TM 9-4120-405-13&P

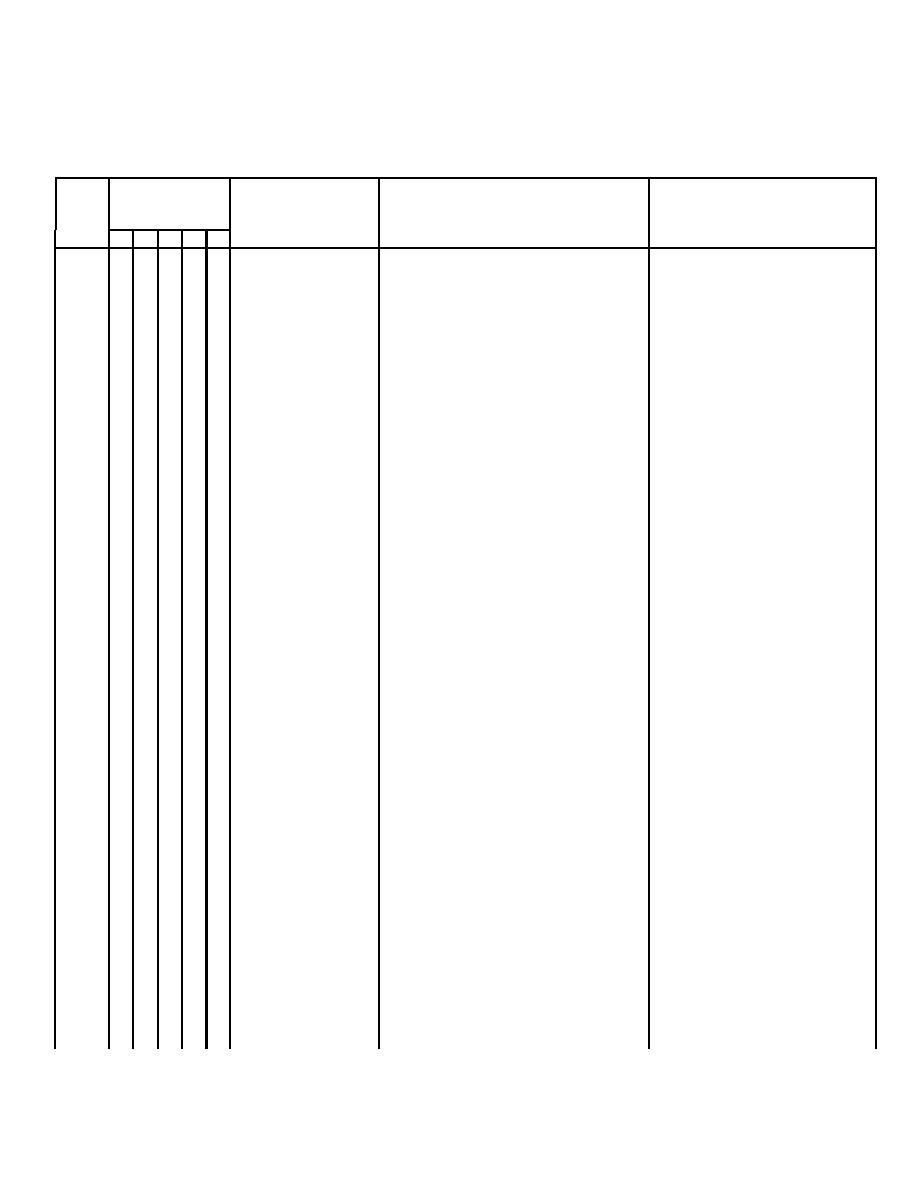

Table 2-1. Operator Preventive Maintenance Checks and Services (cont.)

B - BEFORE

D - DURING

A - AFTER

W - WEEKLY

M - MONTHLY

Procedures:

Interval

Check for and have

Equipment is

Item

Item to be

repaired, filled or adjusted

Not Ready/

No.

BDAWM

Inspected

as needed

Available If:

17

Fuel Tank

Drain water and sediment. Allow

to drain until fuel runs clean. Fill

tank upon completion of operation.

18

Primary Fuel Filter

Clean filter housing and replace filter

element (Refer to TM 5-6115-585-12).

19

Secondary

Clean filter housing and replace filter

Fuel Filter

element. (Refer to TM 5-6115-585-12).

TRAILER

20

Tires

a. Check that tire pressure is 35

One tire is flat, missing,

psig (241.22 kPa) when tires are

or unserviceable.

cool.

b. Check tires for cuts, foreign

objects, or unusual tread wear.

Remove any stones from between

the treads.

21

Wheels

NOTE

The left and right stud nuts are

turned clockwise to tighten and

counterclockwise to loosen.

Check wheels for damage and

One wheel is damaged.

wheel stud nuts for tightness and

One wheel stud nut

presence.

loose or missing.

22

Drawbar Ring

Check drawbar ring for secure

Ring is loose or bent.

mounting and obvious damage.

23

Intervehicular Cable

Check intervehicular cable for cuts

and breaks.

24

Safety Chains

Check safety chains for secure

Safety chains are missing

mounting and obvious damage.

or unsecure.

2-9