TM 9-4910-579-14&P

LAPPING THE ROUGHING TOOL

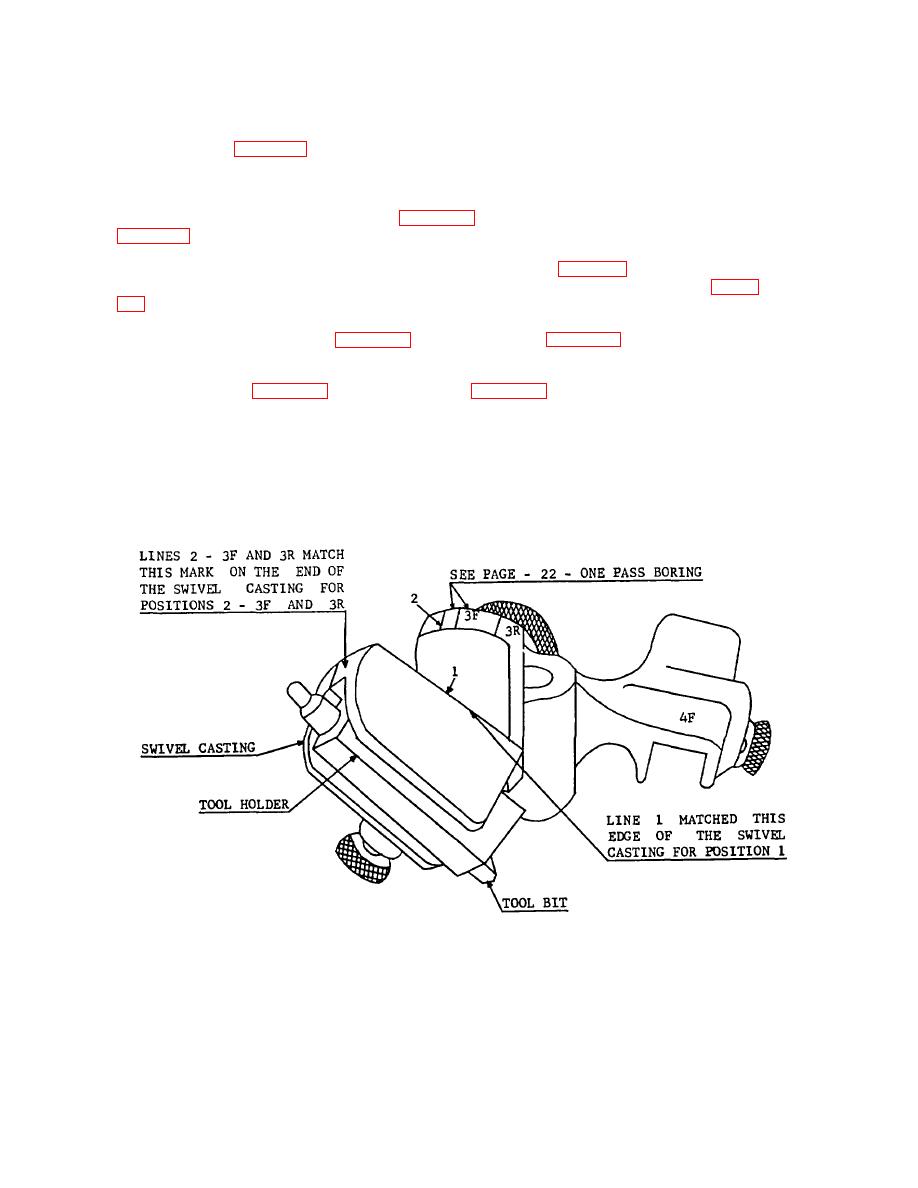

On the roughing tool, Figure - 5 -, a part of portion 1 and all of portion 2 remove the metal in boring

and are, therefore, the parts of the tool that wear and must be reconditioned. The lapping

operations will be as follows:

1- The first operation is to lap the tool face, Figure - 5 -, by using the small lapping jig shown in

2- Then place the tool holder in the large lapping jig as shown in Figure 7 and set the swivel

casting that holds the tool to position 1 as illustrated. Lap in this position until portion 1, Figure

- 5 -, is smooth.

3- Shift swivel casting to position 2, Figure - 7 -, and lap portion 2, Figure - 5 - until portion 2 is in

good condition.

4- Shift to position 3R, Figure - 7 -, and lap portion 3R, Figure - 5 -, until 2 has the proper width.

For roughing tool, this width should be eight thousandths for the average size bore.

Under ordinary conditions, the roughing tool will bore six cylinders without relapping. There are

exceptions, however, when the tool should be lapped more often, due to hard material or large and

long bores. Examine the tool after each hole to check its condition. A sharp free-cutting tool

requires less power and maintains consistent hole size so time spent in touching up the tool will

improve results.

PAGE - 22

FIGURE 7

LARGE LAPPING JIG SHOWING THE DIFFERENT

POSITIONS FOR LAPPING THE TOOL

- 12 -