TM 9-3405-206-14 & P

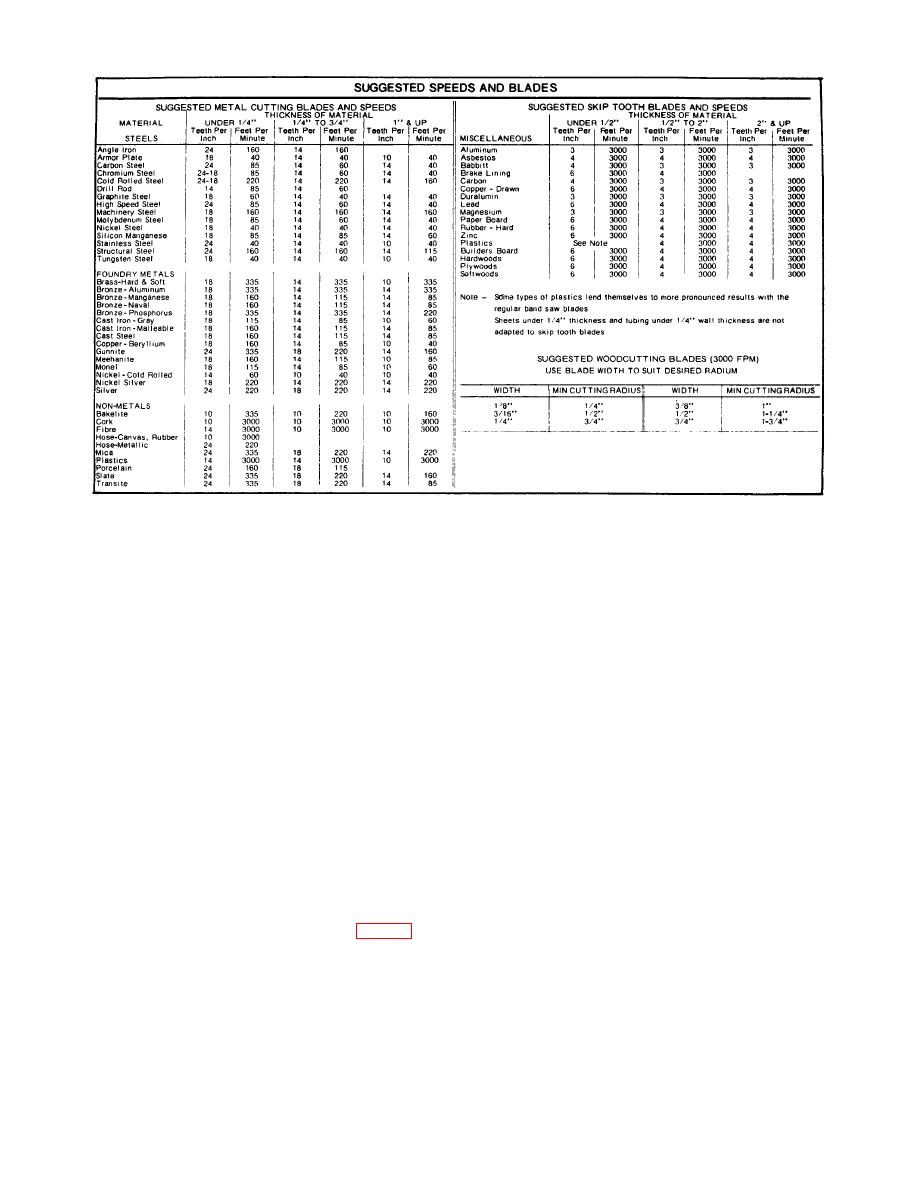

Fig. 23

BAND SAW BLADE

no equipment for filing, set and braze or weld blades

A band saw blade is a delicate piece of steel that is

take them to a saw filer for reconditioning.

subjected to tremendous strain.

It is not practical to re-sharpen either the skip tooth

Be sure to use blades of the proper thickness, width, and

blades or the regular hard-edge flexible-back metal

temper for the various types of material to be cut.

cutting saw blades.

Always use the widest blade possible. Use the narrow

Any One of a number of conditions may cause a band

blades only for sawing small, abrupt curves and for fine

saw blade to break. Blade breakage is, in some cases,

delicate work. This will save blades and will produce

unavoidable, being the natural result of the peculiar

better work. Band saw blades may be purchased,

stresses to which such blades are subjected. It is,

welded, set and sharpened ready for use. For cutting

however, often due to avoidable causes, most often to

wood and similar materials they are available in widths of

lack of care or judgment on the part of the operator in

1/8, 3/16, 1/4, 3/8, 1/2 and 3/4 inches.

mounting or adjusting the blade or guides. The most

common causes of blade breakage are: (1) faulty

Blades for metal cutting should be selected for the

alignments and adjustments of the guides, (2) forcing or

particular job they are to do. Blades for cutting thin

twisting a wide blade around a curve of short radius, (3)

metal, for example, should be selected so that there will

feeding too fast, (4) dullness of the teeth or absence of

always be at least two teeth in contact with the edge of

sufficient set, (5) excessive tightening of the blade, (6)

the work. If the teeth are allowed to straddle the work

top guide set too high above the work being cut, (7)

they will be torn off and the blade ruined.

using a blade with a lumpy or improperly finished braze

Generally speaking, thick stock requires larger teeth and

or weld and, (8) continuous running of the saw blade

a slower cutting speed than thin stock. See Fig. 23 for

when not in use for cutting.

recommendations of blades and cutting speeds for

New blades for the standard 14 inch band saw are 931/2

different materials and thickness.

inches long. The adjustment will accommodate blades

File and set the wood cutting blades whenever it requires

up to a maximum length of 94 inches and to a minimum

pressure to make them cut. If a blade is broken it can be

length of 911/2 inches. When equipped with the No. 28-

brazed or welded; however, if it has become badly work-

984 Height Attachment, new blades should be 105

hardened it will soon break in another place. If there is

inches long; maximum and minimum lengths are 106

and 1031/2 inches.

16