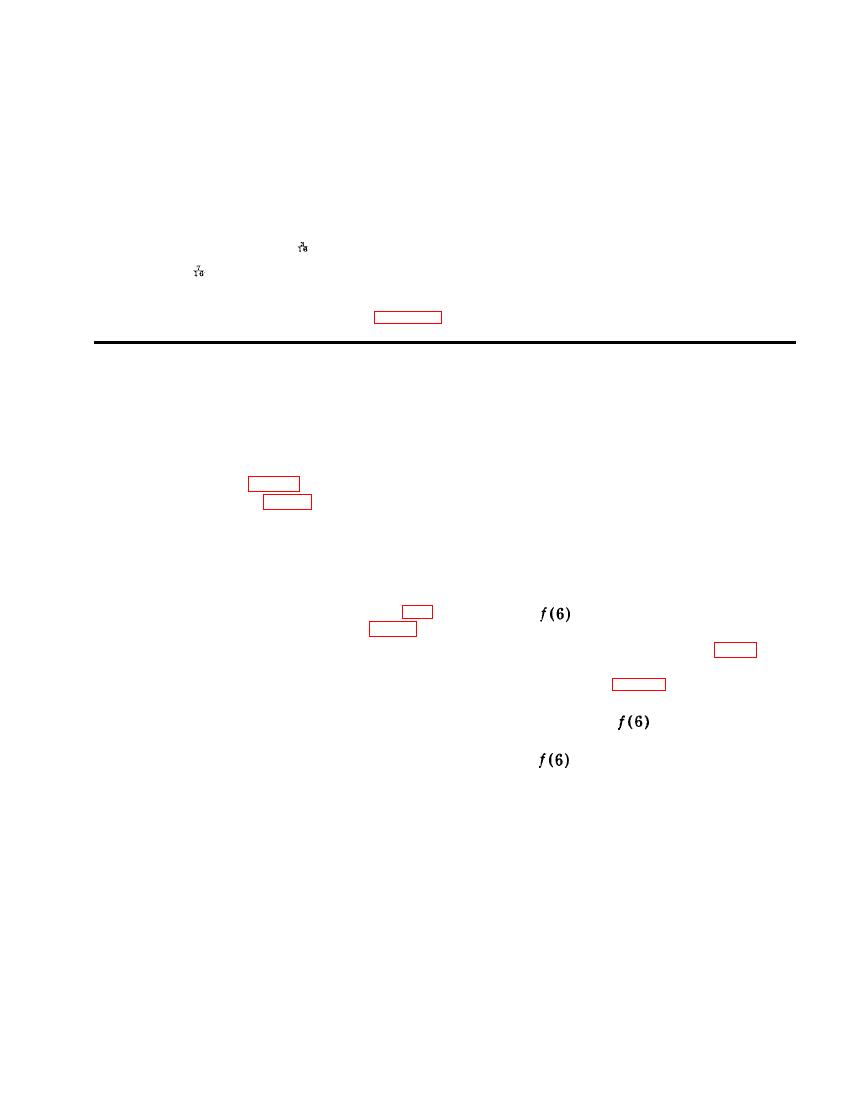

1

- No. 6-32NC-2 x screw

19 - No. 6-32NC-2 x 1 screw

2

- No. 6 lockwasher

20 - No. 6 lockwasher

3

- 0.148-in. id plain washer

21 - Coil pot end plate

4

- Insulating washer

22 - Coil core

5

- Short bushing-type insulator

23 - Paralleling coil

6

- Contact screw plate

24 - Operating coil

7

- Contact screw plate insulator

25 - Coil pot

26 - Shim

8

- Contact screw assembly

9

- Carbon pile tube

27 - Armature assembly

10

- Carbon pile

28 - -in. pipe plug

11

- Carbon pile support

29 - Cover

12

- Tab lockwasher

30 - Long bushing-type insulator

13

- No. 6 lockwasher

31 - Contact screw cable

14

- No. 6-32NC-2 x

screw

32 - Spacer

15

- Support O-ring gasket (packing)

33 - Bimetal ring

16

- -in. od plain washer

34 - No. 6-32NC-2 x screw

17

- No. 10 lockwasher

35 - No. 6 lockwasher

18

- No. 10-32NF-2 x screw

Figure 59 - Continued.

(full increase) and then turning

(4) should be 28 volts plus or minus

these adjustments fully clockwise

0.2 volts.

(full decrease). Voltage reading on

(d)

Turn the variable load 0-25 0-12.5

the dc voltmeter (4) should be 25.5

ampere rheostat (19) fully coun-

to 29.5 volts. If the voltage range

terclockwise.

Place one of the

is incorrect, adjust by loosening the

100-50 fixed load switches (17-A)

screw (T, fig. 59) and turning the

in the "ON" position. The voltage

coil core (8, fig. 58). If the voltage

reading on the dc voltmeter (4)

is too high, turn the coil core clock-

should be 27.7 plus or minus 0.3

wise. If the voltage is too low, turn

volts. Place the 100-50 fixed load

the coil core counterclockwise. Set

switch (17-A) in the "OFF" posi-

the voltage at 28.0 volts by adjusting

tion.

the 5-ohm adjustable resistor as-

assembly,

(e)

Stop the

varidrive

sembly with the adjustment (fig.

(a) above, and remove the gen-

57). Tighten the screw (T, fig. 59).

e r a t o r (alternator) from the low

C o n t i n u e with the tests in (4)

speed driving head (5, fig. 7) and

below.

place it on the high speed driving

head (4, fig, 7). Recalibrate the

(4) Checking performance.

tachometer indicator circuitry ac-

(a) Turn the speed control handle (24)

(b) above.

cordingly,

clockwise until 2000 rpm are indi-

assembly

S t a r t t h e varidrive

cated on the tachometer indicator

(f)

meter (3).

(c) above, and turn the speed

control handle (24) clockwise until

4,000 rpm are indicated on the ta-

tor) regulator by placing the 100-50

fixed load switch (17-A) in the

chometer indicator meter (3) and

r e p e a t tests in (b) t h r o u g h ( d )

"ON" position and then the "OFF"

position several times. Place the

above. The voltage reading for the

10 ampere reading, (c) above, should

100-50 fixed load switch (17-A) to

the "OFF" position but leave the

be 27.9-28.3 volts and the voltage

battery on-off switch (22) in the

reading for the 100-50 fixed load,

(d) above, should be 27.3-28.3 volts.

"ON" position.

(c) Turn the variable load 0-25 0-12.5

Turn the speed control handle (24)

(g)

ampere rheostat (19) clockwise un-

clockwise until 8,000 rpm are indi-

til 10 ampere reading is indicated

cated on the tachometer indicator

meter (3) and repeat tests in ( b )

on the load dc ammeter (1). The

t h r o u g h (d) above. The voltage

voltage reading on the dc voltmeter

123