TM 9-4120-405-13&P

2-5. LEAKAGE TEST. It is necessary for you to know how fluid leakage affects the status of your equipment. The

following definitions of the types/classes of leakage you need to know to be able to determine the status of your

equipment. Learn, then be familiar with them and REMEMBER WHEN IN DOUBT, NOTIFY YOUR SUPERVISOR.

Leakage Definitions:

Class I

Seepage of fluid (as indicated by wetness or discolor ation) not great

enough to form drops.

Class II

Leakage of fluid great enough to form drops but not enough to cause

drops to drop from item being checked/inspected.

Class III

Leakage of fluid great enough to form drops that fall from the item being

checked/inspected.

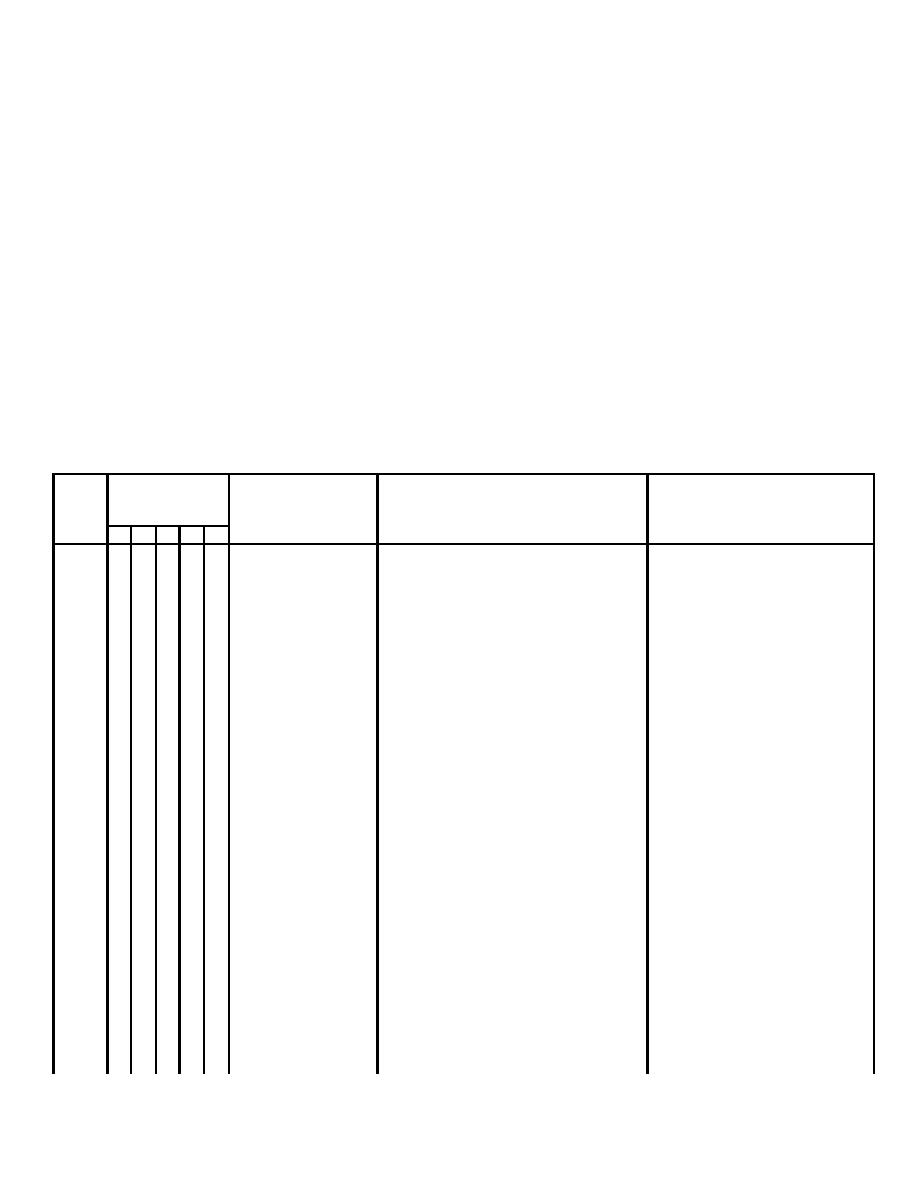

Table 2-1. Operator Preventive Maintenance Checks and Services

B - BEFORE

D - DURING

A - AFTER

W - WEEKLY

M - MONTHLY

Procedures:

Interval

Check for and have

Equipment is

Item

Item to be

repaired, filled or adjusted

Not Ready/

No.

B D A WM

Inspected

as needed

Available If:

AIR CONDITIONER

1

Information Plates

Check for legibility and loose or

missing hardware.

2

Fabric Cover

Check that cover is rolled up for

normal operation.

Roll down cover and check for

Cover is missing or dam-

condition of snaps, mildew, tears,

aged.

or worn edges.

3

Panels

Check for cracks, dents, or missing

Panels missing or dam-

hardware.

aged.

4

Air Filter

Check that filter is clean.

Filter is clogged or missing.

5

Vent Control

Check for proper adjustment.

Should be in closed position.

Freedom of operation.

Control wheel missing or

inoperable.

6

Condensate Drain

No water dripping anywhere

Water is leaking in an

except drain.

area that would cause

damage or be a hazard.

2-6