TM 9-4110-255-14

NOTE

Valve plate, suction valves, position springs, and dowel pins may come off when removing

cylinder head.

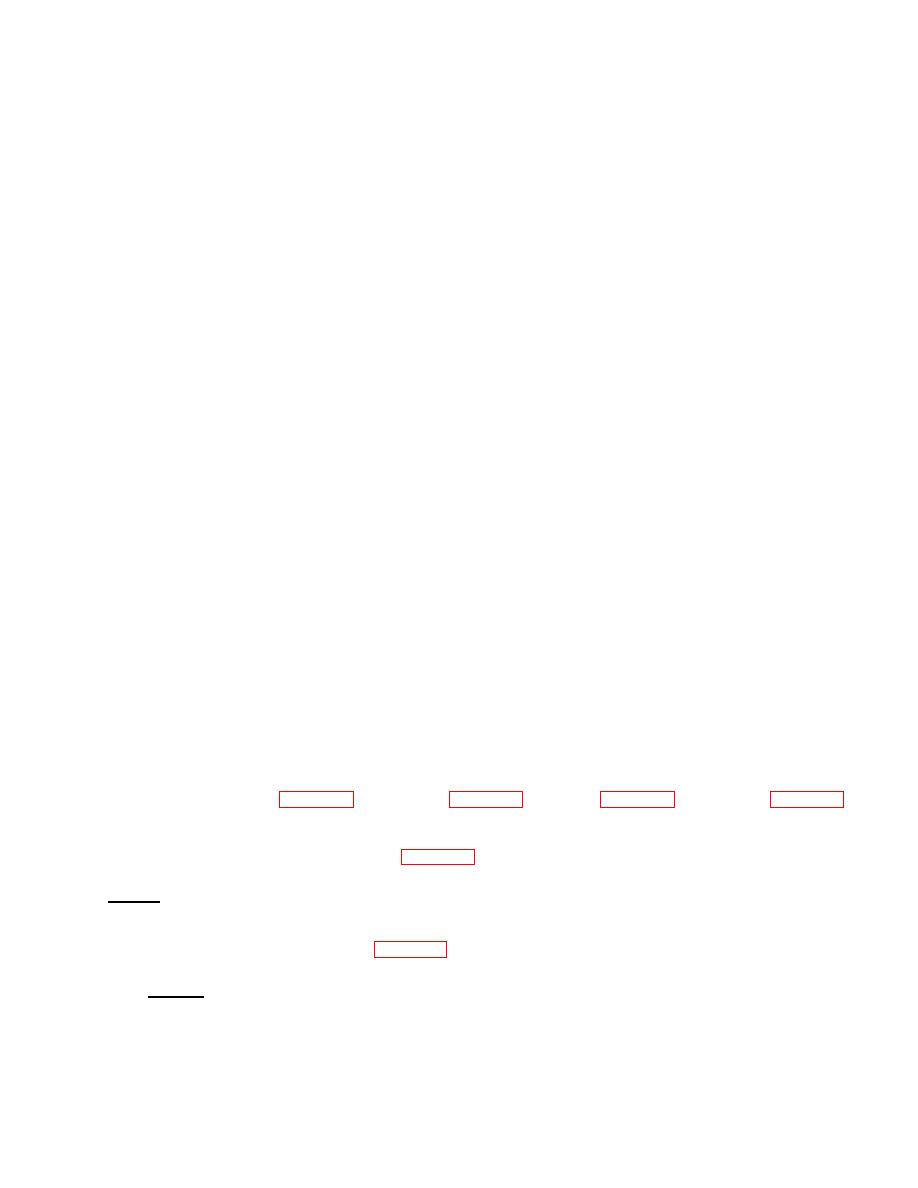

(4) Remove six screws (1), lifting lug (4), two studs (2), cylinder head (3), and cylinder head gasket (5).

Discard cylinder head gasket.

(5) Remove four screws (6), lock washers (7), two discharge valve stops (8), and discharge valves (9).

Discard lock washers and discharge valves.

(6) Install two screws (6), without lock washers (7), into the outermost discharge valves (9) mounting holes to

act as jackscrews to release valve plate (10).

(7) Remove valve plate (10), valve plate gasket (11), two suction valves (12), position springs (13), and four

dowel pins (14). Discard valve plate gasket and suction valves.

(8) Examine compressor (15) cylinder walls for any scoring or excessive wear indicated by a groove at top of

piston (16) travel. Replace compressor if scored or excessively worn.

(9) Press on top of highest piston (16). When pushed down, the piston should have some resistance and the

other piston should move. Repeat for other piston when at highest point. If either piston was loose or did

not cause the other one to move, replace compressor.

(10) If no failure was indicated, remove any gasket material from all machined gasket surfaces and install four

dowel pins (14), two position springs (13) contacting on the ends and bowed out in the middle, new suction

valves (12), new valve plate gasket (11), and valve plate (10).

(11) Check that suction valves (12) do not bind on valve plate gasket (11) by gently pushing on suction valve

through intake hole in valve plate (10). Adjust valve plate gasket as necessary to prevent suction valve

binding.

(12) Install two new discharge valves (9), discharge valve stops (8), four new lock washers (7), and screws (6).

(13) Install new cylinder head gasket (5), cylinder head (3), two studs (2), lifting lug (4), and six screws (1).

Torque screws and studs to between 40 and 55 ft-lb (54 and 75 Nm).

(14) Replace dehydrator (para 5-17). Leak check (para 5-13), evacuate (para 5-14), and charge (para 5-15) the

refrigeration system.

(15) Install and adjust compressor V-belts (para 4-38).

b. Service. Check compressor lubricating oil level at sight glass (17). Level should be between 1/8 and 1/2 way up

sight glass. Add or remove oil as necessary.

(1) Discharge the refrigerant system (para 5-10).

(2) Add Oil.

(a) Remove cap (18).

(b) Add oil as necessary through shrader valve (19).

(c) Install cap (18).

5-73