(3)

Remove table center plate and post saw guard.

Install a 1-inch wide saw band and apply cor-

rect band tension.

(4)

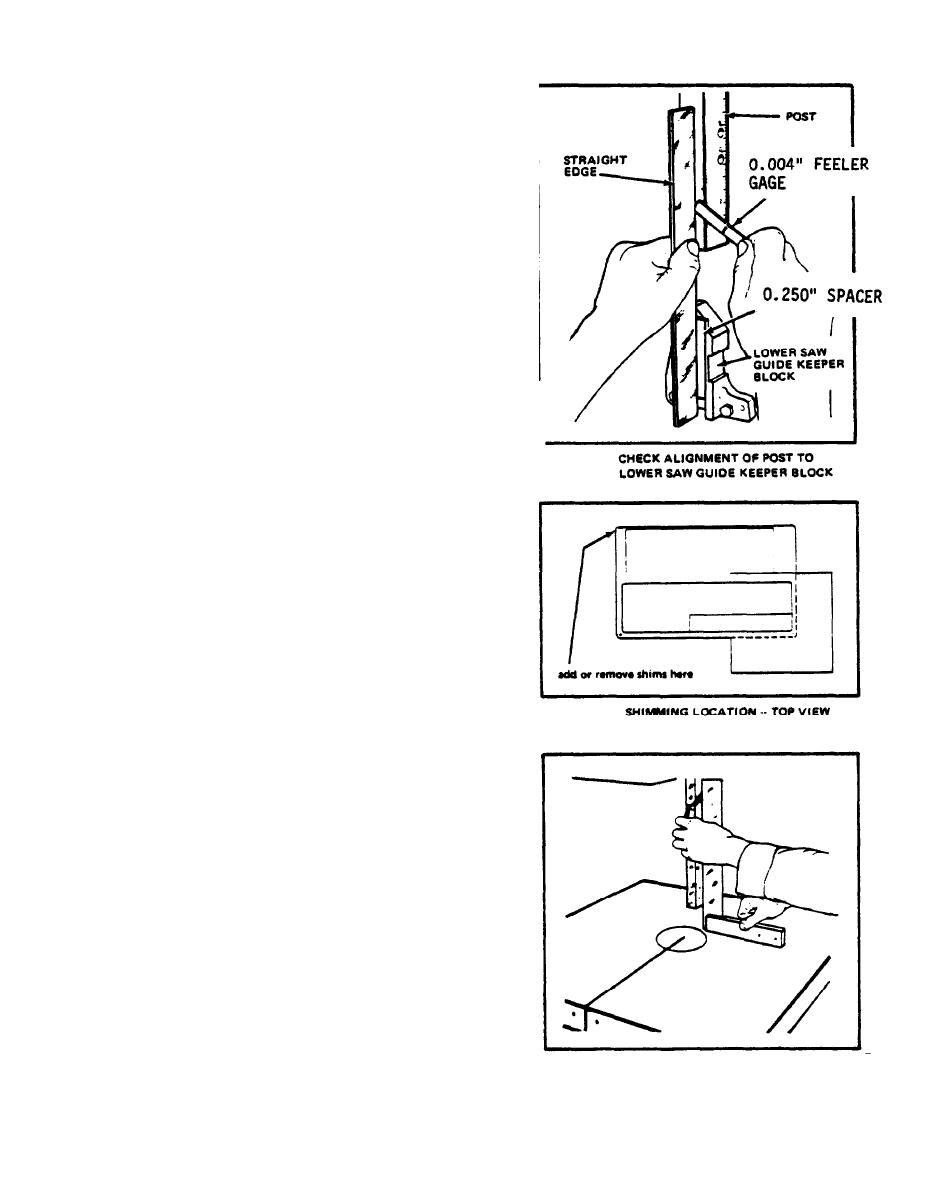

Clamp or hold a straight edge to the front face

of the post and the face of the lower saw guide

keeper block.

(5)

The post should be parallel with the machined

saw guide mounting recess in the lower keeper

block. As shown in the sketch, this parallel-

ism is checked by placing a spacer block

(ground to exactly 0.250" thickness) in the

keeper block. T h e n p l a c e a n a c c u r a t e s t r a i g h t

edge against this spacer block and the post.

Using a feeler gage, check the clearance and

parallelism of the post to the straight edge.

A clearance of 0.004" or less is required.

(6) Adjust the gap by adding shims (to increase

gap) or removing shims (to decrease gap) under

only the mounting bolt location shown in draw-

ing.

(7)

Replace table center plate and post saw guard.

(8)

Loosen table tilt trunnion lock nut with the

wrench furnished with the machine. Square the

table to the post and check as shown above.

Tighten the trunnion lock.

(9)

If necessary, adjust the tilt angle pointer to zero.

(10) The back of the band should be just touching

the saw guide back-up insert. Adjust upper

wheel tilt, if necessary, so that band is posit-

ioned and will track properly. (See Track-

ing the Band in Operation Chapter).

SQUARE TABLE TO POST AND

TIGHTEN TABLE TILT LOCK

3