TM 9-4120-411-14

4.6.4 Corrosion Prevention Control. If a corrosion problem is identified, it can be reported using Standard Form 368,

Production Quality Deficiency Report. The form should be submitted to the address specified in DA Pam 738-750. This

will result in more definitive actions being taken to prevent future occurrences.

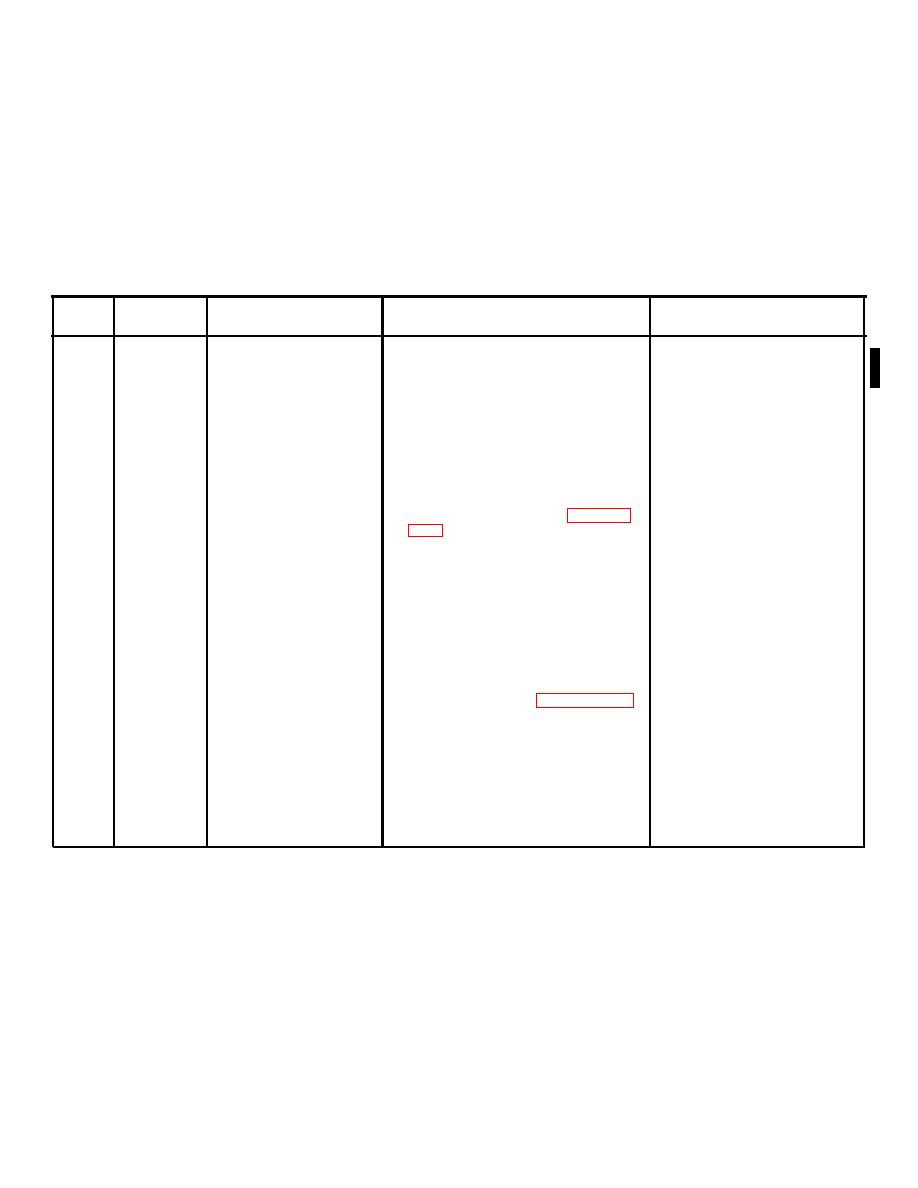

Table 4-1. Unit Preventive Maintenance Checks and Services for FDECU.

NOTE

If the FDECU must be kept in operation during a scheduled PMCS interval, perform

only those procedures that will not disturb operation then perform remaining

procedures when the unit can be shut down.

Item

Interval

Item to be

Procedure

"Not Fully Mission

No.

Checked or Serviced

Capable If":

1

Quarterly

Inside Blower

Examine inside blower then clean as nec- Inside blower dam-

essary and inspect for any cracks or other aged or dirty enough

damage. Replace if damaged.

to cause reduced air

flow.

2

Quarterly

Outside Fan

Clean outside fan as necessary and in-

Outside fan is dam-

spect for any cracks or other damage. Re- aged or dirty enough

place if damaged.

to cause reduced air

flow.

3

Quarterly

Condensate Drain

a. Remove supply panel per paragraph

Condensate drain

Hose

hose obstructed.

b. Examine condensate drain hose for

any obstruction. Clean as indicated.

4

Semi-

Wires, Cables, Har-

a. Open cover a nd panels as necessary

Any wire, cable, or

annually

nesses, and Electri-

to access component connections.

harness is damaged.

cal Connections

b. Check wires, cables, and harnesses

Any electrical connec-

for breaks, cuts, or frayed insulation.

tion is loose, missing,

c. Check that all electrical connections

or damaged.

are secure. Tighten if necessary. If

terminals are missing or damaged,

repair or replace per paragraph 4.16.

5

Semi-

Electrical System

a. Open cover and panels as necessary

Electrical system com-

annually

Components

to access components.

ponent damaged or

b. Check components for damage or

overheated.

evidence of overheating. Replace

any damaged components per ap-

propriate procedure.

Change 1 4-15