TM9-4120-370-14

TO35E9-229-1

Section Ill. TECHNICAL PRINCIPLES OF OPERATION

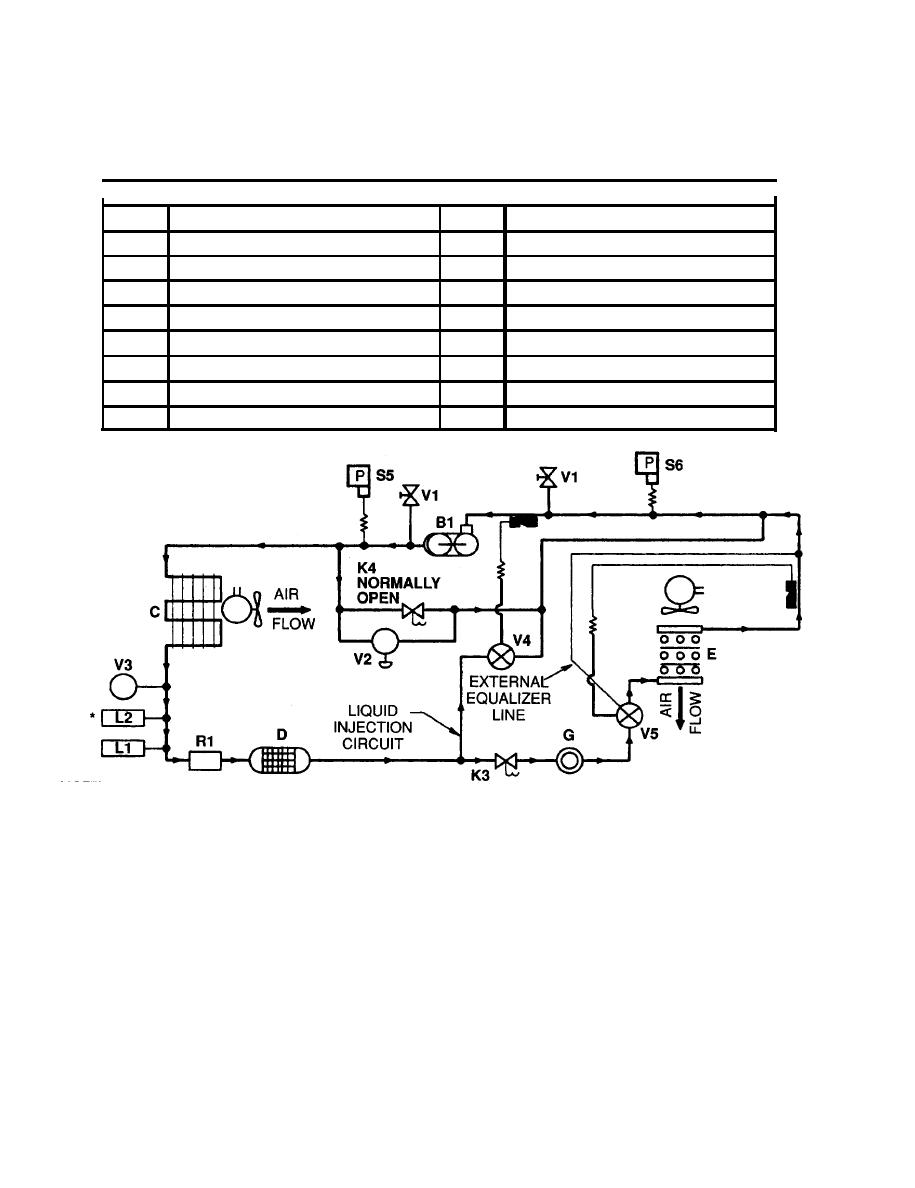

1-11. REFRIGERATION CYCLE

LEGEND

SYM

DESCRIPTION

SYM

DESCRIPTION

B1

COMPRESSOR, RECIP PDVN

R1

TANK, RECEIVER

c

COIL, CONDENSER

S5

SWITCH, HIGH PRESSURE CUTOUT

D

DEHYDRATOR, DESICCANT

S6

SWITCH, LOW PRESSURE CUTOUT

E

COIL, EVAPORATOR

v1

VALVE, ANGLE

G

INDICATOR, SIGHT, LIQUID

V2

VALVE, PRESSURE REGULATING

LI

LINEAR ACTUATING CYLINDER

V3

VALVE, PRESSURE RELIEF

L2*

V4

LINEAR ACTUATING CYLINDER

VALVE, EXPANSION

K3, K4

VALVE, SOLENOID

V5

VALVE, EXPANSION

* NOTE

NORMALLY

THE L2 LINEAR ACTUATING CYLINDER IS USED ONLY OPEN

ON MODELS F36T-2S, F36T4-2S, AND F36T4-2SA

a.

Cooling cycle - Unit operation with mode selector switch set on COOL and the Temperature control thermostat

set to DECREASE.

Compressor (B1) starts.

To prevent compressor overload and damage during startup, solenoid valve (K4) is open at start of cooling

cycle to equalize pressure on both sides of the compressor.

The compressor (B1) takes cold, low pressure refrigerant gas and compresses it to a high temperature,

high pressure gas. This gas flows through the metal tubing to the condenser coil (C) and receiver (R1).

The condenser fans draw outside ambient air over and through the condenser coil (C). The high tempera-

ture, high pressure gas from the compressor (B1 ) is cooled by the flow of air and is changed into a high

pressure liquid.