FEATURES

The Series 0800 Sheer is equipped with

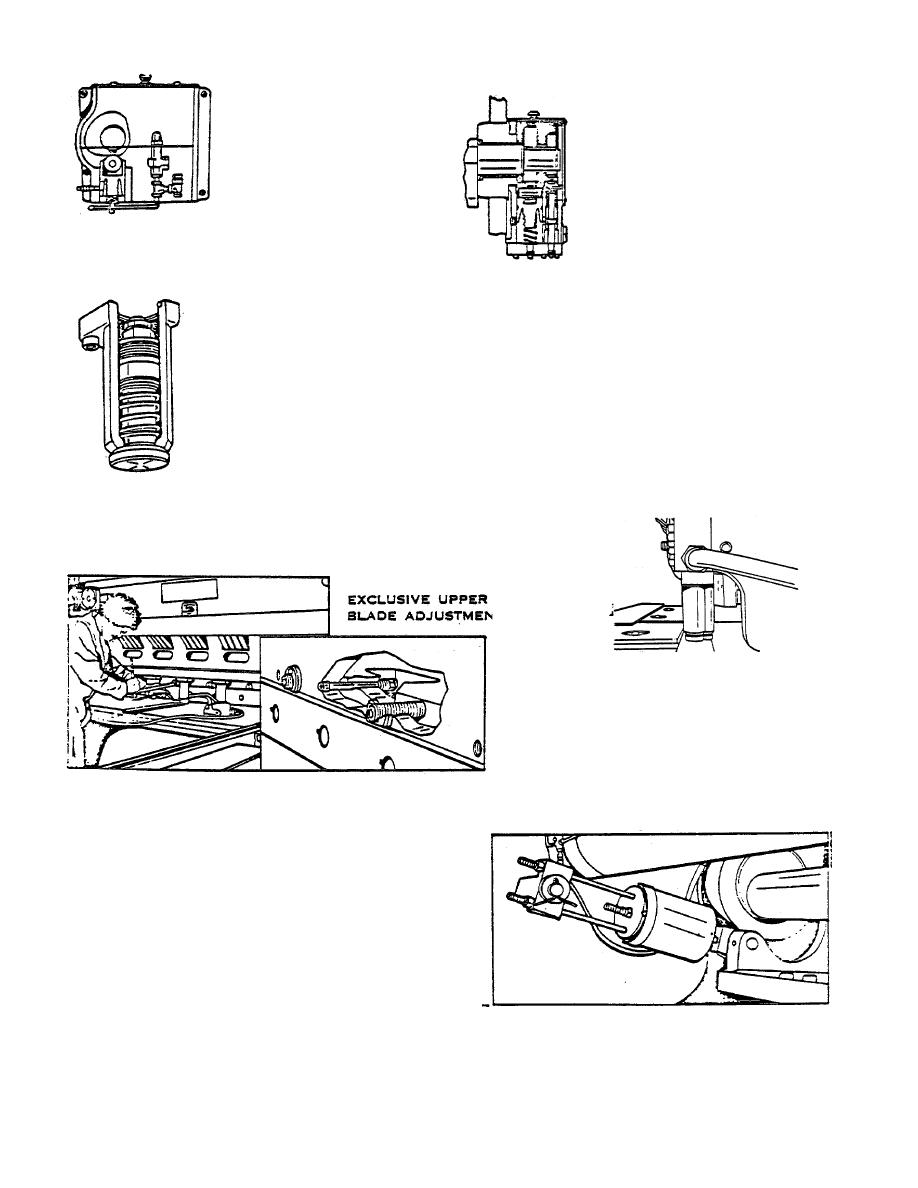

HYDRO-HOLD

a specially designed hydraulic holddown

HOLDDOWN SYSTEM

system. The holddown pump case has

The entire system has been

two hardened cams attached to the end

designed to eliminate leakage

of the eccentric shaft.

and to minimize maintenance

time.

Pump cam and roller

One cam actuates a large piston to

have been designed to insure

furnish sufficient volume to bring all

long, trouble-free service.

All

holddown fingers to the shear table. The

drain plugs are magnetic to

second cam then actuates a small piston

guarantee clean hydraulic oil.

to build up the required pressure. This

two-pump arrangement is used to

eliminate

the

high

cam-load

concentration required of a one-pump

NEW HOLDDOWN FINGERS

system of sufficient size for the job.

Holddown fingers have been completely redesigned to

eliminate connector tubes, a constant source of high

pressure oil leaks. A new, chevron type of "Teflon" is

HOLDDOWNS

used for impact sealing.

Should the occasion arise,

INDIVIDUALLY ADJUSTABLE

individual fingers can be removed from the holddown bar

Adding further holddown versatility and

and replaced with a flat steel plate also offers its

convenience, holddown fingers have an

exclusive, silent, positive "Sof-Loc" holddown system as

eccentric design which allows a 180'

an optional extra for use on soft or highly polished

rotation and lets the finger be set as close

material or for extreme accuracy.

This system,

as %' or as far away as 2' from the cutting

precisely controlled by the operator, prevents even the

edge, depending on the machine size.

slightest impact mar.

Ram construction assures straight, clean cuts.

The

back brace is machined from solid steel plate.

Adjustment of the upper blade provides a simple method

of compensating normal deflection and errors in blade

grinding without the use of shims. Easily accessible

screws permit one man to make the adjustment in

minimum time.

SPRING COUNTERBALANCES

These support the weight of the ram, ram back brace and

back gauge assembly.

The counterbalances exert a

backward and upward force to maintain -maximum ram and

slide bearing contact, preventing improper blade clearance

or blade damage caused by "floating" of the ram. Spring

counterbalances are furnished on 0200, 0300 and 0400

series.

39