TM 9-3431-254-14&P

GROUNDING

10 feet (3048 mm) from the unit. The ground wire must

The frame of this unit should be grounded for personnel

be No. 8 size or heavier.

safety. Where grounding is mandatory under state or lo-

cal codes, it is the responsibility of the user to comply

NOTE: The ground wire must be as

with all applicable rules and regulations. Where no state

short as possible in order to produce

or local codes exist it is recommended that the National

the most efficient installation.

Electrical Code be followed.

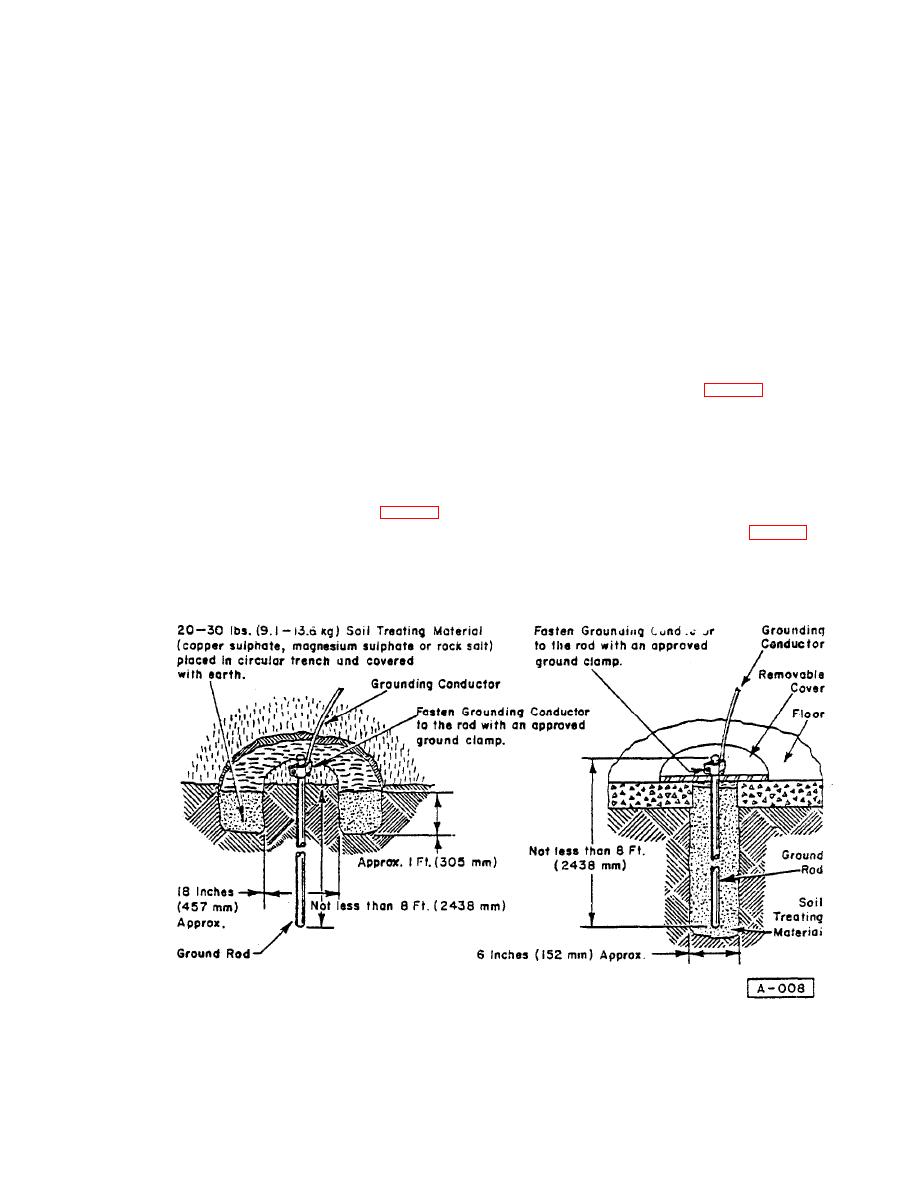

TREATING AN OUTSIDE GROUND - The soil

These requirements and recommendations apply to rub-

treating materials are placed in a circular trench around

ber-tire mounted equipment as well as other equipment.

the rod, but not in direct contact. The crystals are

In addition to the usual function of protecting per-

gradually dissolved by surface waters and the solution is

carried into the most useful area of earth surrounding

sonnel against the hazard of electrical shock due to fault

in the equipment grounding serves to discharge the

the electrode (rod). Flood the trench several times when

static electrical charges which tend to build up on the

making original installation. See Figure 4.

surface of rubber-tire mounted equipment.

WARNING

These static charges can cause painful shock to personnel,

TREATING AN INSIDE GROUND - Reduce the

and can lead to the erroneous conclusion that an electrical

diameter of the hole to 6 inches (152 mm), pour soil

fault exists in the equipment.

treating material in around the rod. Add enough water

If a system ground is not available, the unit's frame must

to dissolve 8 pounds (3.62 kg) of soil treating material.

be connected to a driven ground rod (see Figures 4 and 5)

Flood the hole every 6 months and replace the soil treat-

or to a water pipe that enters the ground not more than

ing material when it is all dissolved. See Figure 5.

Inside Ground

Outside Ground