that blade assembly raises, lowers, and holds in re-

Manual

sponse to position of control lever.

Control

Lever

Section III. MAINTNANCE OF HEADLAMP ADAPTER

4-7. Description. Headlamp adapters are mounted to

NOTE

vehicle headlamp receptacles to raise the headlamps,

permitting illumination when the M9 bulldozer blade is in

the raised position. Two guards protect the headlamps

Procedures for left side and right side are the same.

from brush or debris damage.

4-8. Removal (Fig 4-2).

4-5