TM 9-4120-405-13&P

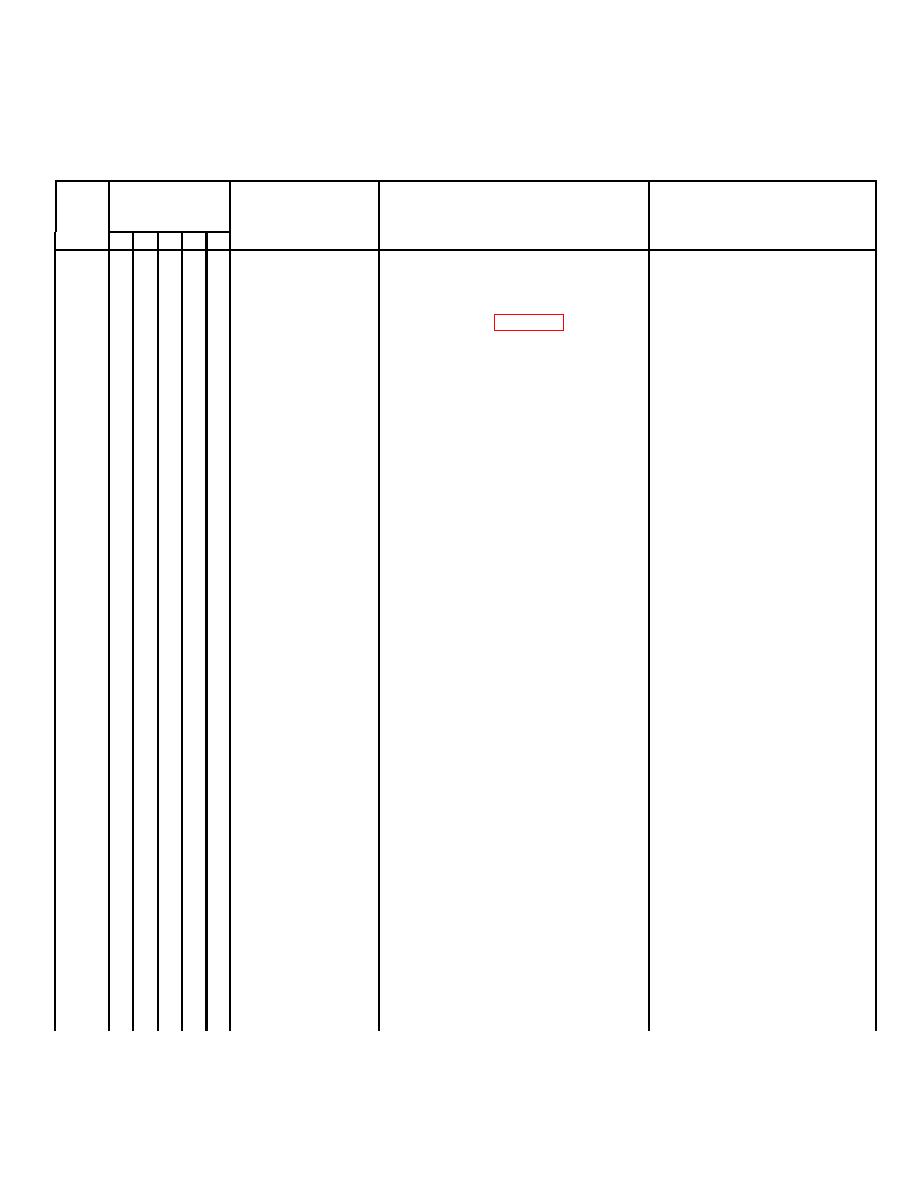

Table 2-1. Operator Preventive Maintenance Checks and Services (cont.)

B - BEFORE

D - DURING

A - AFTER

W - WEEKLY

M - MONTHLY

Procedures:

Interval

Check for and have

Equipment is

Item

Item to be

repaired, filled or adjusted

Not Ready/

No.

BDAWM

Inspected

as needed

Available If:

7

Control Module

Inspect for damage, secure

Control module dam-

mounting, and proper operation in

aged or operating

accordance with para. 2-8.

improperly.

8

Refrigerant Sight

After 15 minutes of operation in

Bubbles, milky flow, or

Glass

maximum cooling, check for bubbles

yellow color is observed.

or milky flow indicating low

refrigerant charge. Check for yellow

color which indicates presence of

moisture.

9

Flexible Ducts and

Check for obstruction, damage,

Flexible duct missing or

Adapters

proper adjustment, loose or missing

damaged beyond repair.

duct or hardware.

GENERATOR-SET

10

Generator-Set

a. Check on, around, and beneath

Any fuel leaks are

the generator-set for fuel or oil

detected.

leaks.

Class III oil or fuel leaks

detected.

b. Check that generator-set is

Not properly grounded.

properly grounded.

c. Check for secure connections

Loose or missing parts

frayed or damaged

ground wire.

CAUTION

Dangerous gases. Do not

smoke or use open flame

while servicing battery due to

possible presence of hydrogen,

a highly explosive gas.

d. Check battery electrolyte level.

Level should be about 3/8 in.

above top of plates. Add water if

level is low. Use clean water

(distilled water if available).

2-7