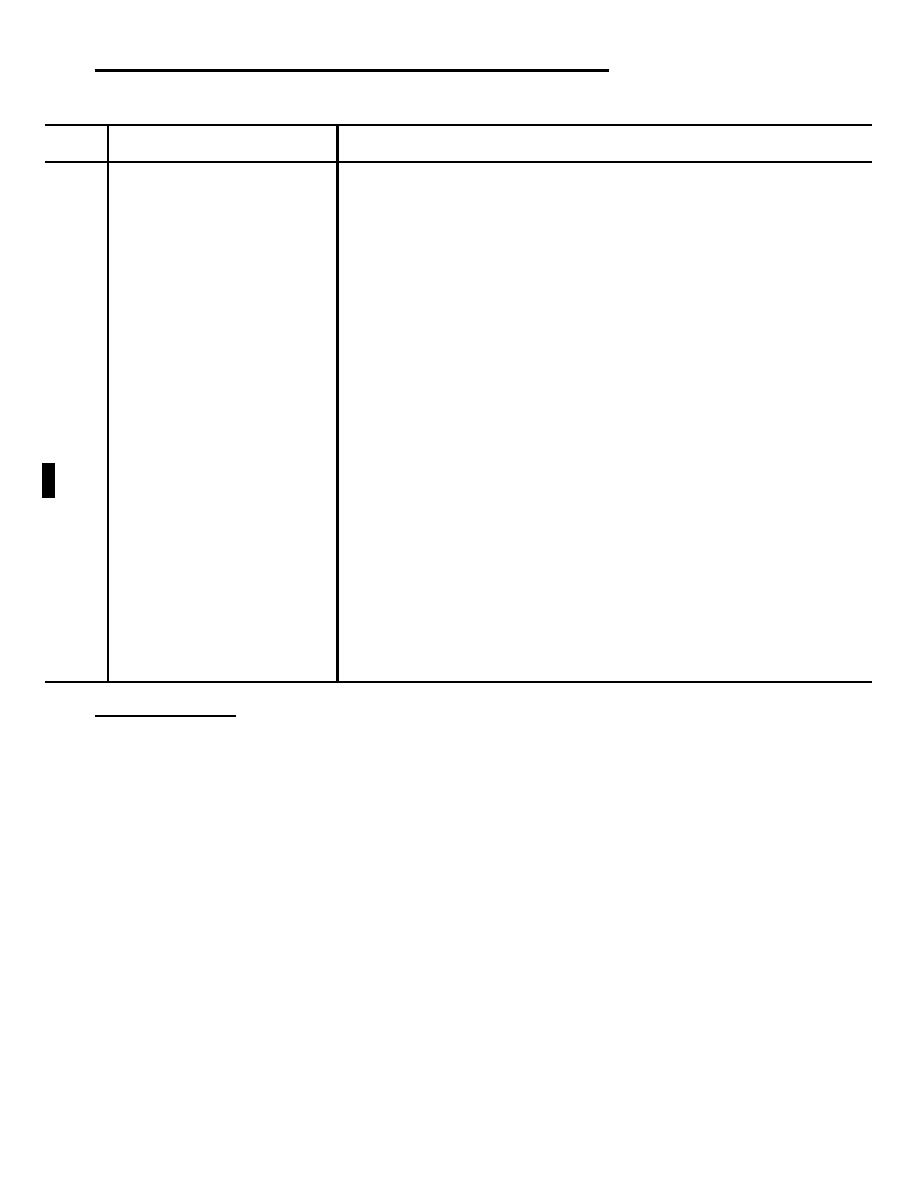

1-13. LOCATION AND DESCRIPTION OF MAJOR COMPONENTS. (Continued)

Table 1-4. Description of, Major Components, Evaporator Assembly (Continued).

Item

Item Name

Description and Purpose

No.

3

Thermoexpansion Valve (TEV)

Meters refrigerant flow and converts hot high-

pressure liquid to a cold low-pressure liquid.

Controlled by refrigerant temperature and

pressure in the evaporator and TEV sensing bulb.

TEV opening is governed by evaporator

temperature. As the evaporator warms, the TEV

opens allowing a rapid flow of liquid in the

evaporator, speeding up cooling. As the

evaporator cools, the TEV closes restricting

refrigerant flow in the evaporator, slowing down

cooling.

4

Differential Pressure Switch

Monitors the cleanliness of the air filter and

illuminates an indicator light on the control

module when filter is dirty.

5

Evaporator Coil

Absorbs heat through the vaporization of low-

pressure liquid. A low-pressure vapor is

discharged from the coil.

6

Low-Pressure Cut Out Switch

Shuts off compressor and illuminates a control

module indicator light when the pressure drops

to 27 3 psi (186 21 kPa).

7

EMI Filter and EMI Gasket

Dissipates and prevents EMI from affecting the

operation of other electronic equipment located

within close proximity.

8

Handle

Allows two people to lift evaporator assembly.

9

Terminal Board, Single Row

Allows for ease of troubleshooting and repair.

10

Condensate Drain Pan

Collects condensation from coil and discharges

through drain hole.

11

Evaporator Fan Motor

Drives Evaporator Housing Fan.

12

Evaporator Fan Housing

Draws air across evaporator coil to increase

heat transfer from refrigerant.

1-14. EQUIPMENT DATA.

OPERATING TEMPERATURES

-25 (-32 )

Low

F

C

+120 (+49 )

High

F

C

PERFORMANCE

Cooling capacity

30,000 BTUH

POWER REQUIRED

Voltage

28vdc

Amperes

66

Watts, Running (Maximum)

1,848

DIMENSIONS

CONDENSER ASSEMBLY

Width

33.00 in.

(83.82 cm)

Depth

20.00 in.

(50.80 cm)

Height

22.25 in.

(56.52 cm)

Weight (Maximum) 200 lb (91 kg)

Change 1

1-8