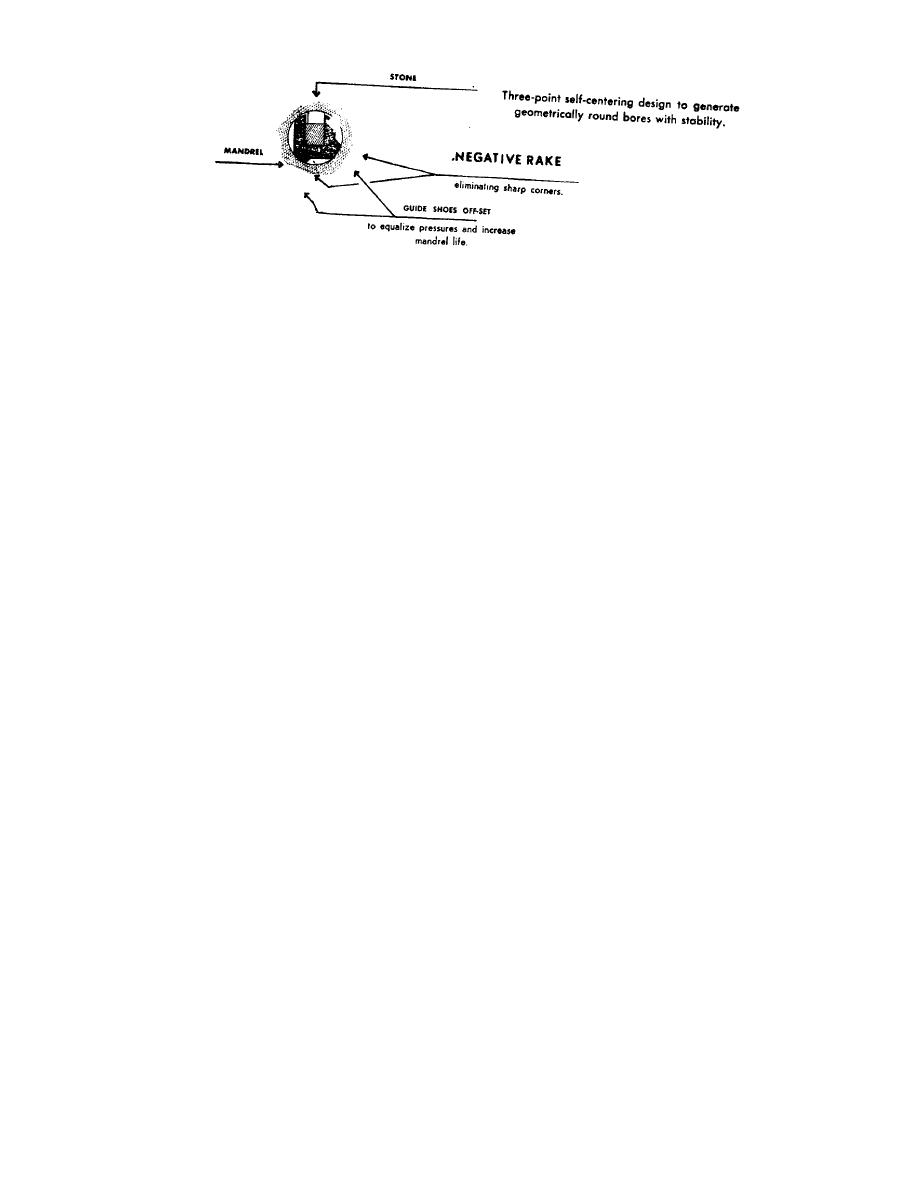

MANDRELS

1. The proper off-set position of the shoe guides assure equalized pressures for balanced wear and smooth

precision honing throughout the life of the mandrel.

2. The negative rake on the leading edges of the shoe guides eliminate any tendency to chatter, grab, or ream

the work.

3. Extended mandrel life by greater stability and uniform coolant distribution.

ALTERING STONES AND SHOES

The mandrels, stones, and parts can do most jobs without any alteration. Occasionally as the tolerances on the

straightness of the hole decrease to .0001" or less, for example, the length of the stone in relation to the hole becomes

more important. In order to hold such close tolerances on straightness, it may be necessary to shorten both stone and/or

shoes. Maximum straightness is produced when stone and shoes are about 2/3 the length of the hole; however, for

stability in very short holes, it may be necessary to use a stone that is 3/4 the length of the hole, or even full length. When

honing to closer tolerances (e.g. 20-50 millionths range), the skilled operator can easily develop fit by deducting or

removing slight amounts of shoe metal from the shoe contact area (e.g. total in square inches) and thus provide for even

contact.

10