9. BLADE SPEED

9.4 See recommended blade speeds later in this

booklet (Section 13, table of blade speeds and

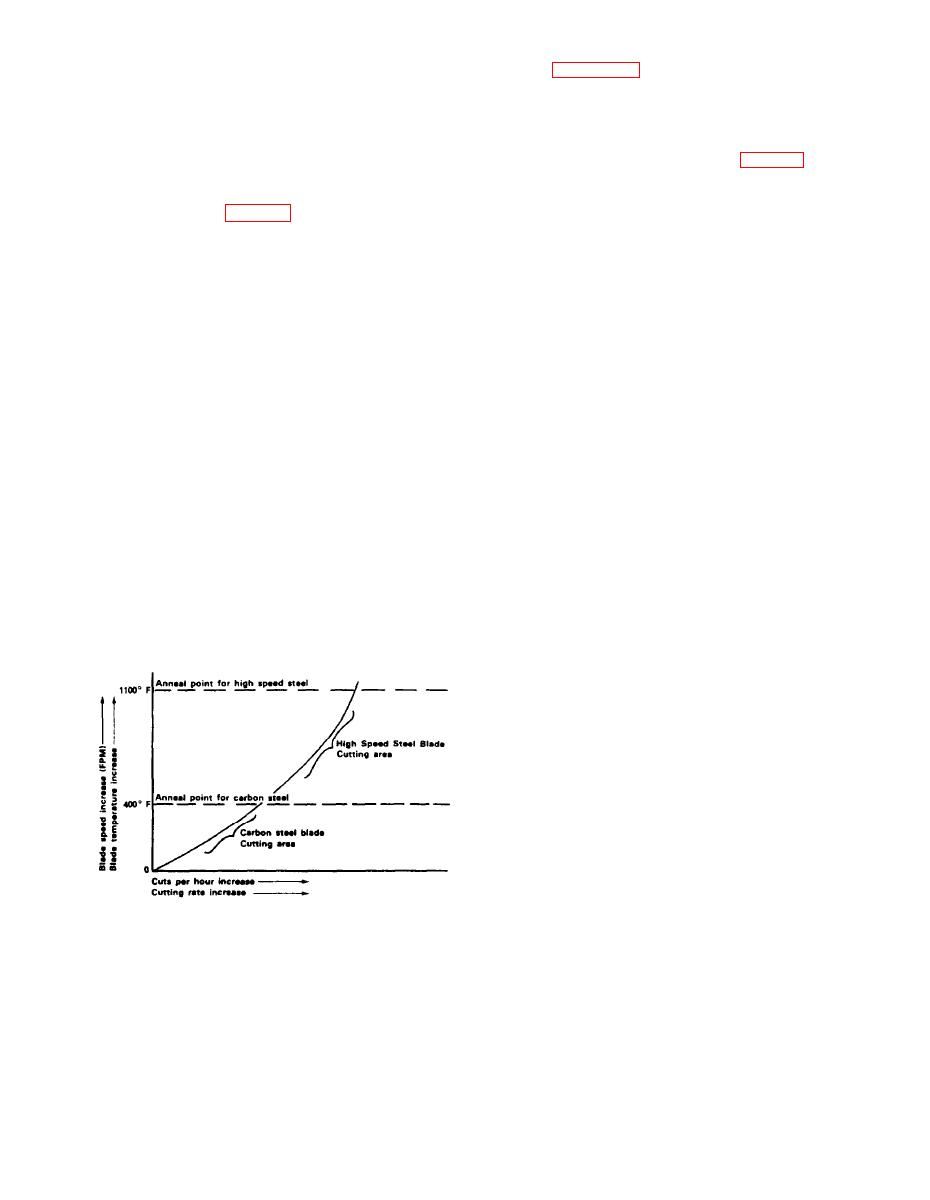

9.1 Blade speed is measured in feet per minute of

cutting rates).

blade travel. Slower than normal speeds will not

harm the blade. Faster than normal speeds will

10. ACCURACY OF CUT

generate excess heat and will quickly destroy the

cutting edge of the blade. Blade speed selection is

10.1 Accuracy of cut is shown in Fig. 8-1. The

a compromise between good blade life, number of

blade should be run on the conservative side in

cuts per hour, and keeping the heat generated to an

order to keep maximum tooth sharpness. Proceed

acceptable level. Fig. 9-1 shows this graphically.

as follows for maximum cutting accuracy:

A. Use less cutting force

9.2 Small work can be cut at higher speeds due to

B. Use less blade speed

the short time during which the cutting edge is in

C. Use maximum blade tension for highest

contact with the work. As the work size becomes

beam strength

larger, the blade speed becomes slower to compen-

sate for the longer contact time and more heat gen-

This technique is suggested for tool room cutting

erated per tooth contact. When cutting large solid

where time is not important, but where the highest

blocks 20 inches and over, the cutting speed should

percentage of straight cuts is necessary. However,

be reduced 15% to 30% from the average speeds

straight cuts can also be made in production

shown on the cutting charts. This will compensate

cutting. The possibility of slight run-off is higher,

for the extra long blade contact.

and the chance of a blade breakdown during a

critical job is much more likely.

9.3 If a good blade life is obtained at the given

speeds, it may be possible to increase the cutting

speed for better production. On production cutting,

increase the blade speed 5% to 10% each time a new

11. PRODUCTION CUTTING

blade is installed. When the new blade fails to equal

Maximum production speed should be based on al-

the number of cuts made by the last blade, reduce

lowable blade life.

the speed to that of the last blade. This can soon

reveal the best speed for your particular job.

11.1 If more production per hour is necessary, use

the highest reasonable speeds and feeds. This will

FIG. 9-1

result in less blade life but more production. Total

cost per cut with all overhead expenses included

TEMPERATURE DUE TO BLADE SPEED

may be the least overall cost.

This is a figure each must compute for himself

as much depends upon work load. Many shops

want minimum blade cost per cut and use carbon

steel blades with slower production rates. Others

use automatic equipment with high speed steel

blades with maximum cutting conditions. This will

often give the lowest cost per cut when total over-

head is used to compute cost.

11