TM 9-4120-398-14

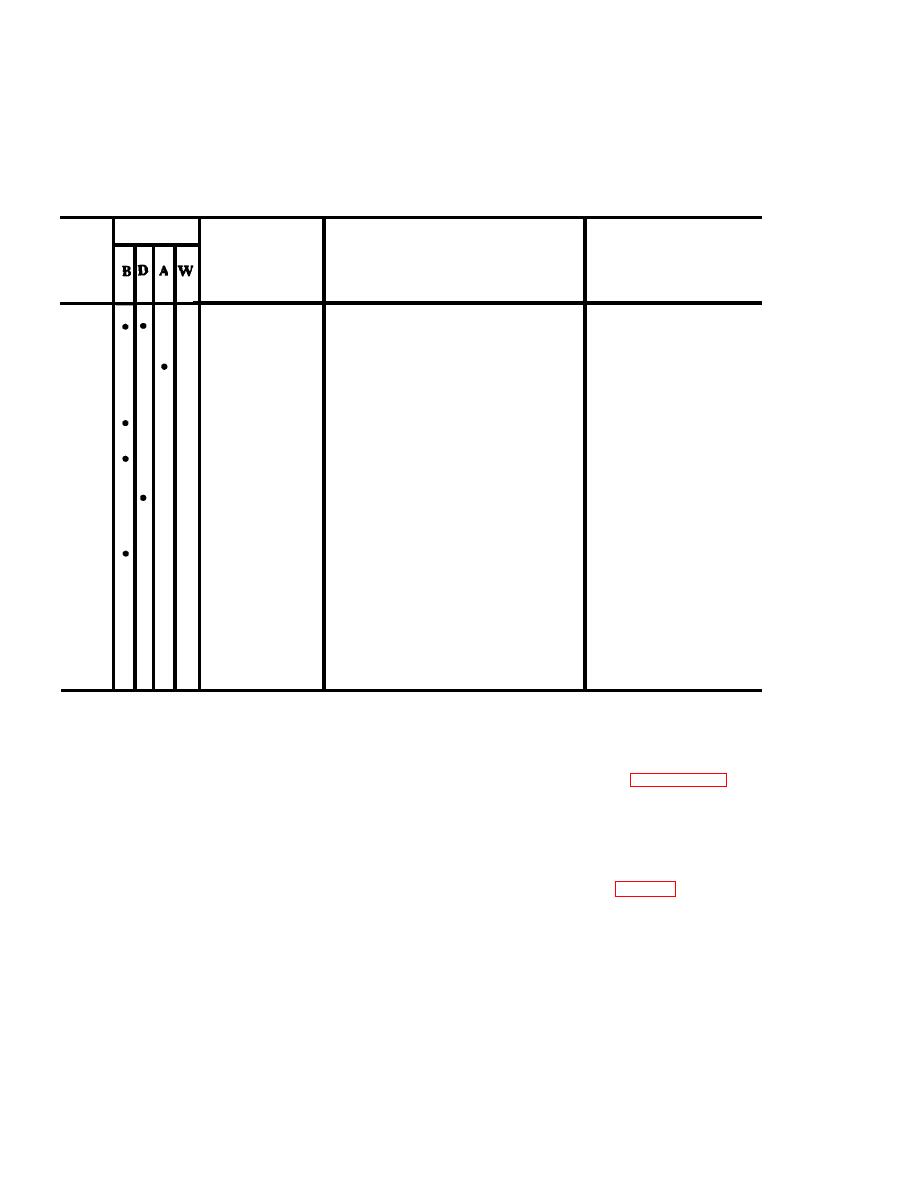

TABLE 2-1. OPERATOR PREVENTIVE MAINTENANCE CHECKS AND SERVICES - Continued

A - After

B - Before

W Weekly

D - During

Item

Item To Be

Interval

Equipment Is Not

Procedures

No.

Inspected

Ready/Available If:

Check for and have

repaired or adjusted

as necessary

Fresh Air

control chain

5

Check for proper adjust-

Damper

ment.

broken, missing

or inoperable.

Check for freedom of

operation.

Drain Hose

Water collecting.

6

Check for water collection.

Control panel

7

External

Check for obvious damage

Control Panel

and missing knobs.

damaged.

Unit not operating

Check for proper operation.

properly.

Bubbles or milky

Sight Liquid

8

After 15 minutes of oper-

Indicator

flow is observed.

ation in maximum cooling,

check for bubbles or milky

flow indicating low refrig-

erant charge. Check for

yellow color which indi-

cates presence of moisture.

Section III. OPERATION UNDER USUAL CONDITIONS

Services of Unit Maintenance should be employed for

ASSEMBLY AND PREPARATION FOR USE.

original unpacking, assembly installation, preparation for use, and other setup procedures. See paragraphs 4-2 thru 4-9.

INITIAL ADJUSTMENTS AND CHECKS

a. Inspect all covers, panels, grilles, and screens for loose mounting, obstructions, or shipping damage. Report any

deficiencies to unit maintenance.

b. Perforrn the before operation preventive maintenance checks and services listed in table 2-1.