4. Special instructions for truing other honing. units see literature supplied with the unit.

REDUCE RUN-OUT OF HONING UNIT

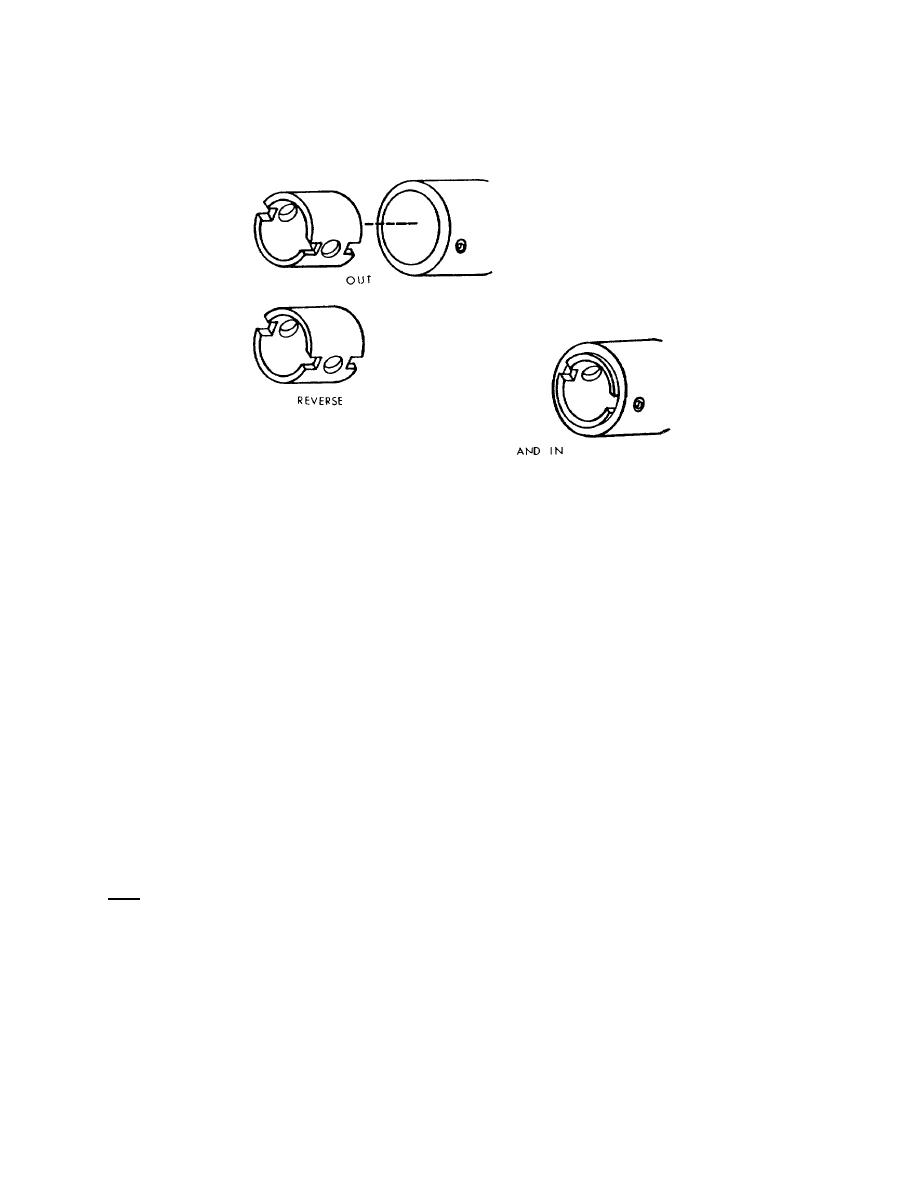

To reduce run-out simply reverse the position in the spindle chuck, screwing chuck screw into opposite

side of compensator thus: ,

ADJUST THE STROKING STOP (Optional extra equipment

Part No. AC 42., if used)

The stroking stop is adjustable and can be set to limit the depth of the honing stroke, as is necessary when honing

blind holes. With motor turned OFF, place work piece on honing unit and adjust stroking stop to allow desired stroke.

Tighten thumb screw.

ADJUST THE WORK SUPPORT (if used)

With the work support mounted on honing machines one is assured of more accurate results when honing long

unbalanced parts such as rotor housings, connecting rods, links, etc. It absorbs torque surges caused by out-of-round

holes, reduces operator fatigue, and speeds the honing procedure. It is a must for external honing, except honed parts of

less than 1 inch with tolerances of 10 - 50 millionths, etc. Three separate adjustments provide quick setting of the bar to

handle work of different lengths. The bar should be placed approximately under center of gravity of work if hole is

considerably off center.

HONE THE PARTS

1. Being sure the motor switch is OFF, back off feed knob dial all the way (counterclockwise). (Do not force it,

however, as it has been precision calibrated.) Place the work piece on honing unit so that it is centered on stone. Depress

foot pedal and adjust feed knob dial to bare contact. Seat part on stone by turning it slightly clockwise. Adjust feed knob

dial again until slight contact is made, but not more than amount of stock to be removed. Release foot pedal.

Note: Many operators prefer a square contact when honing in a new part to provide a y stone effect. Stone may

be squared on a stone dresser, Part No. TS 2750-3. The leading edge should be slightly broken to prevent slide galling.

Stones may be ordered square cut and broken.

7