TM 9-3405-206-14 & P

OPERATING THE BAND SAW

CUTTING CURVES

Before starting the machine, see that all adjustments are

When cutting curves, turn the stock carefully so that the

properly made and the guards are in place. Turn the

blade may follow without being twisted. If a curve is so

pulley by hand to make sure that everything is correct

abrupt that it is necessary to repeatedly back up and cut

BEFORE turning on the power.

a new kerf, either a narrow blade is needed or a blade

with more set is required. The more set a blade has, the

Keep the top guide down close to the work at all times.

easier it will allow the stock to be turned, but the cut is

Do not force the material against the blade too hard.

usually rougher than where a medium amount of set is

Light contact with the blade will permit easier following of

used.

hardening of the blade at its back edge.

In withdrawing the piece being cu!, in order to change the

cut, or for any other reason, the operator must be careful

KEEP THE SAW BLADE SHARP and there will very little

that he does not accidentally draw the blade off the

forward pressure required for average cutting. Move the

wheels. In most cases it is easier and safer to turn the

stock against the blade steadily and no faster than will

stock and saw out through the waste material, rather

give an easy cutting movement.

than try to withdraw the stock from the blade.

Avoid twisting the blade by trying to turn sharp corners.

Fig. 24

LUBRICATION

The gear case is filled at the factory with 11: quarts of

oil. It should be drained after 1500 to 2000 hours of

operation and refilled with a good grade of heavy

adhesive gear oil. A pipe plug is provided underneath

the band saw and is removed when draining the oil.

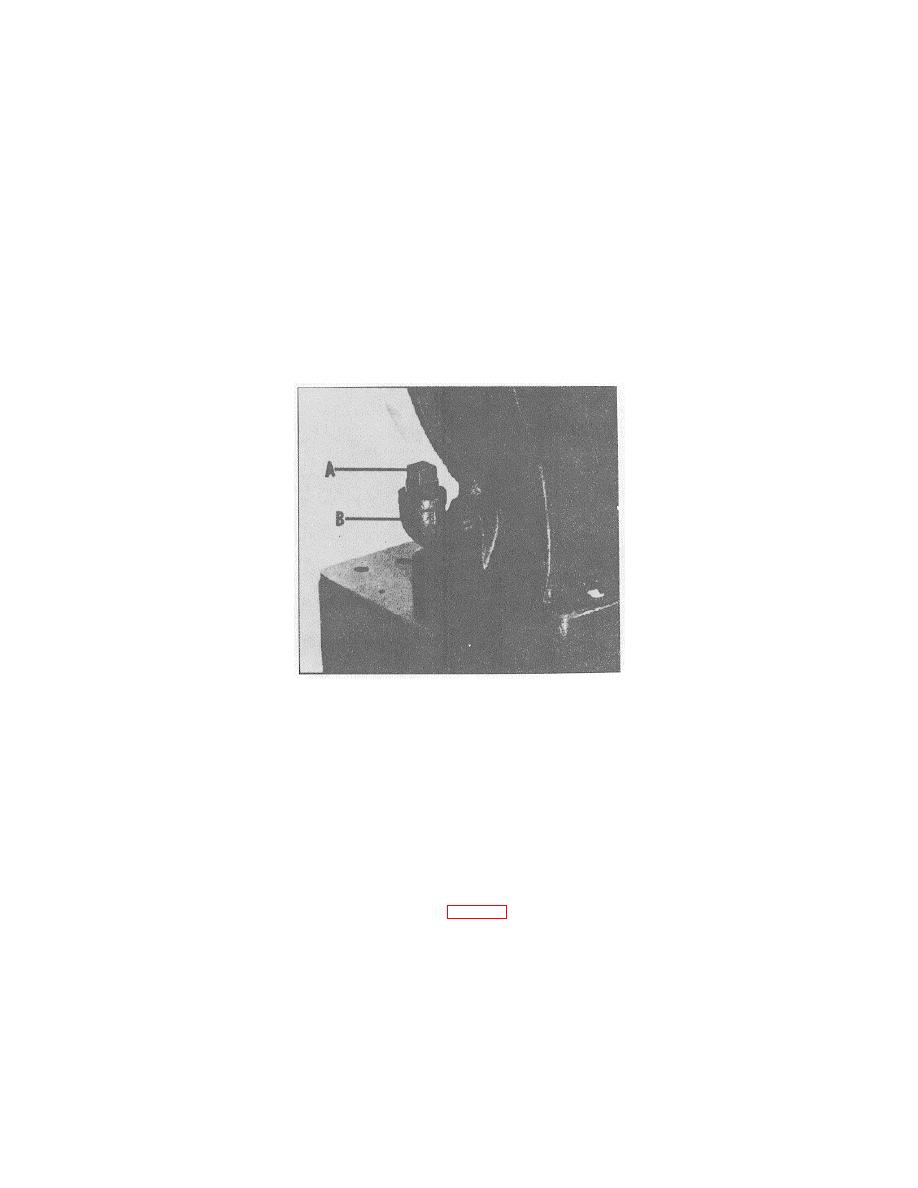

All models are equipped with a ,2-inch street elbow (A)

Fig. 24, and a pipe plug (B).

Remove the pipe plug (B) Fig. 24, to check the level of

oil in the gear case from time to time and keep it filled to

insure proper gear lubrication.

The wheels of the band saw are turned on permanently

sealed ball bearings, which require no lubrication. Ball

bearing blade supports are of the same type. Oil of

every kind should be kept away from the blade

supports.

17